| “This site contains affiliate links for which OEMDTC may be compensated” |

June 26, 2019 NHTSA CAMPAIGN NUMBER: 19V491000

A loss of drive increases the risk of crash.

NHTSA Campaign Number: 19V491

Manufacturer Toyota Motor Engineering & Manufacturing

Motor Engineering & Manufacturing

Components HYBRID PROPULSION SYSTEM

Potential Number of Units Affected 464

Summary

Toyota Motor Engineering & Manufacturing (Toyota

Motor Engineering & Manufacturing (Toyota ) is recalling certain 2018-2019 Prius C vehicles. The DC-DC converter may fail resulting in the auxiliary battery no longer receiving power from the converter, which may cause a loss of drive.

) is recalling certain 2018-2019 Prius C vehicles. The DC-DC converter may fail resulting in the auxiliary battery no longer receiving power from the converter, which may cause a loss of drive.

Remedy

Toyota will notify owners, and dealers will replace the DC-DC converter with a new one, as necessary, free of charge. The recall began August 23, 2019. Owners may contact Toyota

will notify owners, and dealers will replace the DC-DC converter with a new one, as necessary, free of charge. The recall began August 23, 2019. Owners may contact Toyota customer service at 1-888-270-9371. Toyota

customer service at 1-888-270-9371. Toyota ’s number for this recall is K0K.

’s number for this recall is K0K.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Vehicle has a Recall

◄ IMPORTANT UPDATE ►

The attached Dealer Letter has been updated. Refer to the details below.

| DATE | TOPIC |

| 9/19/2019 | The sublets in the Warranty Reimbursement Procedure section have been updated. |

| 9/17/2019 | The maximum number of days for Loaner Vehicle sublet has been updated. |

| 8/20/2019 | Dealer Reimbursement Op Codes have been updated. |

The most recent update in the attached Dealer Letter will be highlighted with a red box.

Please review this notification with your staff to assure that all relevant personnel have been briefed regarding this subject.

Thank you for your cooperation.

Original Publication Date: August 14, 2019

To: All Toyota Dealer Principals, General Managers, Service Managers, and Parts Managers

Dealer Principals, General Managers, Service Managers, and Parts Managers

SAFETY RECALL K0K (Remedy Notice)

Certain 2018-2019 Model Year Prius C Vehicles

Potential Loss of Motive Power While Driving

NHTSA Recall No. 19V-491

| Model / Years | Production Period | Approximate Total Vehicles | Approximate Stop Sale Dealer Inventory |

| 2018 – 2019 Prius C | Early February 2018 – Early October 2018 | 500 | 8 |

| STOP! DO NOT SELL NEW VEHICLES IN DEALER INVENTORY.

Refer to Dealer Inventory Procedures section for more details. |  |

On June 26, 2019, Toyota filed a Defect Information Report (DIR) with the National Highway Traffic Safety Administration (NHTSA) informing the agency of our intent to conduct a voluntary Safety Recall on 2018 – 2019 model year Prius C vehicles.

filed a Defect Information Report (DIR) with the National Highway Traffic Safety Administration (NHTSA) informing the agency of our intent to conduct a voluntary Safety Recall on 2018 – 2019 model year Prius C vehicles.

Condition

Due to a manufacturing issue, a component may stop performing its function of converting power from the hybrid vehicle battery for use by certain vehicle systems. If this occurs, warning lights will illuminate, audible chimes will sound, and messages will be displayed on the instrument panel. If the vehicle continues to be operated, it could lose motive power. Loss of motive power while driving at higher speeds could increase the risk of a crash.

Remedy

Based on the vehicle identification number (VIN) or an inspection, any authorized Toyota dealer will replace the affected DC-DC converter with a new one, if necessary, FREE OF CHARGE.

dealer will replace the affected DC-DC converter with a new one, if necessary, FREE OF CHARGE.

Check Each VIN in TIS

Some involved vehicles have been identified as requiring a replacement of the DC-DC converter based on its VIN. Other involved vehicles will require an inspection first to determine replacement of the DC-DC converter is necessary. To determine if the vehicle requires inspection, please search each VIN using TIS and be sure to check the TIS Memo field (see below images for more detail). Only perform the repair that is required for the specific VIN. If replacement of the DC-DC Converter is performed on a vehicle that doesn’t require the repair, the claim will be subject to debit.

| Phase 1 – No Inspection is Required for DC-DC Converter Replacement |

| This vehicle requires the DC-DC Converter to be replaced based on VIN. No inspection should be performed. |

| Phase 2 – Inspection is Required for DC-DC Converter Replacement |

| This vehicle requires inspection first to determine if DC-DC Converter Replacement is necessary. |

Note: For more details and information regarding the inspection and repair procedure, please refer to the technical instructions.

Covered Vehicles

There are approximately 500 vehicles covered by this Safety Recall. Approximately 10 vehicles involved in this Safety Recall were distributed to Puerto Rico.

Owner Letter Mailing Date

Toyota will notify owners by mid-August 2019.

will notify owners by mid-August 2019.

Toyota makes significant effort to obtain current customer name and address information from each state through industry resources when mailing owner letters. In the event your dealership receives a notice for a vehicle that was sold prior to the Safety Recall announcement, it is the dealership’s responsibility to forward the owner letter to the customer who purchased the vehicle.

makes significant effort to obtain current customer name and address information from each state through industry resources when mailing owner letters. In the event your dealership receives a notice for a vehicle that was sold prior to the Safety Recall announcement, it is the dealership’s responsibility to forward the owner letter to the customer who purchased the vehicle.

Please note that only owners of the covered vehicles will be notified. If you are contacted by an owner who has not yet received a notification, please verify eligibility by confirming through TIS prior to performing repairs. Dealers should perform the repair as outlined in the Technical Instructions found on TIS.

Dealer Inventory Procedures

New Vehicles in Dealership Inventory

There are approximately 8 vehicles in new dealer inventory as of June 25, 2019.

| Under Title 49, Section 30112 of the United States Code, a dealer cannot sell, offer for sale, or introduce or deliver for introduction in interstate commerce a new motor vehicle when it is aware that the vehicle does not comply with an applicable Federal Motor Vehicle Safety Standard or contains a defect related to motor vehicle safety. Further, 49 Code of Federal Regulations §577.13 requires us to provide the following advisory: It is a violation of Federal law for a dealer to deliver a new motor vehicle or any new or used item of motor vehicle equipment (including a tire) covered by this notification under a sale or lease until the defect or noncompliance is remedied.

Toyota |

| Vehicle Safety Recall completion should always be verified through TIS. We request your assistance to ensure involved vehicles are identified and not delivered prior to performing the remedy. | |

NOTE:

- New vehicles in dealer inventory subject to a Safety Recall must be remedied before delivery into commerce under a sale or lease. Dealer-to-dealer trades as well as vehicle sales between dealers should not be made until a vehicle is remedied.

- Dealers can identify if any of their new and used inventory has any open campaigns in the Vehicle Inventory Summary available in Dealer Daily (https://dealerdaily.toyota.com/). The Vehicle Inventory Summary may take up to 4 hours to populate information for newly launched campaigns.

Inspection Reminder Mirror Hang Tags for Covered Vehicles in New Dealer Stock

To easily recognize vehicles involved in this Safety Recall, each dealership should utilize Inspection Reminder Hang Tags. Inside the vehicle’s glove box are stickers containing the VIN. Apply one of these stickers to the hang tag and install the hang tag in the vehicle. A sample copy of the Inspection Reminder Hang Tag has been included for your reference.

| Part Number | Description | Quantity |

| 00411-140003 | Inspection Mirror Hang Tag | 25 Per Pack |

NOTE: Dealerships can order hang tags from the Material Distribution Center (MDC).

Pre-Owned Vehicles in Dealer Inventory

To ensure customer satisfaction, Toyota requests that dealers complete this Safety Recall on any used vehicles currently in dealer inventory that are covered by this Safety Recall prior to customer delivery. However, if the campaign cannot be completed (for example, due to remedy parts availability), delivery of a covered vehicle is acceptable if disclosed to the customer that the vehicle is involved in a Safety Recall.

requests that dealers complete this Safety Recall on any used vehicles currently in dealer inventory that are covered by this Safety Recall prior to customer delivery. However, if the campaign cannot be completed (for example, due to remedy parts availability), delivery of a covered vehicle is acceptable if disclosed to the customer that the vehicle is involved in a Safety Recall.

Toyota expects dealers to use the attached Customer Contact and Vehicle Disclosure Form to obtain vehicle buyer information. Dealers are expected to provide a copy of the completed form, along with the most current FAQ, to the vehicle buyer. Toyota

expects dealers to use the attached Customer Contact and Vehicle Disclosure Form to obtain vehicle buyer information. Dealers are expected to provide a copy of the completed form, along with the most current FAQ, to the vehicle buyer. Toyota and the dealer may use this information to contact the customer when the remedy becomes available.

and the dealer may use this information to contact the customer when the remedy becomes available.

Keep the completed form on file at the dealership and send a copy to quality_compliance@toyota .com. In the subject line of the email state “Disclosure Form K0K/K1K” and include the VIN.

.com. In the subject line of the email state “Disclosure Form K0K/K1K” and include the VIN.

NOTE: Dealers can identify if any of their new and used inventory has any open campaigns in the Vehicle Inventory Summary available in Dealer Daily (https://dealerdaily.toyota.com/). The Vehicle Inventory Summary may take up to 4 hours to populate information for newly launched campaigns.

Toyota Certified Used Vehicle (TCUV)

Certified Used Vehicle (TCUV)

The TCUV policy prohibits the certification of any vehicle with an outstanding Safety Recall, Special Service Campaign, or Limited Service Campaign. Thus, no affected units are to be designated, sold, or delivered as a TCUV until all applicable Safety Recalls, Special Service Campaigns, and Limited Service Campaigns have been completed on that vehicle.

Toyota Rent-A-Car (TRAC) & Service Loaners

Rent-A-Car (TRAC) & Service Loaners

Toyota requests that dealers remove all TRAC and Service Loaner vehicles from service that are covered by a Safety Recall unless the defect has been remedied.

requests that dealers remove all TRAC and Service Loaner vehicles from service that are covered by a Safety Recall unless the defect has been remedied.

Customer Handling, Parts Ordering, and Remedy Procedures

Customer Contacts

Customers who receive the owner letter may contact your dealership with questions regarding the letter and/or the Safety Recall. Please welcome them to your dealership and answer any questions that they may have. A Q&A is provided to assure a consistent message is communicated.

Customers with additional questions or concerns are asked to please contact the Toyota Customer Experience Center (1-888-270-9371) – Monday through Friday, 7:00 am to 7:00 pm, Saturday 7:00 am to 4:30 pm Central Time.

Customer Experience Center (1-888-270-9371) – Monday through Friday, 7:00 am to 7:00 pm, Saturday 7:00 am to 4:30 pm Central Time.

Media Contacts

It is imperative that all media contacts (local and national) receive a consistent message. In this regard, all media contacts must be directed to Tania Saldana (859) 815-9968 in Toyota Corporate Communications.

Corporate Communications.

Please do not provide this number to customers. Please provide this contact only to media.

Parts Ordering Process – Non SET and GST Parts Ordering Process

It is possible that parts for this campaign are either required to be ordered in Campaign Part Order Request (CPOR) on Service Lane, or have been placed on Manual Allocation Control (MAC) due to potential limited part availability. Please check the CPOR/MAC report on Dealer Daily for the most up-to-date parts ordering information.

All Safety Recall, Service Campaign (SSC/LSC) parts are eligible for the Monthly Parts Return Program. Please refer to PANT Bulletin 2011-087 for campaign parts that are currently returnable under the Monthly Parts Return Program and for additional details.

| Description | Quantity | Part Number |

| CONVERTER KIT, HYBRID VEHICLE | 1 | 04009-08152 |

| SEAL PACKING | (See Sublet) | 08826-00100 |

| THERMAL GREASE | 2 | 08887-02809 |

Technician Training Requirements

The repair quality of covered vehicles is extremely important to Toyota . All dealership technicians performing this repair are required to successfully complete the most current version of the E-Learning course “Safety Recall and Service Campaign Essentials”. To ensure that all vehicles have the repair performed correctly; technicians performing this repair are required to currently hold at least one of the following certification levels:

. All dealership technicians performing this repair are required to successfully complete the most current version of the E-Learning course “Safety Recall and Service Campaign Essentials”. To ensure that all vehicles have the repair performed correctly; technicians performing this repair are required to currently hold at least one of the following certification levels:

- Expert Technician (Hybrid)

- Master Technician

- Master Diagnostic Technician

Always check which technicians can perform the repair by logging on to https://www.uotdealerreports.com. It is the dealership’s responsibility to select technicians with the above certification level or greater to perform this repair. Carefully review your resources, the technician skill level, and ability before assigning technicians to this repair. It is important to consider technician days off and vacation schedules to ensure there are properly trained technicians available to perform this repair at all times.

TRAINING VIDEO REQUIRED:

If a replacement of the Hybrid Vehicle Converter is required, it will be necessary for each technician to compete watching a training video that will detail some key points of this replacement.

Remedy Procedures

Refer to TIS for Technical Instructions on repair. Conduct all non-completed Safety Recalls and Service Campaigns on the vehicle during the time of appointment.

Campaign Special Service Tools

The following tools will be provided to each dealership for this campaign:

| Desktop Anti-Static Mat Set | Inverter Separator Tool | Squeegee |

Repair Quality Confirmation

The repair quality of covered vehicles is extremely important to Toyota . To help ensure that all vehicles have the repair performed correctly, please designate at least one associate (someone other than the individual who performed the repair) to verify the repair quality of every vehicle prior to customer delivery.

. To help ensure that all vehicles have the repair performed correctly, please designate at least one associate (someone other than the individual who performed the repair) to verify the repair quality of every vehicle prior to customer delivery.

Parts Recovery Procedures

All parts replaced as part of this Safety Recall must be turned over to the parts department until appropriate disposition is determined. The parts department must retain these parts until notification via the Parts Recovery System (PRS) is received indicating whether to ship or scrap the parts. These parts are utilized by various departments for defect analysis, quality control analysis, product evaluation, as well as other purposes.

To help minimize dealer storage challenges, Toyota recommends that dealers:

recommends that dealers:

- File the campaign claim accurately and promptly. The time a dealer is required to hold parts is based on when the campaign claim is paid by Toyota

.

. - Monitor the Warranty Parts Recovery Notifications and Part Scrap Report regularly.

Refer to Warranty Policies 9.3 and 9.6 for additional details.

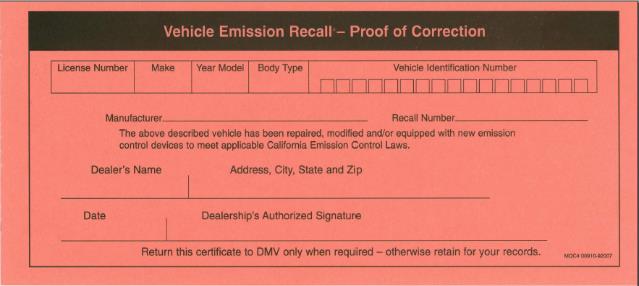

Vehicles Emission Recall Proof of Correction Form (California only)

As this Safety Recall includes emission related parts, California dealers are requested to fill out the Vehicle Emissions Recall – Proof of Correction form after repairs have been completed. The vehicle owner may require this form for vehicle registration renewal. It is important to note that the forms are an official state document and blank forms must be secured to prevent misuse. Booklets can be ordered from the MDC (material number 00410-92007).

Please complete the form and provide it to the owner. The first non-completed VINs will be submitted to the California state DMV by March 31, 2020. If the vehicle owner’s warranty claim will not be processed and paid prior to this date, please be sure to complete a form and provide it to a California owner.

Warranty Reimbursement Procedures

Warranty Reimbursement Procedure

| Op Code | Description | Flat Rate Hours |

| K0K001 | Replace DC-DC Converter ONLY | 3.4 hrs/vehicle |

| K0K002 | Serial Number Inspection ONLY | 0.3 hrs/vehicle |

| K0K003 | Serial Number Inspection +

Replace DC-DC Converter | 3.6 hrs/vehicle |

- The flat rate times include 0.1 hours for administrative cost per unit for the dealership.

- Dealers may claim the cost of 08826-00100 – (Toyota

Genuine Seal Packing 1282B, Three Bond 1282B or equivalent) under Op Code K0K001 and K0K003 at a maximum rate of $25 as sublet type “ZZ”. Please note, the entire tube of seal packing is not necessary for one repair.

Genuine Seal Packing 1282B, Three Bond 1282B or equivalent) under Op Code K0K001 and K0K003 at a maximum rate of $25 as sublet type “ZZ”. Please note, the entire tube of seal packing is not necessary for one repair. - Dealers may claim the cost of Super Long Life Coolant (1.6L per vehicle – Undiluted) under Op Code K0K002 and K0K003 at a maximum rate of $8.50 as sublet type “OF”.

- A loaner vehicle or alternative transportation through the Toyota

Rent-A-Car (TRAC) can be claimed up to a maximum of 50 days as a sublet type “RT” under Op Codes K0K001, K0K002 or K0K003.

Rent-A-Car (TRAC) can be claimed up to a maximum of 50 days as a sublet type “RT” under Op Codes K0K001, K0K002 or K0K003.

- For rentals that exceed the maximum number of allowable days and/or dollars per day, refer to the Toyota

Transportation Assistance Policy (TTAP) for DSPM authorization requirements.

Transportation Assistance Policy (TTAP) for DSPM authorization requirements. - Rental invoice MUST be attached to all rental claims. These claims may be subject to debit if rental invoice is not attached.

- For rentals that exceed the maximum number of allowable days and/or dollars per day, refer to the Toyota

- Towing can be claimed under Op Codes K0K001, K0K002 or K0K003 for a maximum of $250 as sublet type “TW” in the event the customer requests vehicle pickup.

Claim Filing Accuracy and Correction Requests

It is the dealer’s responsibility to file claims correctly for this Safety Recall. This claim filing information is used by Toyota for various government reporting activities; therefore, claim filing accuracy is crucial. If it has been identified that a claim has been filed using an incorrect Op Code or a claim has been filed for an incorrect VIN, refer to Warranty Procedure Bulletin PRO17-03 to correct the claim.

for various government reporting activities; therefore, claim filing accuracy is crucial. If it has been identified that a claim has been filed using an incorrect Op Code or a claim has been filed for an incorrect VIN, refer to Warranty Procedure Bulletin PRO17-03 to correct the claim.

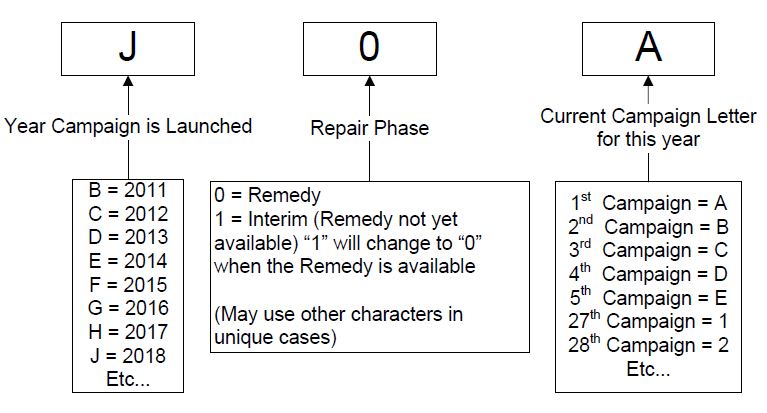

Campaign Designation / Phase Decoder

Please review this entire package with your Service and Parts staff to familiarize them with the proper step-by step procedures required to implement this Safety Recall.

Thank you for your cooperation.

TOYOTA MOTOR SALES, U.S.A., INC.

MOTOR SALES, U.S.A., INC.

SAFETY RECALL K0K (Remedy Notice)

Certain 2018-2019 Model Year Prius C Vehicles

Potential Loss of Motive Power While Driving

NHTSARecall No. 19V-491

Frequently Asked Questions

Original Publication Date: August 14, 2019

| Q1: | What is the condition? | ||||||||||||

| A1: | Due to a manufacturing issue, a component may stop performing its function of converting power from the hybrid vehicle battery for use by certain vehicle systems. If this occurs, warning lights will illuminate, audible chimes will sound, and messages will be displayed on the instrument panel. If the vehicle continues to be operated, it could lose motive power. Loss of motive power while driving at higher speeds could increase the risk of a crash.

| ||||||||||||

| Q2: | Are there any symptoms/warnings before the condition appears in vehicle? | ||||||||||||

| A2:

| No. However, if the condition occurs, warning lights for the hybrid system will illuminate, audible chimes will sound, and messages will appear on the instrument panel.

| ||||||||||||

| Q3: | What is Toyota going to do? going to do? | ||||||||||||

| A3: | Toyota is currently preparing the remedy for this condition. When the remedy becomes available, all known owners of the subject vehicles will be notified by first class mail to return their vehicles to an authorized Toyota is currently preparing the remedy for this condition. When the remedy becomes available, all known owners of the subject vehicles will be notified by first class mail to return their vehicles to an authorized Toyota dealer. Based on the vehicle identification number or an inspection, any authorized Toyota dealer. Based on the vehicle identification number or an inspection, any authorized Toyota dealer will replace the affected DC-DC converter with a new one, if necessary, FREE OF CHARGE. dealer will replace the affected DC-DC converter with a new one, if necessary, FREE OF CHARGE.

| ||||||||||||

| Q4: | Which and how many vehicles are covered by this Safety Recall? | ||||||||||||

| A4: | There are approximately 500 vehicles covered by this Safety Recall.

| ||||||||||||

| Q5: | What if I have additional questions or concerns? | ||||||||||||

| A5: | If you have additional questions or concerns, please contact the Toyota Customer Experience Center at 1-888-270-9371 Monday through Friday, 7:00 am to 7:00 pm, Saturday 7:00 am to 4:30 pm Central Time. Customer Experience Center at 1-888-270-9371 Monday through Friday, 7:00 am to 7:00 pm, Saturday 7:00 am to 4:30 pm Central Time.

| ||||||||||||

URGENT SAFETY RECALL

This is an important Safety Recall. The remedy will be performed FREE OF CHARGE to you.

This notice applies to your vehicle:

VIN ABCDEFGH987654321

IMPORTANT SAFETY RECALL (Remedy Notice)

Certain 2018-2019 Model Year Prius C Vehicles

Potential Loss of Drive Power While Driving

NHTSA Recall No. 19V-491

Dear <FirstName/LastName>:

| What Should You Do?

Please contact any authorized Toyota To find a dealer near you, visit www.toyota.com/dealers For more information on this and other Safety Recalls, including Frequently Asked Questions, visit www.toyota.com/recall. Input your full 17-digit Vehicle Identification Number (VIN) noted above to review information specific to your vehicle. If you require further assistance, you may contact the Toyota |

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act. Toyota has decided that a defect, which relates to motor vehicle safety, exists in certain 2018-2019 model year Prius C vehicles.

has decided that a defect, which relates to motor vehicle safety, exists in certain 2018-2019 model year Prius C vehicles.

You received this notice because our records, which are based primarily on state registration and title data, indicate that you are the current owner.

What is the condition?

Due to a manufacturing issue, a component may stop performing its function of converting power from the hybrid vehicle battery for use by certain vehicle systems. If this occurs, warning lights will illuminate, audible chimes will sound, and messages will be displayed on the instrument panel. If the vehicle continues to be operated, it could lose drive power. Loss of drive power could increase the risk of a crash.

What will Toyota do?

do?

Any authorized Toyota dealer will replace the affected DC-DC converter with a new one FREE OF CHARGE.

dealer will replace the affected DC-DC converter with a new one FREE OF CHARGE.

| Spanish translation on back side Traducción en español en el lado inverso |

K0K replace

| This is an important Safety Recall.

The remedy will take approximately three and a half hours. However, depending on the dealer’s work schedule, it may be necessary to make your vehicle available for a longer period of time. If the condition occurs, warning lights for the hybrid system will illuminate, audible chimes will sound, and messages will appear on the instrument panel. If the vehicle continues to be operated, it could lose drive power. If you see these warning lights or messages or hear the audible chimes, please stop your vehicle in a safe place and contact any authorized Toyota

|

What if you live in California and do not have this Safety Recall Campaign performed?

The state of California requires the completion of Safety Recalls / Service Campaigns on emission related parts prior to vehicle registration renewal. In addition, the State requires that every vehicle must pass an emission test (SMOG Check) every two years and before it is sold. Without the completion of this FREE Safety Recall Campaign, the California Air Resources Board (CARB) will not allow your vehicle to be registered. State of California Regulations require Toyota to provide the Department of Motor Vehicles with a record of all vehicles that have not had the Safety Recall Campaign completed.

to provide the Department of Motor Vehicles with a record of all vehicles that have not had the Safety Recall Campaign completed.

Your Toyota dealer will provide you with a Vehicle Emissions Recall Proof of Correction Form after the campaign has been completed. Please ensure you retain this form, because the DMV may require that you supply proof that the campaign has been completed during your vehicle registration renewal process.

dealer will provide you with a Vehicle Emissions Recall Proof of Correction Form after the campaign has been completed. Please ensure you retain this form, because the DMV may require that you supply proof that the campaign has been completed during your vehicle registration renewal process.

What if you are not the owner or operator of this vehicle?

If you are a vehicle lessor, Federal Law requires that any vehicle lessor receiving this recall notice must forward a copy of this notice to the lessee within ten days.

If you know the current owner or operator, please forward this letter to them.

If you would like to update your vehicle ownership or contact information, you may do so by registering at www.toyota.com/owners. You will need your full 17-digit Vehicle Identification Number (VIN) to input the new information.

If you believe that the dealer or Toyota has failed or is unable to remedy the defect within a reasonable time or without charge, you may submit a complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Avenue S.E., Washington, D.C. 20590, or call the toll free Vehicle Safety Hot Line at 1-888-327-4236 (TTY: 1-800-424-9153), or go to https://www.safercar.gov.

has failed or is unable to remedy the defect within a reasonable time or without charge, you may submit a complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Avenue S.E., Washington, D.C. 20590, or call the toll free Vehicle Safety Hot Line at 1-888-327-4236 (TTY: 1-800-424-9153), or go to https://www.safercar.gov.

We have sent this notice in the interest of your continued satisfaction with our products. We sincerely regret any inconvenience this condition may have caused you.

Thank you for driving a Toyota .

.

Sincerely,

Toyota Motor Sales, USA

Motor Sales, USA

6565 Headquarters Drive

Plano,TX 75024

(469) 292-4000

RETIRO DE SEGURIDAD URGENTE

Este es un Retiro de Seguridad importante. El Remedio se efectuará SIN CARGO para usted.

Este aviso aplica a su vehículo:

VIN ABCDEFGH987654321

IMPORTANTE RETIRO DE SEGURIDAD (Aviso de Remedio)

Ciertos vehículos modelo Prius C de años 2018–2019

Posible pérdida de potencia motriz al conducir

No. de retiro de NHTSA 19V-491

Estimado (nombre/apellido del cliente):

| ¿Qué Debe Hacer Usted?

Por favor, póngase en contacto con cualquier concesionario Toyota Para encontrar su concesionario más cercano, visite www.toyota.com/dealers Para más información acerca de este Retiro de Seguridad y otros, incluidas las preguntas más frecuentes, visite www.toyota.com/recall. Ingrese su Número de Identificación del Vehículo (VIN) de 17 dígitos que aparece en la parte superior para revisar la información específica a su vehículo. Si necesita más asistencia, puede comunicarse con el Centro de Experiencia del Cliente de Toyota |

Esta notificación se le envía de acuerdo con los requisitos establecidos en el Acta de Tráfico Nacional y de Seguridad de Vehículos Motorizados. Toyota ha decidido que existe un defecto relacionado con la seguridad de los vehículos motorizados en ciertos vehículos modelo Prius C de años 2018 a 2019.

ha decidido que existe un defecto relacionado con la seguridad de los vehículos motorizados en ciertos vehículos modelo Prius C de años 2018 a 2019.

Usted recibió este aviso porque nuestros registros, basados principalmente en la información de registro y titularidad estatal, indican que usted es el propietario actual.

¿Cuál es la condición?

Debido a un problema de fábrica, uno de los componentes podría dejar de realizar su función de convertir la potencia de la batería híbrida del vehículo, lo cual es necesario para el funcionamiento de algunos sistemas del vehículo. Si se produce esta condición, las luces de aviso se iluminarán, se activará una alarma sonora y se mostrarán mensajes en el panel de instrumentos. Si el vehículo continúa operándose, podría perder su potencia motriz. La pérdida de potencia motriz cuando el vehículo está en marcha a una velocidad considerable podría aumentar el riesgo de colisión.

¿Qué hará Toyota ?

?

Cualquier concesionario Toyota autorizado reemplazará el convertidor DC-DC afectado por uno nuevo SIN CARGO para usted.

autorizado reemplazará el convertidor DC-DC afectado por uno nuevo SIN CARGO para usted.

| English version on front side Versión en inglés en el frente |

K0K replace

| Este es un Retiro de Seguridad importante.

El remedio tomará aproximadamente tres horas y media. Sin embargo, dependiendo del horario de trabajo del concesionario, es posible que necesiten su vehículo por más tiempo. Si se produce esta condición, las luces de aviso del sistema híbrido se iluminarán, se activará una alarma sonora y aparecerán mensajes en el panel de instrumentos. Si el vehículo continúa operándose, podría perder su potencia motriz. Si ve dichas luces de aviso o mensajes o escucha la alarma sonora, detenga su vehículo en un lugar seguro y contacte con cualquier concesionario Toyota

|

¿Qué sucede si usted vive en California y no lleva su vehículo a un concesionario para que se implemente esta campaña de retiro de seguridad?

El estado de California exige la ejecución de las Campañas de Retiro de Seguridad/Servicio para las piezas relacionadas con la emisión de gases antes de poder renovar la matrícula del vehículo. Además, este estado requiere que cada vehículo pase una prueba de emisiones (SMOG Check) cada dos años y antes de la venta. Si no lleva a cabo esta campaña de Retiro de Seguridad GRATUITA, la Junta de Recursos del Aire de California (California Air Resources Board, CARB) no permitirá que su vehículo esté matriculado. Las regulaciones del estado de California exigen que Toyota le proporcione al Departamento de Vehículos Motorizados (DMV) un registro de todos los vehículos que no hayan completado la campaña de retiro de seguridad.

le proporcione al Departamento de Vehículos Motorizados (DMV) un registro de todos los vehículos que no hayan completado la campaña de retiro de seguridad.

Luego de que se haya completado esta campaña, su concesionario Toyota le entregará un formulario de prueba como comprobante de que ha realizado esta reparación de las emisiones del vehículo. Asegúrese de conservar este formulario, puesto que el DMV puede requerir que presente un comprobante de realización de esta campaña durante el proceso de renovación de la matrícula de su vehículo.

le entregará un formulario de prueba como comprobante de que ha realizado esta reparación de las emisiones del vehículo. Asegúrese de conservar este formulario, puesto que el DMV puede requerir que presente un comprobante de realización de esta campaña durante el proceso de renovación de la matrícula de su vehículo.

¿Qué sucede si usted no es el propietario o usuario de este vehículo?

Si usted es arrendador del vehículo, la Ley Federal exige que toda persona que arriende vehículos y reciba este aviso de retiro de seguridad envíe una copia del mismo al arrendatario dentro de los diez días.

Si conoce al propietario o usuario actual del vehículo, por favor, reenvíeles esta carta.

Si desea actualizar la información de propiedad de su vehículo o de contacto, puede hacerlo registrándose en www.toyota.com/owners. Necesitará su Número de Identificación del Vehículo (VIN) de 17 dígitos para ingresar la nueva información.

Si considera que el concesionario o Toyota no han logrado o no pueden solucionar el defecto dentro de un plazo razonable o sin costo para usted, puede presentar una queja al Administrador, a la National Highway Traffic Safety Administration [Administración Nacional de Seguridad Vial en Autopistas], 1200 New Jersey Avenue S.E., Washington, D.C. 20590, o llame sin costo a la línea directa de Seguridad Automotor al 1-888-327-4236 (TTY: 1-800-424-9153), o visite https://www.safercar.gov.

no han logrado o no pueden solucionar el defecto dentro de un plazo razonable o sin costo para usted, puede presentar una queja al Administrador, a la National Highway Traffic Safety Administration [Administración Nacional de Seguridad Vial en Autopistas], 1200 New Jersey Avenue S.E., Washington, D.C. 20590, o llame sin costo a la línea directa de Seguridad Automotor al 1-888-327-4236 (TTY: 1-800-424-9153), o visite https://www.safercar.gov.

Hemos enviado este aviso porque estamos interesados en su constante satisfacción con nuestros productos. Lamentamos sinceramente cualquier inconveniente que esta condición le haya podido causar.

Gracias por conducir un Toyota .

.

Atentamente,

Toyota Motor Sales, USA

Motor Sales, USA

Original Publication Date: June 26th, 2019

To: All Toyota Dealer Principals, General Managers, Service Managers, and Parts Managers

Dealer Principals, General Managers, Service Managers, and Parts Managers

SAFETY RECALL K0K (Interim Notice K1K)

Certain 2018-2019 Model Year Prius C Vehicles

Potential Loss of Motive Power While Driving

| Model / Years | Production Period | Approximate Total Vehicles | Approximate Stop Sale Dealer Inventory |

| 2018 – 2019 Prius C | Early February 2018 – Early October 2018 | 500 | 8 |

| STOP! DO NOT SELL NEW VEHICLES IN DEALER INVENTORY.

Refer to Dealer Inventory Procedures section for more details. |  |

On June 26, 2019, Toyota filed a Defect Information Report (DIR) with the National Highway Traffic Safety Administration (NHTSA) informing the agency of our intent to conduct a voluntary Safety Recall on 2018 – 2019 model year Prius C vehicles.

filed a Defect Information Report (DIR) with the National Highway Traffic Safety Administration (NHTSA) informing the agency of our intent to conduct a voluntary Safety Recall on 2018 – 2019 model year Prius C vehicles.

Condition

Due to a manufacturing issue, a component may stop performing its function of converting power from the hybrid vehicle battery for use by certain vehicle systems. If this occurs, warning lights will illuminate, audible chimes will sound, and messages will be displayed on the instrument panel. If the vehicle continues to be operated, it could lose motive power. Loss of motive power while driving at higher speeds could increase the risk of a crash.

Remedy

Toyota is currently preparing the remedy. When the remedy becomes available, based on the vehicle identification number or an inspection, any authorized Toyota

is currently preparing the remedy. When the remedy becomes available, based on the vehicle identification number or an inspection, any authorized Toyota dealer will replace the affected DC-DC converter with a new one, if necessary, FREE OF CHARGE.

dealer will replace the affected DC-DC converter with a new one, if necessary, FREE OF CHARGE.

Covered Vehicles

There are approximately 500 vehicles covered by this Safety Recall. Approximately 10 vehicles involved in this Safety Recall were distributed to Puerto Rico.

Owner Letter Mailing Date

Toyota will notify owners by mid-August 2019.

will notify owners by mid-August 2019.

Toyota makes significant effort to obtain current customer name and address information from each state through industry resources when mailing owner letters. In the event your dealership receives a notice for a vehicle that was sold prior to the Safety Recall announcement, it is the dealership’s responsibility to forward the owner letter to the customer who purchased the vehicle.

makes significant effort to obtain current customer name and address information from each state through industry resources when mailing owner letters. In the event your dealership receives a notice for a vehicle that was sold prior to the Safety Recall announcement, it is the dealership’s responsibility to forward the owner letter to the customer who purchased the vehicle.

Please note that only owners of the covered vehicles will be notified. If you are contacted by an owner who has not yet received a notification, please verify eligibility by confirming through TIS prior to performing repairs. Dealers should perform the repair as outlined in the Technical Instructions found on TIS.

Dealer Inventory Procedures

New Vehicles in Dealership Inventory

There are approximately 8 vehicles in new dealer inventory as of June 25, 2019.

| Under Title 49, Section 30112 of the United States Code, a dealer cannot sell, offer for sale, or introduce or deliver for introduction in interstate commerce a new motor vehicle when it is aware that the vehicle does not comply with an applicable Federal Motor Vehicle Safety Standard or contains a defect related to motor vehicle safety. Further, 49 Code of Federal Regulations §577.13 requires us to provide the following advisory: It is a violation of Federal law for a dealer to deliver a new motor vehicle or any new or used item of motor vehicle equipment (including a tire) covered by this notification under a sale or lease until the defect or noncompliance is remedied.

Toyota |

| Vehicle Safety Recall completion should always be verified through TIS. We request your assistance to ensure involved vehicles are identified and not delivered prior to performing the remedy. | |

NOTE:

- New vehicles in dealer inventory subject to a Safety Recall must be remedied before delivery into commerce under a sale or lease. Dealer-to-dealer trades as well as vehicle sales between dealers should not be made until a vehicle is remedied.

- Dealers can identify if any of their new and used inventory has any open campaigns in the Vehicle Inventory Summary available in Dealer Daily (https://dealerdaily.toyota.com/). The Vehicle Inventory Summary may take up to 4 hours to populate information for newly launched campaigns.

Inspection Reminder Mirror Hang Tags for Covered Vehicles in New Dealer Stock

To easily recognize vehicles involved in this Safety Recall, each dealership should utilize Inspection Reminder Hang Tags. Inside the vehicle’s glove box are stickers containing the VIN. Apply one of these stickers to the hang tag and install the hang tag in the vehicle. A sample copy of the Inspection Reminder Hang Tag has been included for your reference.

| Part Number | Description | Quantity |

| 00411-140003 | Inspection Mirror Hang Tag | 25 Per Pack |

NOTE: Dealerships can order hang tags from the Material Distribution Center (MDC).

Pre-Owned Vehicles in Dealer Inventory

Toyota typically requests that dealers NOT deliver any pre-owned vehicles in dealer inventory that are covered by a Safety Recall unless the defect has been remedied. In this case, until remedy parts are available, delivery of a pre-owned vehicle is acceptable if disclosed to the customer that the vehicle is involved in this Safety Recall and that the remedy is currently being prepared by Toyota

typically requests that dealers NOT deliver any pre-owned vehicles in dealer inventory that are covered by a Safety Recall unless the defect has been remedied. In this case, until remedy parts are available, delivery of a pre-owned vehicle is acceptable if disclosed to the customer that the vehicle is involved in this Safety Recall and that the remedy is currently being prepared by Toyota .

.

Toyota expects dealers to use the attached Customer Contact and Vehicle Disclosure Form to obtain vehicle buyer information. Dealers are expected to provide a copy of the completed form, along with the most current FAQ, to the vehicle buyer. Toyota

expects dealers to use the attached Customer Contact and Vehicle Disclosure Form to obtain vehicle buyer information. Dealers are expected to provide a copy of the completed form, along with the most current FAQ, to the vehicle buyer. Toyota and the dealer may use this information to contact the customer when the remedy becomes available.

and the dealer may use this information to contact the customer when the remedy becomes available.

Keep the completed form on file at the dealership and send a copy to quality_compliance@toyota .com. In the subject line of the email, state “Disclosure Form K0K/K1K” and include the VIN.

.com. In the subject line of the email, state “Disclosure Form K0K/K1K” and include the VIN.

NOTE: Dealers can identify if any of their new and used inventory has any open campaigns in the Vehicle Inventory Summary available in Dealer Daily (https://dealerdaily.toyota.com/). The Vehicle Inventory Summary may take up to 4 hours to populate information for newly launched campaigns.

Toyota Certified Used Vehicle (TCUV)

Certified Used Vehicle (TCUV)

The TCUV policy prohibits the certification of any vehicle with an outstanding Safety Recall, Special Service Campaign, or Limited Service Campaign. Thus, no affected units are to be designated, sold, or delivered as a TCUV until all applicable Safety Recalls, Special Service Campaigns, and Limited Service Campaigns have been completed on that vehicle.

Toyota Rent-A-Car (TRAC) & Service Loaners

Rent-A-Car (TRAC) & Service Loaners

Toyota requests that dealers remove all TRAC and Service Loaner vehicles from service that are covered by a Safety Recall unless the defect has been remedied.

requests that dealers remove all TRAC and Service Loaner vehicles from service that are covered by a Safety Recall unless the defect has been remedied.

Customer Handling, Parts Ordering, and Remedy Procedures

Customer Contacts

Customers who receive the owner letter may contact your dealership with questions regarding the letter and/or the Safety Recall. Please welcome them to your dealership and answer any questions that they may have. A Q&A is provided to assure a consistent message is communicated.

Customers with additional questions or concerns are asked to please contact the Toyota Customer Experience Center (1-888-270-9371) – Monday through Friday, 7:00 am to 7:00 pm, Saturday 7:00 am to 4:30 pm Central Time.

Customer Experience Center (1-888-270-9371) – Monday through Friday, 7:00 am to 7:00 pm, Saturday 7:00 am to 4:30 pm Central Time.

Media Contacts

It is imperative that all media contacts (local and national) receive a consistent message. In this regard, all media contacts must be directed to Tania Saldana (859) 815-9968 in Toyota Corporate Communications. Please do not provide this number to customers. Please provide this contact only to media.

Corporate Communications. Please do not provide this number to customers. Please provide this contact only to media.

Warranty Reimbursement Procedures

Alternate Transportation Reimbursement Procedure

Until the remedy is available, customers who are uncomfortable driving their vehicle during the interim phase may receive alternative transportation which can be claimed for $35 per day.

NOTE:

- Toyota is currently preparing the rental opcodes and will update this document once they become available.

- For rentals that exceed the maximum number of allowable days and/or dollars per day, refer to the Toyota Transportation Assistance Policy (TTAP) for DSPM authorization requirements.

- Rental invoice MUST be attached to all rental claims. These claims may be subject to debit if rental invoice is not attached.

Campaign Designation / Phase Decoder

Please review this entire package with your Service and Parts staff to familiarize them with the proper step-bystep procedures required to implement this Safety Recall.

Thank you for your cooperation.

TOYOTA MOTOR SALES, U.S.A., INC.

MOTOR SALES, U.S.A., INC.

SAFETY RECALL K0K (Interim Notice K1K)

Certain 2018-2019 Model Year Prius C Vehicles

Potential Loss of Motive Power While Driving

Frequently Asked Questions

Original Publication Date: June 26th, 2019

| Q1: | What is the condition? | ||||||||||||

| A1: | Due to a manufacturing issue, a component may stop performing its function of converting power from the hybrid vehicle battery for use by certain vehicle systems. If this occurs, warning lights will illuminate, audible chimes will sound, and messages will be displayed on the instrument panel. If the vehicle continues to be operated, it could lose motive power. Loss of motive power while driving at higher speeds could increase the risk of a crash.

| ||||||||||||

| Q2: | Are there any symptoms/warnings before the condition appears in vehicle? | ||||||||||||

| A2:

| No. However, if the condition occurs, warning lights for the hybrid system will illuminate, audible chimes will sound, and messages will appear on the instrument panel.

| ||||||||||||

| Q3: | What is Toyota going to do? going to do? | ||||||||||||

| A3: | Toyota is currently preparing the remedy for this condition. When the remedy becomes available, all known owners of the subject vehicles will be notified by first class mail to return their vehicles to an authorized Toyota is currently preparing the remedy for this condition. When the remedy becomes available, all known owners of the subject vehicles will be notified by first class mail to return their vehicles to an authorized Toyota dealer. Based on the vehicle identification number or an inspection, any authorized Toyota dealer. Based on the vehicle identification number or an inspection, any authorized Toyota dealer will replace the affected DC-DC converter with a new one, if necessary, FREE OF CHARGE. dealer will replace the affected DC-DC converter with a new one, if necessary, FREE OF CHARGE.

| ||||||||||||

| Q4: | Which and how many vehicles are covered by this Safety Recall? | ||||||||||||

| A4: | There are approximately 500 vehicles covered by this Safety Recall.

| ||||||||||||

| Q5: | What if I have additional questions or concerns? | ||||||||||||

| A5: | If you have additional questions or concerns, please contact the Toyota Customer Experience Center at 1-888-270-9371 Monday through Friday, 7:00 am to 7:00 pm, Saturday 7:00 am to 4:30 pm Central Time. Customer Experience Center at 1-888-270-9371 Monday through Friday, 7:00 am to 7:00 pm, Saturday 7:00 am to 4:30 pm Central Time.

| ||||||||||||

SEOCONTENT-START

TECHNICAL INSTRUCTIONS

FOR

SAFETY RECALL K0K

Phase 1

(Phase 2 vehicles will be covered in a separate TI)

POTENTIAL LOSS OF MOTIVE POWER WHILE DRIVING

CERTAIN 2018-2019 PRIUS C

The repair quality of covered vehicles is extremely important to Toyota . All dealership technicians performing this recall are required to successfully complete the most current version of the E-Learning course “Safety Recall and Service Campaign Essentials”. To ensure that all vehicles have the repair performed correctly; technicians performing this recall repair are required to currently hold at least one of the following certification levels:

. All dealership technicians performing this recall are required to successfully complete the most current version of the E-Learning course “Safety Recall and Service Campaign Essentials”. To ensure that all vehicles have the repair performed correctly; technicians performing this recall repair are required to currently hold at least one of the following certification levels:

• Expert Technician (Hybrid)

• Master Technician

• Master Diagnostic Technician

It is the dealership’s responsibility to select technicians with the above certification level or greater to perform this recall repair. Carefully review your resources, the technician skill level, and ability before assigning technicians to this repair. It is important to consider technician days off and vacation schedules to ensure there are properly trained technicians available to perform this repair at all times.

2

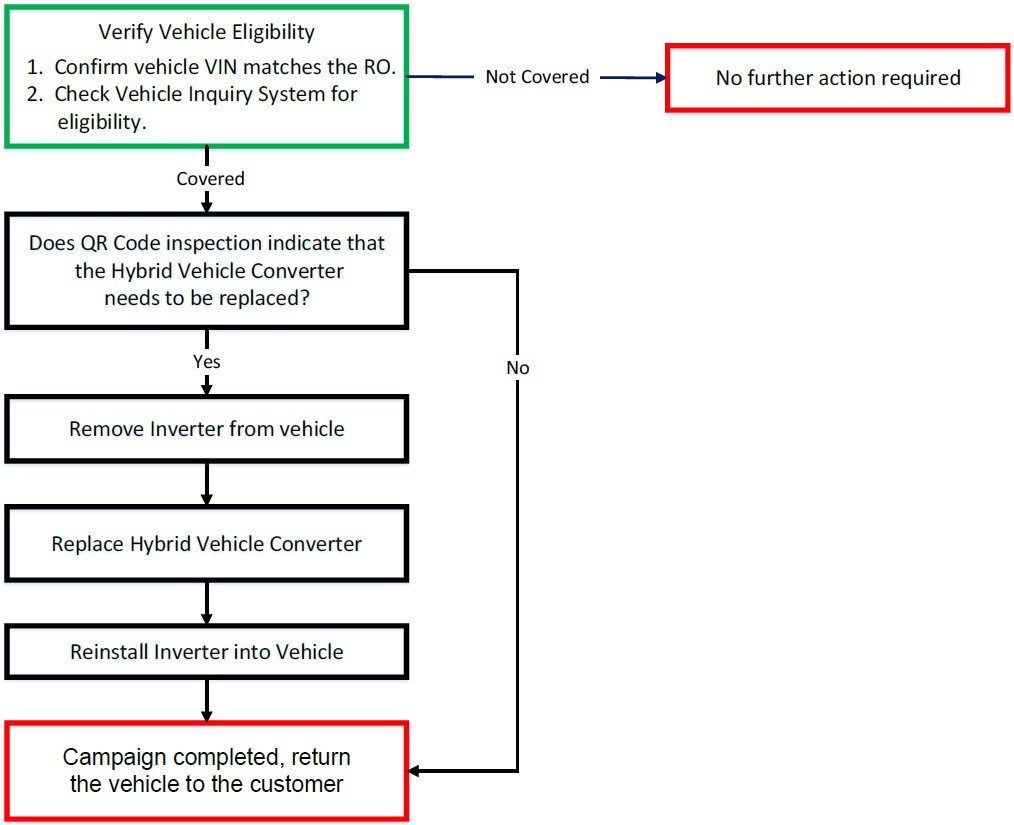

I. OPERATION FLOW CHART

Covered

Campaign completed, return

the vehicle to the customer

Verify Vehicle Eligibility

1. Confirm vehicle VIN matches the RO.

2. Check Vehicle Inquiry System for

eligibility.

..Not Covered.. No further action required

Reinstall Inverter into Vehicle

Remove Inverter from vehicle

Replace Hybrid Vehicle Converter

Is this vehicle covered in Phase 1 of the

remedy repair?

Yes

Refer to the Phase 2

Technical Instructions

..No..

II. IDENTIFICATION OF AFFECTED VEHICLES

1. CHECK VEHICLE FOR CAMPAIGN ELIGIBILITY

a. Compare the vehicles VIN to the VIN listed on the Repair Order to ensure they match.

b. Check the TIS Vehicle Inquiry System to confirm the VIN is involved in this Campaign, and

that it has not already been completed.

Note: TMNA warranty will not reimburse dealers for repairs completed on vehicles that are not

affected or were previously completed, even by another dealer.

2. CONFIRM VEHICLE IS INCLUDED IN PHASE 1

a. Using the TIS Vehicle Inquiry System, confirm that this vehicle is included in Phase 1 of this

Safety Recall. If this vehicle is included in Phase 2, refer to the separate instructions for

Phase 2.

3

III. PREPARATION

A. PARTS

Part Number Part Description Quantity

04009-08152

CONVERTER KIT, HYBRID VEHICLE *

1

*The kit above includes the following parts:

Part Number

Part Description

Quantity

04899-52011

CASE SUB-ASSY, W/CONVERTER

1

SEAL, MASKING, NO.1

1

BOLT, WASHER BASED HEAD HEXAGON

4

NUT

4

04899-47060

PLUG, INVERTER DRAIN W/SHEET, NO.1

1

PLUG, INVERTER DRAIN W/SHEET, NO.2

1

GROMMET, INVERTER UNION

2

BOLT, STUD

2 (Will not be used)

The Hybrid Vehicle Converter Kit is on MAC. See page 11 for MAC release directions.

B. TOOLS & EQUIPMENT

• Techstream

• Standard Hand Tools

• Torque Wrench

• Safety Glasses

• DVOM (CAT III rated)

• HEV Workstation

C. MATERIALS

• Toyota Super Long Life Coolant – 1.6 liters (1.6 US qts, 1.4 Imp. Qts)

Super Long Life Coolant – 1.6 liters (1.6 US qts, 1.4 Imp. Qts)

• Toyota Genuine Seal Packing 1282B, Three Bond 1282B or equivalent: 08826-00100

Genuine Seal Packing 1282B, Three Bond 1282B or equivalent: 08826-00100

• Thermal Grease: 08887-02809 (Quantity 2)

D. CAMPAIGN TOOLS

The following tools will be provided to each dealership for this campaign:

Desktop Anti-Static Mat Set

Inverter Separator Tool

Squeegee

4

IV. BACKGROUND

Due to a manufacturing issue, a component may stop performing its function of converting power from the hybrid vehicle battery for use by certain vehicle systems. If this occurs, warning lights will illuminate, audible chimes will sound, and messages will be displayed on the instrument panel. If the vehicle continues to be operated, it could lose motive power. Loss of motive power while driving at higher speeds could increase the risk of a crash.

5

V. COMPONENTS

6

7

8

VI. SAFETY PRECAUTIONS

CAUTION:

This vehicle has a hybrid control system that operates at voltages of up to 650 V. An organic electrolyte containing carbonic acid esters as its main component is used as the electrolyte for the HV battery. Be sure to follow the instructions in this manual to handle the system correctly. Failure to do so may result in serious injury or electrocution.

(a) Technicians must undergo special training to be able to service and inspect the high-voltage system.

(b) All high-voltage wire harnesses and connectors are colored orange. Do not carelessly touch these wires or components.

(c) When there is a problem with the wire harness or connector of a high-voltage circuit, repairs to the harness or connector should not be attempted. Replace damaged or malfunctioning high voltage cables or connectors.

(d) Before inspecting or servicing the high-voltage system, be sure to follow all safety measures, such as wearing insulated gloves and removing the service plug to prevent electrocution. Carry the removed service plug in your pocket to prevent other technicians from accidentally reconnecting it while you are servicing the vehicle.

NOTICE:

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

(e) After removing the service plug grip, wait 10 minutes before touching any of the high-voltage connectors and terminals.

HINT:

Waiting for at least 10 minutes is required to discharge the high-voltage capacitor inside the inverter with converter assembly.

(f) Before using insulated gloves, be sure to check them for cracks, tears and other types of damage by following the manufactures recommendations.

(g) When servicing the vehicle, do not carry metal objects like mechanical pencils or rulers that can be dropped accidentally and cause a short circuit.

(h) Before touching a bare high-voltage terminal, wear insulated gloves and use a tester to make sure that the terminal voltage is 0 V. (i) After disconnecting or exposing a high-voltage connector or terminal, insulate it immediately using insulating tape.

(j) Bolts and nuts for high-voltage terminals should be tightened firmly to the specified torque. Both insufficient and excessive torque can cause failure.

(k) Use the “CAUTION: HIGH VOLTAGE DO NOT TOUCH” sign to notify other technicians that the high-voltage system is being inspected and/or repaired.

(l)After servicing the high-voltage system and before reinstalling the service plug, check again that you have not left a part or tool inside, that the high-voltage terminals are firmly tightened, and that the connectors are correctly connected.

9

(m) When performing work involving high-voltage wires, use either a tool wrapped with vinyl insulation tape or an insulated tool.

(n) When installing hybrid control system components such as the HV battery, make sure that the polarity of all connections is correct.

CAUTION:

• Do not touch any bare cables that may have high-voltage. If a cable must be touched or if accidental contact is possible, wear insulated gloves and insulate the cable using insulating tape.

• Visually check the HV battery and the immediate area for any electrolyte leakage. Do not touch any leaked liquid because it could be organic electrolyte that contains carbonic acid esters.

• The electrolyte is flammable. Keep all ignition sources such as open flame and hot objects away from the electrolyte.

• Electrolyte leaks may cause acute poisoning if a high concentration of the vapor from the organic solvent is inhaled. In case of inhalation, move the affected person to a place with ample fresh air and let them lie quietly. Seek medical care.

• In case of skin contact with the electrolyte, wash the area thoroughly with soap and plenty of water, and seek medical care. Immediately remove any contaminated clothing. Prolonged contact with the electrolyte may cause skin irritation.

• If the electrolyte comes in contact with your eyes, call out loudly for help. Do not rub your eyes. Immediately flush them with a large amount of water for at least 15 minutes and seek medical care.

• If electrolyte is swallowed, seek medical care immediately. Do not induce vomiting, unless instructed by the doctor.

(1) Wear insulated or rubber gloves, goggles, and safety shoes.

(2) Check the HV battery and immediate area for any electrolyte leakage.

CAUTION:

Do not touch any leaked liquid because it could be the organic electrolyte that contains carbonic acid esters. If contact is unavoidable, wipe the fluid off using a cloth while wearing rubber gloves, goggles and an organic solvent mask. Do not leave electrolyte-contaminated cloths unattended. Place contaminated cloths in an appropriate airtight container and dispose of them according to local regulations.

(3) Do not touch any bare cables that could be high voltage cables. If a cable must be touched or if accidental contact is possible, follow the following instructions: 1) wear insulated gloves and goggles, 2) measure the voltage between the cable and body ground using an electrical tester, and 3) insulate the cable using insulating tape.

(4) If damage to any of the high-voltage components and cables is suspected, cut the high-voltage circuit using the procedure below.

CAUTION:

Do not touch any bare cables that may have high-voltage. If a cable must be touched or if accidental contact is possible, wear insulated gloves and insulate the cable using insulating tape.

CAUTION: • Before returning the HV battery, make sure to perform recovery inspection. • Before returning the hybrid vehicle supply stack sub-assembly, make sure to perform recovery inspection. • Accidents such as electric shock may result if the HV battery or a hybrid vehicle supply stack sub-assembly is disposed of improperly or abandoned. Therefore, make sure to return all HV batteries or hybrid vehicle supply stack assemblies through an authorized collection agent. • To reduce the risk of fire, the HV battery or hybrid vehicle supply stack assembly must not be stored in an area where it will be exposed to fire or high temperatures.

10

VII. REQUIRED VIDEO E-MODULE

Before the Hybrid Vehicle Converter replacement can begin, it is required that each technician watch a video that details some key points of repair process. Completion of the video is also necessary to receive the parts kit to perform the repair.

When you select the link below, you will need to log into the Learning Center to view the video. If you have not logged into this website before, try the following login:

User Name: (your SPIN number)

Password: (your dealer code)

If you have problems logging into the Learning Center System, please contact the following:

• TMNA Dealer: 877-353-2459

• GST Dealer: 800-933-3416

• SET Dealer: 800-982-6057

The following video will demonstrate some of the key points of this repair. It is not intended to be step-by-step directions. The Repair Manual will provide the actual directions for disassembly and reassembly of the inverter. When performing this repair, pay attention to these key points discussed in this video:

REQUIRED VIDEO: Toyota Safety Recall K0K Video

Safety Recall K0K Video

Credit for the video will automatically be given once you

reach the end of the video.

Be sure to watch the video before ordering the parts, as the parts will not be released until proof of video completion is received

Note: Watching the video is only required ONCE for each technician that will perform this repair. This video is not necessary for any Certification requirements.

11

VIII. PARTS ORDERING

Once the technician has completed watching the required Toyota Safety Recall K0K Video, it will be necessary for the Parts Department to send an email to get the Manual Allocation Control (MAC) released on the Hybrid Vehicle Converter Kit (04009-08152). Please send an email to the appropriate address below:

Safety Recall K0K Video, it will be necessary for the Parts Department to send an email to get the Manual Allocation Control (MAC) released on the Hybrid Vehicle Converter Kit (04009-08152). Please send an email to the appropriate address below:

TMNA dealers: Quality_Compliance@Toyota .com

.com

GST dealers: gstpartssupport@gstoyota.com

SET dealers: setpartstechnical@jmfamily.com

Email subject: K0K Release

Email Contents:

• 04009-08152

• Dealer Code

• VIN #

• Order reference # (TMNA & SET only)

• Name of Technician performing the repair (we will verify completion of the Recall Video)

IX. REMOVE INVERTER FROM VEHICLE

1. REMOVE INVERTER ASSEMBLY

a. Use the following Repair Manual link to remove the inverter from the vehicle.

HYBRID / BATTERY CONTROL: INVERTER WITH CONVERTER: REMOVAL; RM100000000U476

X. DISASSEMBLE HYBRID VEHICLE CONVERTER

1. DISASSEMBLE HYBRID VEHICLE CONVERTER

a. Use the following Repair Manual link to disassemble the inverter assembly.

HYBRID / BATTERY CONTROL: ELECTRIC VEHICLE CONVERTER: DISASSEMBLY; RM100000000U47Q

Note: Disassembly of the inverter assembly is necessary to separate the Hybrid Vehicle Converter. Follow the Repair Manual link to reference the necessary instructions, but please refer to the TIPS listed below to insure these key points are completed correctly during disassembly.

Video: Remove Inverter Case

12

DISASSEMBLY TIPS FOR MG-ECU

DO NOT disconnect the flat cable of the MG-ECU (the upper side with the PEN sheet) since it may be broken. Make sure to disconnect the IPM side (the lower side).

• The white resin connector of the flat cable is engaged very firmly, and pulling it lightly is not enough to disconnect the white resin connector even if the lock claws are disengaged. Make sure to pull the white resin connector straight up strongly after disengaging the lock claws.

• DO NOT pull up the white resin connector without releasing the lock claws.

• DO NOT jiggle and apply force to the white resin connector when pulling it up since the lock claws of the white resin connector may be broken.

• DO NOT touch or apply force to the electronic components of the circuit board when disconnecting the white resin connector.

• DO NOT pull the harness.

• DO NOT use tools.

Video: Disassembly Tips for MG-ECU

13

DISASSEMBLY TIPS FOR IPM

The connection between the power module intelligent transistor (IPM transistor) and the hybrid vehicle converter are attached to each other with thermal grease. This grease will make it difficult to separate the two components. Make sure to follow the instructions below to avoid breakage of the IPM transistor.

• Double-check that the 4 bolts of the IPM transistor are removed.

Place a piece of shop cloth for protection and insert 2 screwdrivers wrapped in protective tape into the positions below.

Screwdriver A: Between IPM transistor and the groove of the hybrid vehicle converter

Screwdriver B: Between the notch of IPM transistor (on the extension line from the left end

of the wire harness hole) and flat surface of the hybrid vehicle converter

(Some IPM transistors have a notch and the others do not.)

• DO NOT pry with screwdrivers as the IPM transistor may be broken. Make sure to rotate the screwdrivers to release the connection.

• DO NOT insert the screwdrivers into the positions other than instructed as the IPM transistor may be broken.

Video: IPM Disassembly Tips

14

I. REASSEMBLY OF ELECTRIC VEHICLE CONVERTER

1. REASSEMBLE THE ELECTRIC VEHICLE CONVERTER

b. Use the following Repair Manual link to reassemble the Electric Vehicle Converter.

HYBRID / BATTERY CONTROL: ELECTRIC VEHICLE CONVERTER: REASSEMBLY;

RM100000000U47R

Note: Reassembly of the Electric Vehicle Converter, IPM, and inverter are covered in the Repair Manual. However, please refer to the key points listed below in the TIPS.

IPM CLEANING TIPS

1. PREPARE THE STAND FOR THE IPM

a. Install the 4 bolts and 4 nuts included in the Campaign Tool kit to the IPM transistor so that the nut is on the circuit board side.

Direction: Insert the bolt from underneath when the circuit board is facing upward

b. Place the IPM transistor, upside down, on the anti-static mat as shown in the illustration.

Note: The anti-static mat has been supplied to each dealership for this campaign.

2. CLEAN THE THERMAL GREASE FROM THE IPM

a. Using a shop cloth saturated with a non-residue solvent, wipe the thermal grease from the IPM.

Note: It is not needed to remove the thermal grease and seal packing remaining on the ORIGINAL hybrid vehicle converter as it will be replaced.

15

CASE CLEANING TIPS

REMOVE SEAL PACKING FROM INVERTER CASE

Using a clean scraper, remove any seal packing which is uneven, has peeled off or seeped out from around the contact surface and bolt holes to reach the removal level shown below.

Video: Case Cleaning Tips

Seal Packing Removal Requirements:

Location

Removal level

Sealing surface

Remove any uneven seal packing

NOT required to remove thin seal packing on the

flat surface

Holes

Remove any uneven seal packing

NOT required to remove thin seal packing

• DO NOT drop any removed seal packing into the inverter case with condenser.

• DO NOT bend the bus-bars.

• If it feels smooth when you touch the surface, the seal packing is thin enough and it does not affect the sealing performance. There is no need to remove further.

• The thin seal packing inside the bolt holes can remain.

• It is unnecessary to take much time to remove completely. Reference the sample images of the removal level to remove the seal packing.

16

INSTALLATION HOLE CLEANING TIPS

3. CLEAN INVERTER CASE INSTALLATION HOLES

a. Remove the previously installed protective tape from the No. 1 and No. 2 inverter drain plugs.

b. Apply protective tape to the installation holes of the No. 1 and No. 2 inverter drain plugs from the inside of the inverter case.

c. Using a scraper, remove any adhesive which is uneven or has seeped out from the sealing surfaces of the drain plugs.

d. Remove the tape inside the inverter when cleaning is completed.

Adhesive Removal Requirements:

Sealing surface

Removal

Remove any uneven adhesive

NOT necessary to remove thin adhesive

17

APPLY THERMAL GREASE TIP

INSTALL THE MASKING SEAL AND APPLY THERMAL GREASE

a. Using the masking seal provided in the Hybrid Vehicle Converter Kit (04009-08152), apply it to the NEW Hybrid Vehicle Converter.

b. Apply 14 lines of thermal grease (part no. 08887-02809) between the markings of the masking seal as shown in the illustration. It will take about 1.5 tubes of thermal grease to complete the 14 lines.

Make sure to apply the Thermal Grease 6mm high

and 2mm wide so that it will spread properly.

Video: Apply Thermal Grease

18

SPREAD THERMAL GREASE TIP

SPREAD THE THERMAL GREASE

a. Using the squeegee provided with the campaign tool kit, slowly spread the thermal grease in the direction shown in the diagram below.

• Start applying the thermal grease with the angle of squeegee set at 45°, and gradually tilt while moving the squeegee so that the thermal grease can be applied entirely.

• Move squeegee slowly (approx. 20 seconds one way) as the viscosity of the thermal grease is high.

• DO NOT let the thermal grease adhere to bus-bars. If any thermal grease is adhered, remove it with a clean piece of shop cloth.

• Before performing the work, check that the thermal grease contacting area of the squeegee is not damaged.

• Apply the thermal grease smoothly and evenly to ensure proper heat transfer.

b. Next, move the squeegee in the opposite direction to fill in any voids that may have occurred in the first application.

c. Repeat steps a. through b. until the thermal grease is smooth and even.

19

CHECK THERMAL GREASE APPLICATION

Check the application using the following images to ensure the thermal grease is applied thoroughly.

OK

NO holes and complete coverage (Uneven surface is acceptable)

Remove the masking seal and install the IPM transistor immediately

NG

Holes

Move on to grease application correction

(Go to the next page)

Foreign matter

20

REPAIR THERMAL GREASE

If needed, the following procedures can be used to repair the thermal grease application.

Remove any foreign matter found on the thermal grease using a clean tube of thermal grease.

Collect the thermal grease remaining on the squeegee or around the masking seal using a clean tube of thermal grease.

Apply the thermal grease collected to the areas with a shortage as smooth as possible.

Use the squeegee as before to smooth the thermal grease.

After smoothing the thermal grease, remove the masking seal and install the IPM transistor to the hybrid vehicle converter immediately.

21

APPLICATION OF SEAL PACKING TIP

Apply seal packing 128B in a continuous line to the inverter case at the locations shown in the diagram below. The bead should be 2.0 to 3.0 mm in diameter. Be sure the keep the seal packing off the coolant pipes.

Video: Application of Seal Packing

22

CASE ASSEMBLY TIP

a. Assemble the inverter case with the NEW Hybrid Vehicle Converter

• Confirm the bus-bars of the hybrid vehicle converter are on the outside.

• Be sure to align the guide pins.

Confirm that the bus-bars do not overlap the white resin parts of the inverter terminals.

a. Push the inverter case with condenser from the top to compress the seal packing on the sealing surface.

DO NOT push excessively hard, for example pressing with your full body weight. Excessive force may cause deformation of the hybrid converter bottom surface.

23

FINAL ASSEMBLY TIPS

Check the 11 bolt holes of the inverter case for any seal packing that may have seeped into the holes. If any seal packing is found in any hole, remove it with a screwdriver.

b. Install the 11 bolts to spread the seal packing.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

NOTE:

Temporarily tighten the bolts with 5.0 N・・m to spread the seal packing applied.

a) Fully tighten the 11 bolts.

Torque: 9.2 N*m (94 kgf*cm, 81 in.*lbf)

24

◄ VERIFY REPAIR QUALITY ►

Confirm the following points before returning the vehicle to the customer.

• Confirm that the 12v battery is charging when the vehicle is in the READY mode.

• Confirm inverter coolant level is correct and no leaks are present.

If you have any questions regarding this update, please contact your regional representative.

10. APPENDIX

A. PARTS DISPOSAL

As required by Federal Regulations, please make sure all recalled parts (original parts)

removed from the vehicle are disposed of in a manner in which they will not be reused,

unless requested for parts recovery return.

B. CAMPAIGN DESIGNATION DECORDER

H 0 A

Year Campaign is Launched

B = 2011

C = 2012

D = 2013

E = 2014

F = 2015

G = 2016

H = 2017

Etc…

Repair Phase

1st Campaign = A

2nd Campaign = B

3rd Campaign = C

4th Campaign = D

5th Campaign = E

27th Campaign = 1

28th Campaign = 2

Etc…

Current Campaign Letter

for this year

0 = Remedy

1 = Interim (Remedy not yet

available) will change to

when the Remedy is available

(May use other characters in

unique cases)

Examples:

C1B = Launched in 2012, Interim Phase, 2nd Campaign Launched in 2012

E0A = Launched in 2014, Remedy Phase, 1st Campaign Launched in 2014

H0A = Launched in 2017, Remedy Phase, 1st Campaign Launched in 2017.

TECHNICAL INSTRUCTIONS

FOR

SAFETY RECALL K0K

Phase 2

(Phase 1 vehicles will be covered in a separate TI)

POTENTIAL LOSS OF MOTIVE POWER WHILE DRIVING

CERTAIN 2018-2019 PRIUS C

The repair quality of covered vehicles is extremely important to Toyota. All dealership technicians performing this recall are required to successfully complete the most current version of the E-Learning course “Safety Recall and Service Campaign Essentials”. To ensure that all vehicles have the repair performed correctly; technicians performing this recall repair are required to currently hold at least one of the following certification levels:

• Expert Technician (Hybrid)

• Master Technician

• Master Diagnostic Technician

It is the dealership’s responsibility to select technicians with the above certification level or greater to perform this recall repair. Carefully review your resources, the technician skill level, and ability before assigning technicians to this repair. It is important to consider technician days off and vacation schedules to ensure there are properly trained technicians available to perform this repair at all times.

2

I. OPERATION FLOW CHART

Covered

Campaign completed, return

the vehicle to the customer

Verify Vehicle Eligibility

1. Confirm vehicle VIN matches the RO.

2. Check Vehicle Inquiry System for

eligibility.

..Not Covered.. No further action required

Reinstall Inverter into Vehicle

Remove Inverter from vehicle

Replace Hybrid Vehicle Converter

Does QR Code inspection indicate that

the Hybrid Vehicle Converter

needs to be replaced?

Yes No

Is this vehicle covered in Phase 2 of the

remedy repair?

Yes

Refer to the Phase 1

Technical Instructions

..No..

II. IDENTIFICATION OF AFFECTED VEHICLES

1. CHECK VEHICLE FOR CAMPAIGN ELIGIBILITY

a. Compare the vehicles VIN to the VIN listed on the Repair Order to ensure they match.

b. Check the TIS Vehicle Inquiry System to confirm the VIN is involved in this Campaign, and

that it has not already been completed.

Note: TMNA warranty will not reimburse dealers for repairs completed on vehicles that are not

affected or were previously completed, even by another dealer.

3

2. CONFIRM VEHICLE IS INCLUDED IN PHASE 2

a. Using the TIS Vehicle Inquiry System, confirm that this vehicle is included in Phase 2 of this Safety Recall. If this vehicle is included in Phase 1, refer to the separate instructions for Phase 1.

III. PREPARATION

A. PARTS

Part Number Part Description Quantity

04009-08152

CONVERTER KIT, HYBRID VEHICLE *

1

*The kit above includes the following parts:

Part Number

Part Description

Quantity

04899-52011

CASE SUB-ASSY, W/CONVERTER

1

SEAL, MASKING, NO.1

1

BOLT, WASHER BASED HEAD HEXAGON

4

NUT

4

04899-47060

PLUG, INVERTER DRAIN W/SHEET, NO.1

1

PLUG, INVERTER DRAIN W/SHEET, NO.2

1

GROMMET, INVERTER UNION

2

BOLT, STUD

2 (Will not be used)

The Hybrid Vehicle Converter Kit is on MAC. See page 16 for MAC release directions.

B. TOOLS & EQUIPMENT

• Techstream

• Standard Hand Tools

• Torque Wrench

• Safety Glasses