| “This site contains affiliate links for which OEMDTC may be compensated” |

BR004-07

August 24, 2007

Title:

FRONT BRAKE SQUEAK

Models:

’03 – ’07 Corolla & Matrix (NAP)

TSB REVISION NOTICE:

|

Introduction

Some customers may experience front brake squeak noise when the car is traveling in reverse at low speeds. Updated front disc brake cylinder (caliper) mountings and disc brake pad support plates are available to improve this condition.

Applicable Vehicles

- 2003 – 2007 model year Corolla and Matrix NAP-built vehicles produced BEFORE the Production Change Effective VINs shown below.

Production Change Information

| MODEL | PLANT | PRODUCTION CHANGE EFFECTIVE VIN |

|---|---|---|

| Corolla | NUMMI | 1NXBR32E#7Z920892 |

| TMMC | 2T1BR32E#7C838401 | |

| Matrix | TMMC | 2T1KR32E#7C679540 |

Warranty Information

| OP CODE | DESCRIPTION | TIME | OFP | T1 | T2 |

|---|---|---|---|---|---|

| 473301 | Front Disc Brake Pad and/or Disc Brake Pad Shim (Both Sides) | 0.8 | 47721–02140 | 91 | 13 |

| Applicable Warranty*:

This repair is covered under the Toyota |

* Warranty application is limited to correction of a problem based upon a customer’s specific complaint.

Parts Information

| NOTE:

ALL parts MUST be replaced as a set. |

| PREVIOUS PART NUMBER | CURRENT PART NUMBER | PART NAME | QTY |

|---|---|---|---|

| 47721-02140 | 47721-02141 | Mounting, Disc Brake Cylinder (Pad Holder/Caliper Mount) LH & RH | 2 |

| 47716-02100 | 04947-02120 | Plate, Pad Support , Kit | 1 |

| 47717-02050 | |||

| 47775-02090 | Same | Boot, Bushing Dust | 4 |

| 08887-80609 | Same | Disc Brake Caliper Grease (50 g tube) | 1 |

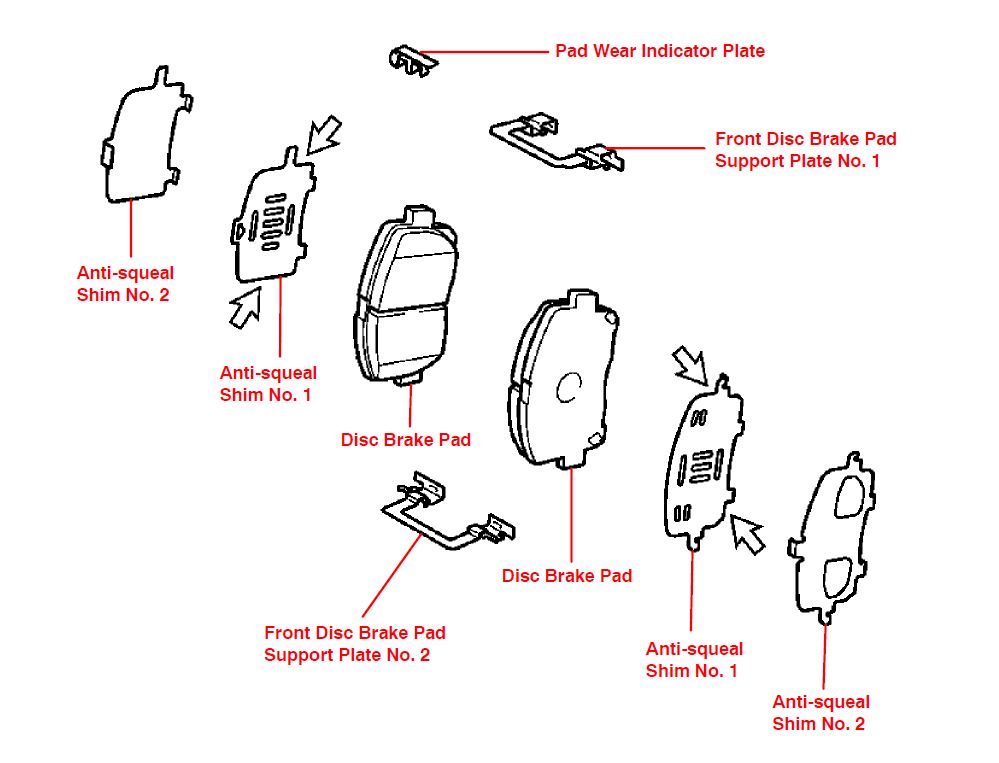

Components

Repair Procedure

- Conduct a road test to verify the noise condition — noise usually occurs when backing out of a parking space and/or turning in reverse.

- Remove and replace the front disc brake pad support plate (2 per each caliper).

NOTE:

|

A. Remove the front wheel.

B. Remove the caliper by holding the front disc brake slide pin and removing the 2 bolts.

C. Remove the 2 front brake pads from the front disc brake cylinder mounting.

D. Remove the anti-squeal shims and the pad wear indicator plates from each pad.

E. Remove the 2 front disc brake pad support plates from the cylinder mounting.

F. Remove the front disc brake cylinder mounting plate by removing the 2 bolts.

G. Install the NEW disc brake cylinder mounting plate with the 2 bolts.Torque: 107 Nm (1089 kgf cm, 79 ft lbf)

H. Install the 2 NEW disc brake pad support plates.

Apply disc brake grease to the back of the brake pad support plate.

I. Install the front anti-squeal shims.

a. Apply disc brake grease to the anti-squeal shims.

NOTE:

|

b. Install the anti-squeal shims and the pad wear indicators to each pad.

| NOTE:

Install the pad wear indicators in the correct positions and directions. |

J. Install the 2 front brake pads with anti-squeal shims to the disc brake cylinder mounting.

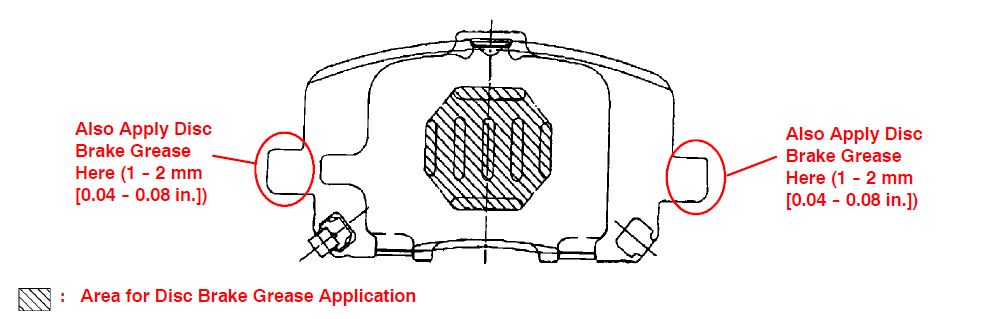

Apply a small amount of the disc brake grease (1 — 2 mm [0.04 — 0.08 in.] thick) to the areas shown in the illustration.

| NOTE:

Do NOT apply grease to the friction surfaces of the brake pads or the disc rotor. |

K. Install the caliper with the 2 bolts.

Torque: 34 NSm (350 kgfScm, 25 ftSlbf)

L. Install the front wheel.

Torque: 103 NSm (1,050 kgfScm, 76 ftSlbf)

- Road test the vehicle to confirm the front brake “squeak” noise is NO longer present.

Loading...

Loading...

- Provides an extra margin of safety in extreme braking conditions

- Mix of polyglycol ethers ensures hot brake-system operation will not create dangerous vapor

- Excellent for ABS, disc and drum brake systems

- Delivers braking power when needed by avoiding a spongy pedal

- Both wet and dry boiling points exceed the minimum government standards

- High compatibility. Use with or direct replacement for DOT 3, DOT 4, and DOT 5. 1

- Extended Service Interval (ESI): Lasts 100 percent longer than DOT 3, 50 percent longer than DOT 4, and 10 percent longer than DOT 5. 1

- Exceeds all DOT 3, DOT 4, and DOT 5. 1 standards

- Wet boiling point ~ 365 DegreeF/Viscosity at -40 DegreeC ~ 685mm2/s

- Standard brake fluid has a recommended change interval of 2 years. The recommended change interval for Bosch ESI6 is 3 years.

- Premium DOT 3 Brake Fluid has a minimum boiling point of 450°F

- Meets and exceeds DOT 3 and all other Federal and SAE specifications and standards for motor vehicle brake fluids

- Mixes with all DOT 3 approved brake fluids

- Designed for use in disc, drum and ABS brake systems

- Premium brake and hydraulic clutch fluid that protects internal components from corrosion under normal use

- High boiling point to minimize brake fluid boiling and vapor lock

- Excellent low temperature capability and stability when used where lower cold viscosities are required

- Excellent low temperature capability and stability when used where lower cold viscosities are required

- Synthetic quality brake fluid

- Contains special ingredients to guard against vapor lock and moisture absorption

- Exceeds requirements for both DOT 3 and DOT 4 brake fluids

- Specially formulated for DOT 4 brake fluid applications

- Designed for use in disc, drum and ABS brake systems

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.

Comprehensive Warranty. This warranty is in effect for 36 months or 36,000 miles, whichever occurs first, from the vehicle’s in-service date.

Comprehensive Warranty. This warranty is in effect for 36 months or 36,000 miles, whichever occurs first, from the vehicle’s in-service date.