| “This site contains affiliate links for which OEMDTC may be compensated” |

BR004–00

October 20, 2000

Title:

BRAKE PAD CLICKING NOISE

Models:

’90 – ’00 All Models

Introduction

A clicking type noise may be noticed when first applying the brakes after changing vehicle travel direction (Drive/Forward to Reverse, Reverse to Drive/Forward). This is a normal noise caused by the required brake pad–to–caliper clearances. When the direction of travel is changed, the brake pads may “shift” towards the new direction of travel. When the brake pad contacts the caliper, a clicking noise may be heard.

To minimize this clicking noise, a disc brake caliper grease has been made available for use during brake service/maintenance operations. Under normal usage conditions this grease should be effective for a period of 6 months to 1 year.

Applicable Vehicles

- 1990 – 2000 model year Toyota

vehicles, all models.

vehicles, all models.

Parts Information

| PREVIOUS PART NUMBER | CURRENT PART NUMBER | PART NAME |

|---|---|---|

| N/A | 08887-80609 | Disc Brake Caliper Grease (50 g tube) |

Warranty Information

| OP CODE | DESCRIPTION | TIME | OPN | T1 | T2 |

|---|---|---|---|---|---|

| N/A | Not Applicable to Warranty | – | – | – | – |

Application Procedure

There are two types of brake calipers: floating and fixed. Check the type of brake caliper installed on the vehicle by removing the wheel assembly.

- Floating Type Brake Caliper

A. Lift up or remove the brake caliper and suspend it securely.

| HINT:

Do not disconnect the flexible hose from the brake caliper. |

B. If equipped with anti–squeal spring: Remove the anti–squeal springs.

C. Remove the brake pads with anti–squeal shims.

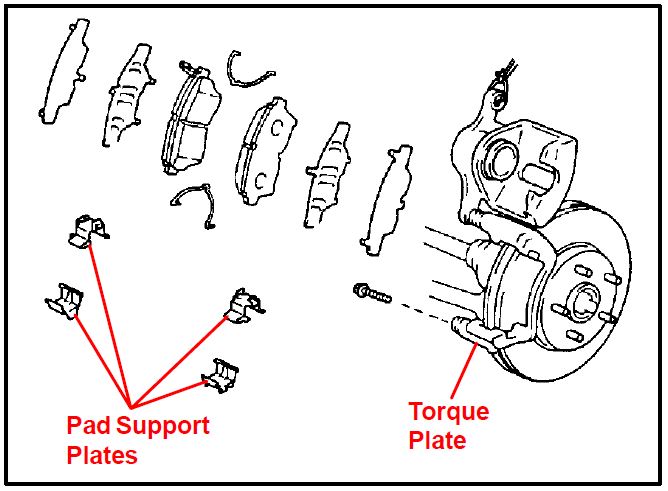

D. Remove the pad support plates from the torque plate. Clean any dust from the pad support plates, torque plates and brake pads.

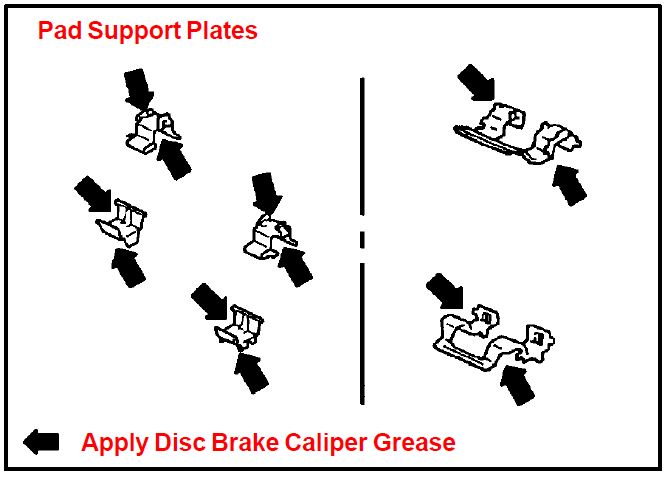

E. Apply a small amount of the disc brake caliper grease (1–2 mm thick) to both sides of the pad support plates.

| NOTE:

Do NOT apply grease to the friction surfaces of the brake pads or the disc rotor. |

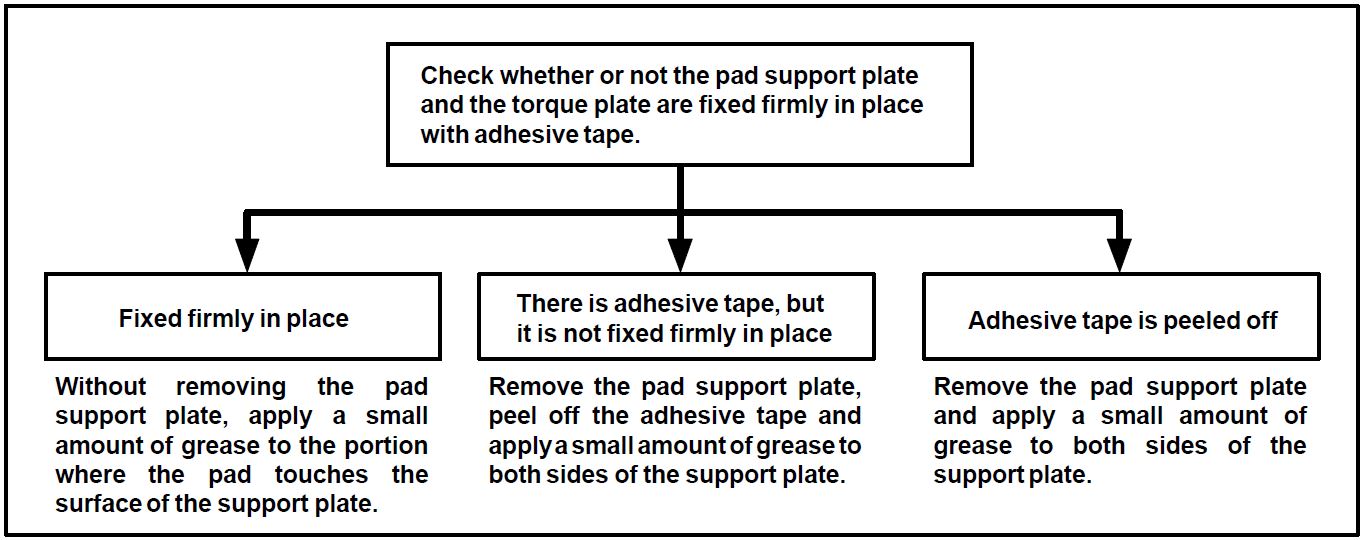

F. If the pad support plate is fixed to the torque plate with adhesive tape, perform the operation according to the following flow chart.

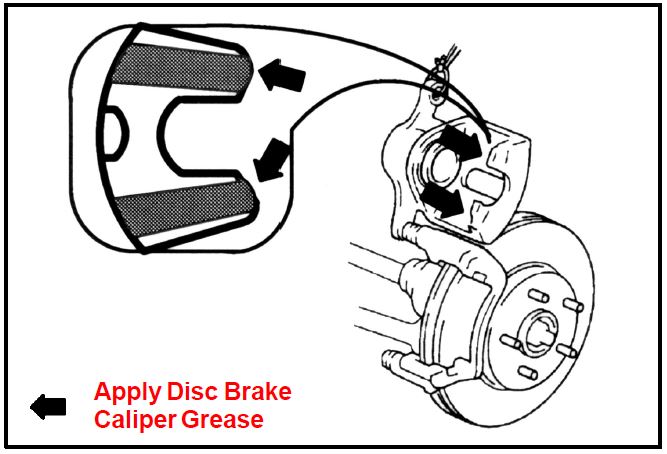

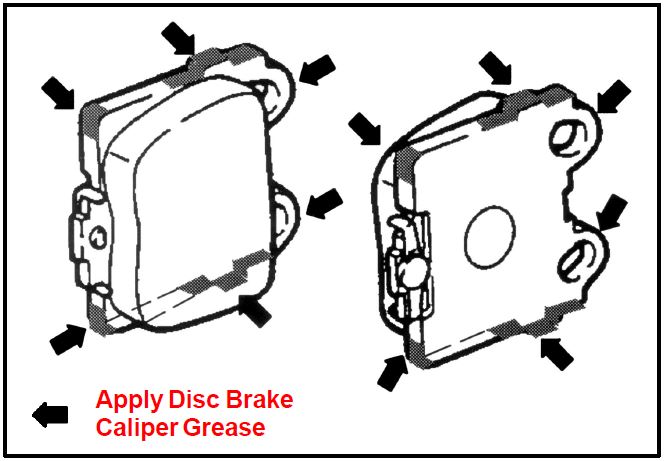

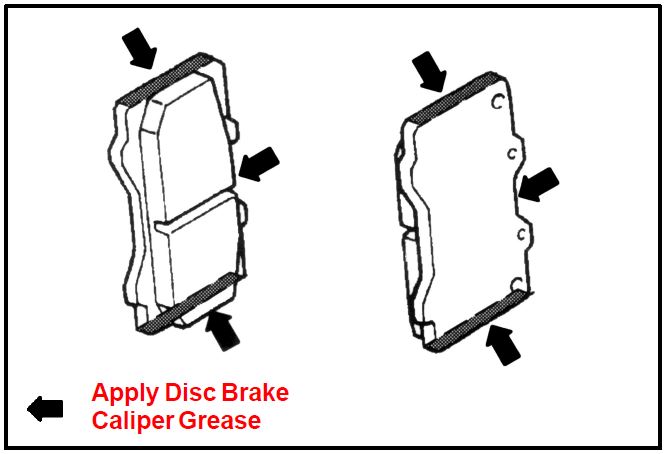

G. Apply a small amount of the disc brake caliper grease (1–2 mm thick) to the caliper as indicated in the illustration.

H. Install the brake pads with the anti–squeal shims.

I. If equipped with anti–squeal spring: Install the anti–squeal springs.

J. Press the piston in firmly and install the brake caliper.

NOTE:

|

K. Install the wheel assembly.

- Fixed Type Brake Caliper

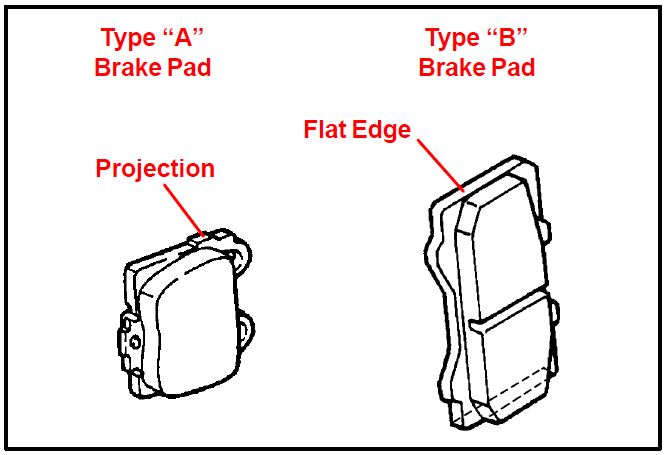

There are two types of brake pads:

- Type “A”: Has a projection on the upper and lower side of the brake pad. (See illustration.)

- Type “B”: Has a flat upper and lower edge on the brake pad backing plate.

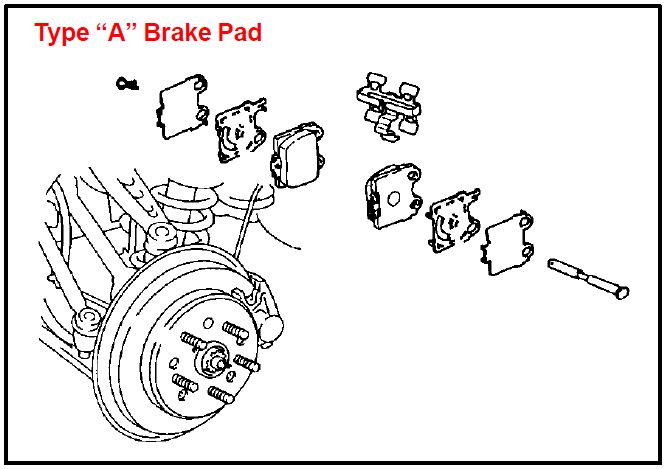

Type “A” Brake Pad

A. Remove the anti–squeal spring,clip and pad guide pin.

B. Remove the brake pads with the anti–squeal shims.

C. Clean any dust from the brake pads.

D. Apply a small amount of the disc brake caliper grease (1–2 mm thick) to the areas indicated in the illustration.

| NOTE:

Do NOT apply grease to the friction surfaces of the brake pads or the disc rotor. |

E. Install the brake pads with the anti–squeal shims.

| NOTE:

Clean excess grease from the brake pads and caliper. |

F. Install the pad guide pin, clip and anti–squeal spring.

G. Install the wheel assembly.

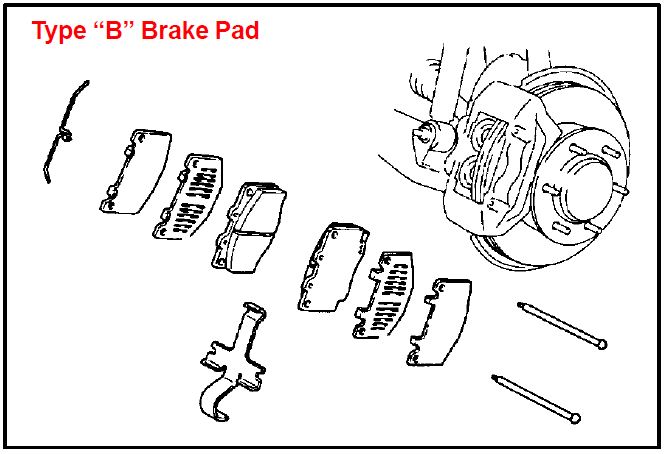

Type “B” Brake Pad

A. Remove the clip, pins and anti–rattle spring/pad retainer clip.

B. Remove the brake pads with the anti–squeal shims.

C. Clean any dust from the brake pads.

D. Apply a small amount of the disc brake caliper grease (1–2 mm thick) to the areas indicated in the illustration.

| NOTE:

Do NOT apply grease to the friction surfaces of the brake pads or the disc rotor. |

E. Install the brake pads with the anti–squeal shims.

| NOTE:

Clean excess grease from the brake pads and caliper. |

F. Install the pad guide pin, clip and anti–squeal spring.

G. Install the wheel assembly.

Loading...

Loading...