| “This site contains affiliate links for which OEMDTC may be compensated” |

January 17, 2020 NHTSA CAMPAIGN NUMBER: 20V024000

Air Bags/Seat Belt Pretensioners may not Deploy

In the event of a crash, air bags and/or seat belt pretensioners that do not deploy as intended may increase the risk of injury.

NHTSA Campaign Number: 20V024

Manufacturer Toyota Motor Engineering & Manufacturing

Motor Engineering & Manufacturing

Components AIR BAGS

Potential Number of Units Affected 2,891,976

Summary

Toyota Motor Engineering & Manufacturing (Toyota

Motor Engineering & Manufacturing (Toyota ) is recalling certain 2011-2019 Corolla, 2011-2013 Matrix, 2012-2018 Avalon, and 2013-2018 Avalon Hybrid vehicles. During certain crashes, the air bag electronic control unit (ECU) may malfunction, possibly disabling the deployment of the air bags and/or seat belt pretensioners.

) is recalling certain 2011-2019 Corolla, 2011-2013 Matrix, 2012-2018 Avalon, and 2013-2018 Avalon Hybrid vehicles. During certain crashes, the air bag electronic control unit (ECU) may malfunction, possibly disabling the deployment of the air bags and/or seat belt pretensioners.

Remedy

Toyota will notify owners, and dealers will inspect the ECU and install a noise filter between the air bag control module and its wire harness, as necessary, free of charge. Owners were notified of the safety risk beginning March 2, 2020. A second letter notifying owners of the remedy repair will be mailed between March 16, 2020 and June 27, 2020. Owners may contact Toyota

will notify owners, and dealers will inspect the ECU and install a noise filter between the air bag control module and its wire harness, as necessary, free of charge. Owners were notified of the safety risk beginning March 2, 2020. A second letter notifying owners of the remedy repair will be mailed between March 16, 2020 and June 27, 2020. Owners may contact Toyota customer service at 1-888-270-9371. Toyota

customer service at 1-888-270-9371. Toyota ’s numbers for this recall are 20TB03, 20TA03 and 20TA05.

’s numbers for this recall are 20TB03, 20TA03 and 20TA05.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Vehicle has a Recall

◄ IMPORTANT UPDATE ►

The attached Dealer Letter has been updated. Refer to the details below.

| DATE | TOPIC |

| 04/22/2020 |

|

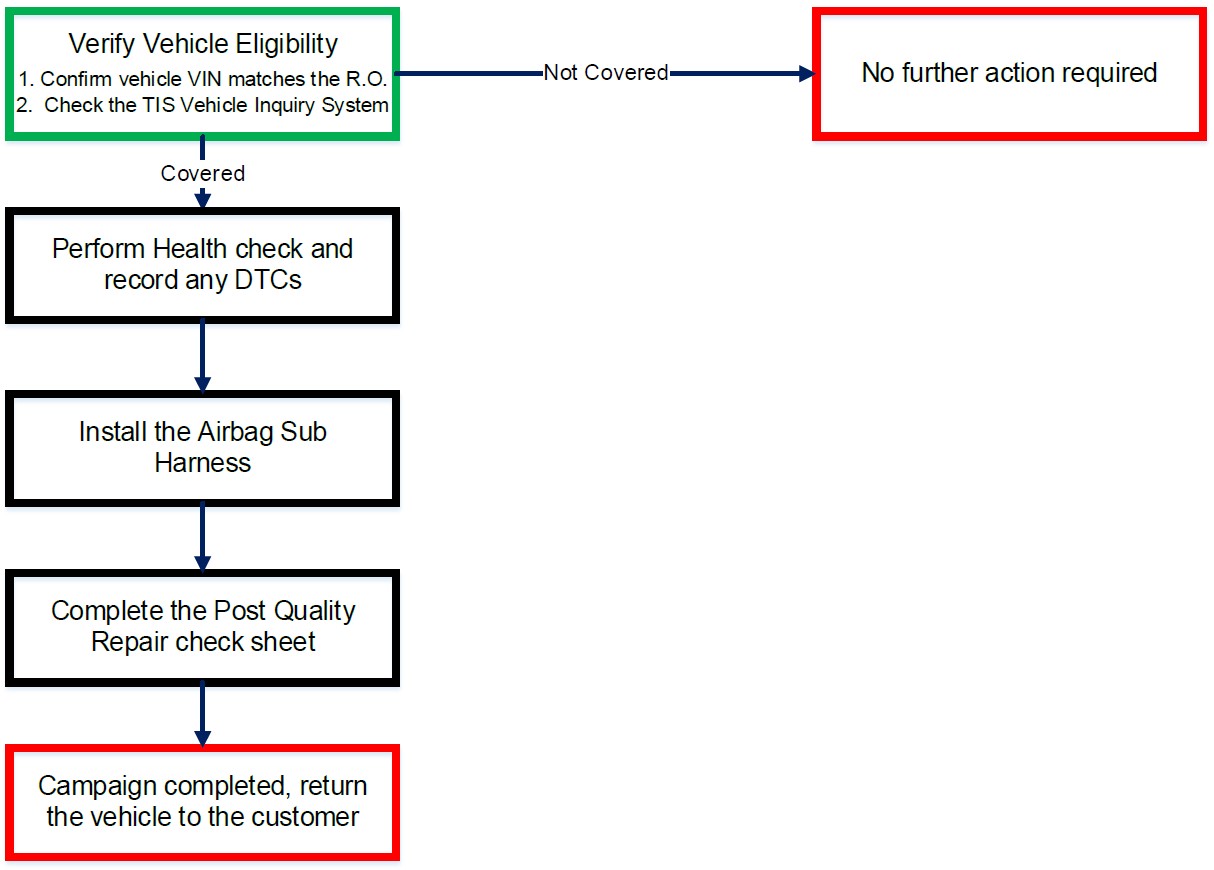

| 03/23/2020 | Added Step to Flow Chart under Warranty Reimbursement Procedure |

| 03/17/2020 | Added Toyota Customer Vehicle Offsite Storage Form Customer Vehicle Offsite Storage Form |

The most recent update in the attached Dealer Letter will be highlighted with a red box.

Please review this notification with your staff to assure that all relevant personnel have been briefed regarding this subject.

Thank you for your cooperation.

Original Publication Date: March 12, 2020

To: All Toyota Dealer Principals, General Managers, Service Managers, and Parts Managers

Dealer Principals, General Managers, Service Managers, and Parts Managers

SAFETY RECALL 20TA03 (Interim Notice 20TB03) – Remedy Notice

Certain 2011 – 2019 Model Year Corolla

Certain 2011 – 2013 Model Year Matrix

Certain 2012 – 2018 Model Year Avalon

Certain 2013 – 2018 Model Year Avalon Hybrid

Incomplete or Nondeployment of Airbags and/or Seat Belt Pretensioners May Occur

NHTSA Recall No. 20V-024

| Model / Years | Production Period | Approximate Total Vehicles | Approximate Stop Sale Dealer Inventory |

| Corolla 2011 – 2019 | Late November 2010 – Late February 2019 | 2,577,000 | 30 |

| Matrix 2011 – 2013 | Early December 2010 – Mid-June 2013 | 10,200 | 0 |

| Avalon 2012 – 2018 | Mid-May 2012 – Mid-April 2018 | 241,900 | 0 |

| Avalon HV 2013 – 2018 | Late May 2012 – Late March 2018 | 63,800 | 3 |

| STOP! DO NOT SELL NEW VEHICLES IN DEALER INVENTORY.

Refer to Dealer Inventory Procedures section for more details. |  |

On January 17, 2020, Toyota filed a Defect Information Report (DIR) with the National Highway Traffic Safety Administration (NHTSA) informing the agency of our intent to conduct a voluntary Safety Recall on certain 2011 – 2019 model year Corolla, 2011 – 2013 model year Matrix, 2012 – 2018 model year Avalon and 2013 – 2018 Avalon Hybrid vehicles.

Condition

The subject vehicles may be equipped with an electronic control unit (ECU) from a specific supplier that is designed to receive signals from crash sensors and deploy the airbags and seat belt pretensioners. The ECU may not have adequate protection against certain electrical noise that can occur in certain crashes, such as severe underride crashes. This can lead to incomplete or nondeployment of the airbags and/or seat belt pretensioners. Airbag and seat belt pretensioners that do not deploy as intended can increase the risk of injury in a crash.

Remedy

Toyota has sufficient parts to begin a phased implementation of the remedy. Any authorized Toyota

has sufficient parts to begin a phased implementation of the remedy. Any authorized Toyota dealer will, in most cases, install a noise filter between the airbag control module and its wire harness. In some cases, Toyota

dealer will, in most cases, install a noise filter between the airbag control module and its wire harness. In some cases, Toyota dealers may inspect the ECU to determine if the noise filter is necessary before installing it. The remedy will be at no cost to vehicle owners. Refer to the table below to determine the remedy status and remedy campaign designation for vehicles involved in this Safety Recall.

dealers may inspect the ECU to determine if the noise filter is necessary before installing it. The remedy will be at no cost to vehicle owners. Refer to the table below to determine the remedy status and remedy campaign designation for vehicles involved in this Safety Recall.

| Phase | Model / Years | Approximate Total Vehicles | Remedy Status | Remedy Campaign Designation |

| 1 | Corolla 2014 – 2019 | 528,000 | Remedy Available* | 20TA03 |

| 2 | Corolla 2011 – 2012 | 112,000 | Remedy Available* | 20TA05** |

| Corolla 2011 – 2013 | 616,000 | Remedy Available* | 20TA03 | |

| Matrix 2011 – 2013 | 10,200 | |||

| Avalon 2012 – 2018 | 241,900 | |||

| Avalon HV 2013 – 2018 | 63,800 | |||

| Corolla 2014 – 2019 | 1,321,000 |

*Only a portion of the 2014 – 2019 model year Corolla vehicles covered by this Safety Recall are included in the phase 1 remedy.

**Certain 2011-2012 Corolla vehicles will require an inspection of the ECU to determine if noise filter installation is necessary. These vehicles will be loaded to campaign designation 20TA05. A separate Dealer Letter and Technical Instructions will be available at the time of phase 2 remedy launch.

Covered Vehicles

There are approximately 2,892,900 vehicles covered by this Safety Recall. Approximately 50,000 vehicles involved in this Safety Recall were distributed to Puerto Rico.

Owner Letter Mailing Date

Toyota notified customers involved in phase 1 in mid-March 2020 informing them that the remedy is available. Toyota

notified customers involved in phase 1 in mid-March 2020 informing them that the remedy is available. Toyota also mailed an interim owner letter to phase 2 customers beginning early-March 2020. Phase 2 customers will be notified, beginning in late April 2020, that the remedy is now available for their vehicles. Samples of the owner notification letters have been included for your reference.

also mailed an interim owner letter to phase 2 customers beginning early-March 2020. Phase 2 customers will be notified, beginning in late April 2020, that the remedy is now available for their vehicles. Samples of the owner notification letters have been included for your reference.

Toyota makes significant effort to obtain current customer name and address information from each state through industry resources when mailing owner letters. In the event your dealership receives a notice for a vehicle that was sold prior to the Safety Recall announcement, it is the dealership’s responsibility to forward the owner letter to the customer who purchased the vehicle.

makes significant effort to obtain current customer name and address information from each state through industry resources when mailing owner letters. In the event your dealership receives a notice for a vehicle that was sold prior to the Safety Recall announcement, it is the dealership’s responsibility to forward the owner letter to the customer who purchased the vehicle.

Please note that only owners of the covered vehicles will be notified. If you are contacted by an owner who has not yet received a notification, please verify eligibility by confirming through TIS prior to performing repairs. Dealers should perform the repair as outlined in the Technical Instructions found on TIS.

Dealer Inventory Procedures

New Vehicles in Dealership Inventory

There are approximately 33 vehicles in new dealer inventory as of January 21, 2020.

| Under Title 49, Section 30112 of the United States Code, a dealer cannot sell, offer for sale, or introduce or deliver for introduction in interstate commerce a new motor vehicle when it is aware that the vehicle does not comply with an applicable Federal Motor Vehicle Safety Standard or contains a defect related to motor vehicle safety. Further, 49 Code of Federal Regulations §577.13 requires us to provide the following advisory: It is a violation of Federal law for a dealer to deliver a new motor vehicle or any new or used item of motor vehicle equipment (including a tire) covered by this notification under a sale or lease until the defect or noncompliance is remedied.

Toyota |

| Vehicle Safety Recall completion should always be verified through TIS. We request your assistance to ensure involved vehicles are identified and not delivered prior to performing the remedy. | |

NOTE:

- New vehicles in dealer inventory subject to a Safety Recall must be remedied before delivery into commerce under a sale or lease. Dealer-to-dealer trades as well as vehicle sales between dealers should not be made until a vehicle is remedied.

- Dealers can identify if any of their new and used inventory has any open campaigns in the Vehicle Inventory Summary available in Dealer Daily (Non SET and GST dealers: https://dealerdaily.toyota.com/). The Vehicle Inventory Summary may take up to 4 hours to populate information for newly launched campaigns.

Inspection Reminder Mirror Hang Tags for Covered Vehicles in New Dealer Stock

To easily recognize vehicles involved in this Safety Recall, each dealership should utilize Inspection Reminder Hang Tags. Inside the vehicle’s glove box are stickers containing the VIN. Apply one of these stickers to the hang tag and install the hang tag in the vehicle. A sample copy of the Inspection Reminder Hang Tag has been included for your reference.

Toyota Version Below

Version Below

| Part Number | Description | Quantity |

| 00411-140003 | Inspection Mirror Hang Tag | 25 Per Pack |

NOTE: Dealerships can order hang tags from the Material Distribution Center (MDC).

Pre-Owned Vehicles in Dealer Inventory

To ensure customer satisfaction, Toyota requests that dealers complete this Safety Recall on any used vehicles currently in dealer inventory that are covered by this Safety Recall prior to customer delivery. However, if the campaign cannot be completed (for example, due to remedy parts availability), delivery of a covered vehicle is acceptable if disclosed to the customer that the vehicle is involved in a Safety Recall.

requests that dealers complete this Safety Recall on any used vehicles currently in dealer inventory that are covered by this Safety Recall prior to customer delivery. However, if the campaign cannot be completed (for example, due to remedy parts availability), delivery of a covered vehicle is acceptable if disclosed to the customer that the vehicle is involved in a Safety Recall.

Toyota expects dealers to use the attached Customer Contact and Vehicle Disclosure Form to obtain vehicle buyer information. Dealers are expected to provide a copy of the completed form, along with the most current FAQ, to the vehicle buyer. Toyota

expects dealers to use the attached Customer Contact and Vehicle Disclosure Form to obtain vehicle buyer information. Dealers are expected to provide a copy of the completed form, along with the most current FAQ, to the vehicle buyer. Toyota and the dealer may use this information to contact the customer when the remedy becomes available.

and the dealer may use this information to contact the customer when the remedy becomes available.

Keep the completed form on file at the dealership and send a copy to quality_compliance@toyota .com. In the subject line of the email state “Disclosure Form 20TA03” and include the VIN.

.com. In the subject line of the email state “Disclosure Form 20TA03” and include the VIN.

NOTE: Dealers can identify if any of their new and used inventory has any open campaigns in the Vehicle Inventory Summary available in Dealer Daily (Non SET and GST dealers: https://dealerdaily.toyota.com/). The Vehicle Inventory Summary may take up to 4 hours to populate information for newly launched campaigns.

Toyota Certified Used Vehicle (TCUV)

Certified Used Vehicle (TCUV)

The TCUV policy prohibits the certification of any vehicle with an outstanding Safety Recall, Special Service Campaign, or Limited Service Campaign. Thus, no affected units are to be designated, sold, or delivered as a TCUV until all applicable Safety Recalls, Special Service Campaigns, and Limited Service Campaigns have been completed on that vehicle.

Toyota Rent-A-Car (TRAC) & Service Loaners

Rent-A-Car (TRAC) & Service Loaners

Toyota requests that dealers remove all TRAC and Service Loaner vehicles from service that are covered by a Safety Recall unless the defect has been remedied.

requests that dealers remove all TRAC and Service Loaner vehicles from service that are covered by a Safety Recall unless the defect has been remedied.

Customer Handling, Parts Ordering, and Remedy Procedures

Customer Contacts

Customers who receive the owner letter may contact your dealership with questions regarding the letter and/or the Safety Recall. Please welcome them to your dealership and answer any questions that they may have. A Q&A is provided to assure a consistent message is communicated.

Customers with additional questions or concerns are asked to please contact the Toyota Customer Experience Center (1-888-270-9371) – Monday through Friday, 7:00 am to 7:00 pm, Saturday 7:00 am to 4:30 pm Central Time.

Customer Experience Center (1-888-270-9371) – Monday through Friday, 7:00 am to 7:00 pm, Saturday 7:00 am to 4:30 pm Central Time.

Salvage Title Vehicles

Every attempt should be made to complete an open Safety Recall when circumstances permit, unless noted otherwise in the Safety Recall dealer letter.

For complete details on this policy, refer to Toyota Warranty Policy 4.17, “What Is Not Covered by The Toyota

Warranty Policy 4.17, “What Is Not Covered by The Toyota New Vehicle Limited Warranty”.

New Vehicle Limited Warranty”.

Media Contacts

It is imperative that all media contacts (local and national) receive a consistent message. In this regard, all media contacts must be directed to Tania Saldana (859) 815-9968 in Toyota Corporate Communications.

Corporate Communications.

Please do not provide this number to customers. Please provide this contact only to media.

Parts Ordering Process – Non SET and GST Parts Ordering Process

It is possible that parts for this campaign are either required to be ordered in Campaign Part Order Request (CPOR) on Service Lane, or have been placed on Manual Allocation Control (MAC) due to potential limited part availability. Please check the CPOR/MAC report on Dealer Daily for the most up-to-date parts ordering information.

All Safety Recall, Service Campaign (SSC/LSC) parts are eligible for the Monthly Parts Return Program. Please refer to PANT Bulletin 2011-087 for campaign parts that are currently returnable under the Monthly Parts Return Program and for additional details.

| Part Number | Description | Quantity |

| 04009-98112 | Airbag Harness Kit | 1 |

Technician Training Requirements

The repair quality of covered vehicles is extremely important to Toyota . All dealership technicians performing this repair are required to successfully complete the most current version of the E-Learning course “Safety Recall and Service Campaign Essentials”. To ensure that all vehicles have the repair performed correctly; technicians performing this repair are required to currently hold at least one of the following certification levels:

. All dealership technicians performing this repair are required to successfully complete the most current version of the E-Learning course “Safety Recall and Service Campaign Essentials”. To ensure that all vehicles have the repair performed correctly; technicians performing this repair are required to currently hold at least one of the following certification levels:

- Expert (Electrical or Hybrid)

- Master

- Master Diagnostic Technician

Always check which technicians can perform the repair by logging on to https://www.uotdealerreports.com. It is the dealership’s responsibility to select technicians with the above certification level or greater to perform this recall repair. Carefully review your resources, the technician skill level, and ability before assigning technicians to this repair. It is important to consider technician days off and vacation schedules to ensure there are properly trained technicians available to perform this repair at all times.

Remedy Procedures

Refer to TIS for Technical Instructions on repair. Conduct all non-completed Safety Recalls and Service Campaigns on the vehicle during the time of appointment.

Repair Quality Confirmation

The repair quality of covered vehicles is extremely important to Toyota . To help ensure that all vehicles have the repair performed correctly, please designate at least one associate (someone other than the individual who performed the repair) to verify the repair quality of every vehicle prior to customer delivery.

. To help ensure that all vehicles have the repair performed correctly, please designate at least one associate (someone other than the individual who performed the repair) to verify the repair quality of every vehicle prior to customer delivery.

Post Repair Quality Checksheet

The Technical Instructions will direct you to a website as part of the repair quality confirmation procedure. For your reference, the website and default password are listed below:

Default Password: XXXXX

Each dealer only has a single account; please ensure that the reset password is communicated to all technicians and dealer associates that will be utilizing this website.

Parts Recovery Procedures

All parts replaced as part of this Safety Recall must be turned over to the parts department until appropriate disposition is determined. The parts department must retain these parts until notification via the Parts Recovery System (PRS) is received indicating whether to ship or scrap the parts. These parts are utilized by various departments for defect analysis, quality control analysis, product evaluation, as well as other purposes.

To help minimize dealer storage challenges, Toyota recommends that dealers:

recommends that dealers:

- File the campaign claim accurately and promptly. The time a dealer is required to hold parts is based on when the campaign claim is paid by Toyota

.

. - Monitor the Warranty Parts Recovery Notifications and Part Scrap Report regularly.

Refer to Warranty Policies 9.3 and 9.6 for additional details.

Warranty Reimbursement Procedures

Loaner Vehicle or Alternative Transportation Reimbursement Procedure

For customers who request a loaner vehicle or alternative transportation through Toyota Rent-A-CAR (TRAC) during the interim phase, a loaner vehicle or alternative transportation can be claimed for $35 per day.

Rent-A-CAR (TRAC) during the interim phase, a loaner vehicle or alternative transportation can be claimed for $35 per day.

If a customer is not eligible for a loaner or alternative transportation, the customer can contact Customer Experience Center for further assistance.

| Op Code (File under designation 20TB03) | Description |

| TB03R1 | Vehicle Rental 1-30 Days |

| TB03R2 | Vehicle Rental 31-60 Days |

| TB03R3 | Vehicle Rental 61-90 Days |

NOTE:

- Rental invoice MUST be attached to all rental claims. These claims may be subject to debit if rental invoice is not attached.

- Rentals that exceed the maximum allowable daily rate will require DSPM authorization per the Toyota Transportation Assistance Policy (TTAP).

- Dealers will be allowed to file these Op Codes up to 90 days after the final phase has launched into remedy. After that time, no claims for alternative transportation reimbursement will be accepted.

Warranty Reimbursement Procedure

| Op Code | Description | Flat Rate Hours |

| 2TA031 | Install Airbag Harness Kit – Corolla & Avalon (2012MY) | 1.1 |

| 2TA032 | Install Airbag Harness Kit – Matrix (w/o rear air duct) | 1.2 |

| 2TA033 | Install Airbag Harness Kit – Matrix (w/rear air duct) | 1.4 |

| 2TA034 | Install Airbag Harness Kit – Avalon/Avalon HV (2013-2018MY) | 1.7 |

- The flat rate times include 0.1 hours for administrative cost per unit for the dealership.

Claim Filing Accuracy and Correction Requests

It is the dealer’s responsibility to file claims correctly for this Safety Recall. This claim filing information is used by Toyota for various government reporting activities; therefore, claim filing accuracy is crucial. If it has been identified that a claim has been filed using an incorrect Op Code or a claim has been filed for an incorrect VIN, refer to Warranty Procedure Bulletin PRO17-03 to correct the claim.

for various government reporting activities; therefore, claim filing accuracy is crucial. If it has been identified that a claim has been filed using an incorrect Op Code or a claim has been filed for an incorrect VIN, refer to Warranty Procedure Bulletin PRO17-03 to correct the claim.

Customer Reimbursement Reimbursement consideration instructions will be included in the owner letter.

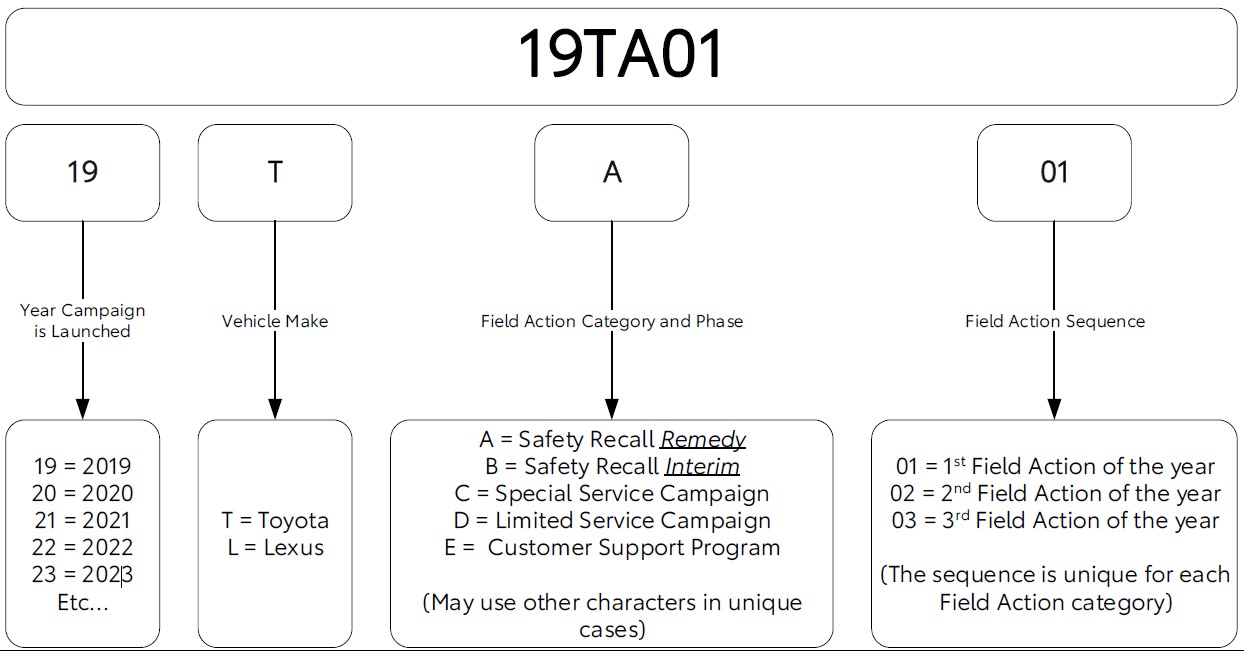

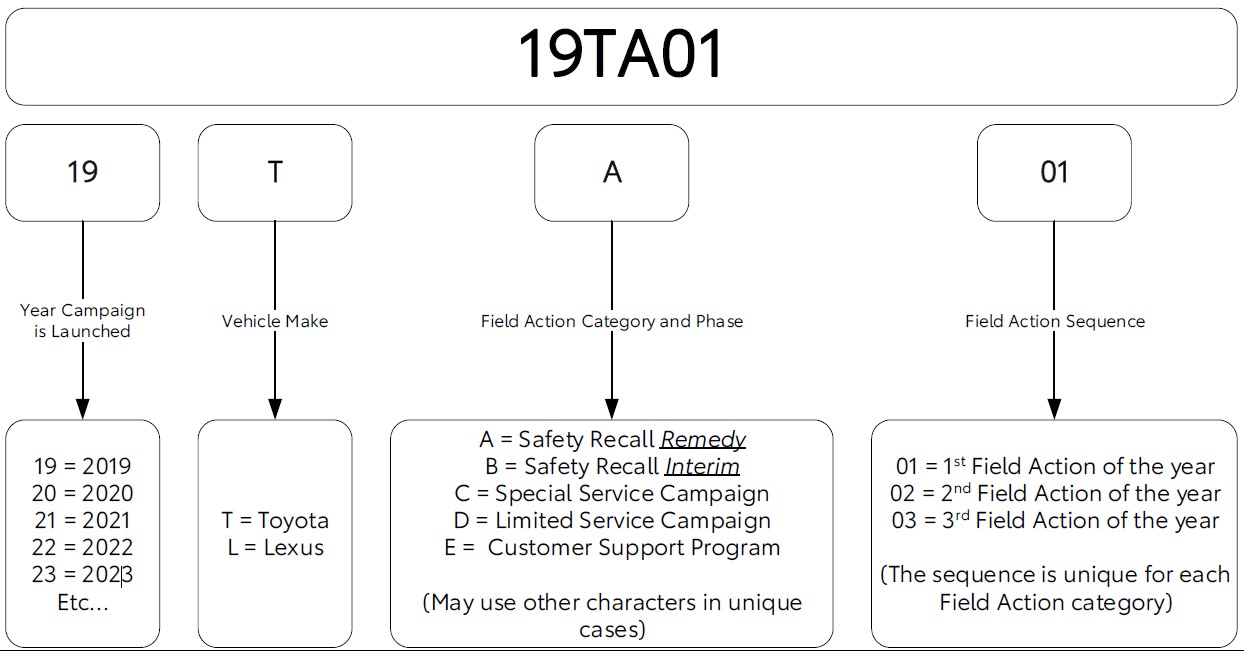

Campaign Designation / Phase Decoder

|

| Examples:

19TA01 = Launched in 2019, Toyota 20TC02 = Launched in 2020, Special Service Campaign, 2nd Special Service Campaign Launched in 2020 21TE05 = Launched in 2021, Customer Support Program, 5th Customer Support Program Launched in 2021 |

Please review this entire package with your Service and Parts staff to familiarize them with the proper step-bystep procedures required to implement this Safety Recall.

Thank you for your cooperation.

TOYOTA MOTOR SALES, U.S.A., INC.

MOTOR SALES, U.S.A., INC.

SAFETY RECALL 20TA03 (Interim Notice 20TB03) – Remedy Notice

Certain 2011 – 2019 Model Year Corolla

Certain 2011 – 2013 Model Year Matrix

Certain 2012 – 2018 Model Year Avalon

Certain 2013 – 2018 Model Year Avalon Hybrid

Incomplete or Nondeployment of Airbags and/or Seat Belt Pretensioners May Occur

NHTSA Recall No. 20V-024

Frequently Asked Questions

Original Publication Date: March 12, 2020

◄IMPORTANT UPDATE ► | |

| DATE | TOPIC |

| 04/22/2020 | Q2/A2 table has been updated for phase 2 remedy availability |

The most recent update will be highlighted with a red box.

| Q1: | What is the condition? | |||||||||||||||||||||||||||

| A1:

| The subject vehicles may be equipped with an electronic control unit (ECU) from a specific supplier that is designed to receive signals from crash sensors and deploy the airbags and seat belt pretensioners. The ECU may not have adequate protection against certain electrical noise that can occur in certain crashes, such as severe underride crashes. This can lead to incomplete or nondeployment of the airbags and/or seat belt pretensioners. Airbags and seat belt pretensioners that do not deploy as intended can increase the risk of injury in a crash.

| |||||||||||||||||||||||||||

| Q2: | What is Toyota going to do? going to do? | |||||||||||||||||||||||||||

| A2: | Toyota has sufficient parts to begin a phased implementation of the remedy. Any authorized Toyota has sufficient parts to begin a phased implementation of the remedy. Any authorized Toyota dealer will, in most cases, install a noise filter between the airbag control module and its wire harness. In some cases, Toyota dealer will, in most cases, install a noise filter between the airbag control module and its wire harness. In some cases, Toyota dealers may inspect the ECU to determine if the noise filter is necessary before installing it. The remedy will be at no cost to vehicle owners. Refer to the table below to determine the remedy status and remedy campaign designation for vehicles involved in this Safety Recall. dealers may inspect the ECU to determine if the noise filter is necessary before installing it. The remedy will be at no cost to vehicle owners. Refer to the table below to determine the remedy status and remedy campaign designation for vehicles involved in this Safety Recall.

*Only a portion of the 2014 – 2019 model year Corolla vehicles covered by this Safety Recall are included in the phase 1 remedy. Any authorized Toyota **Certain 2011-2012 Corolla vehicles will require an inspection of the ECU to determine if noise filter installation is necessary. These vehicles will be loaded to Toyota Toyota

| |||||||||||||||||||||||||||

| Q3: | Which and how many vehicles are covered by this Safety Recall? | |||||||||||||||||||||||||||

| A3: | There are approximately 2,892,900 vehicles covered by this Safety Recall.

| |||||||||||||||||||||||||||

| Q4: | What if I previously paid for repairs related to this Safety Recall? | |||||||||||||||||||||||||||

| A4: | Reimbursement consideration instructions will be provided in the owner letter.

| |||||||||||||||||||||||||||

| Q5: | How does Toyota obtain my mailing information? obtain my mailing information? | |||||||||||||||||||||||||||

| A5: | Toyota uses an industry provider who works with each state’s Department of Motor Vehicles (DMV) to receive registration or title information, based upon the DMV records. Please make sure your registration or title information is correct. uses an industry provider who works with each state’s Department of Motor Vehicles (DMV) to receive registration or title information, based upon the DMV records. Please make sure your registration or title information is correct.

| |||||||||||||||||||||||||||

| Q6: | What if I have additional questions or concerns? | |||||||||||||||||||||||||||

| A6: | If you have additional questions or concerns, please contact the Toyota Customer Experience Center at 1-888-270-9371 Monday through Friday, 7:00 am to 7:00 pm, Saturday 7:00 am to 4:30 pm Central Time. Customer Experience Center at 1-888-270-9371 Monday through Friday, 7:00 am to 7:00 pm, Saturday 7:00 am to 4:30 pm Central Time.

|

URGENT SAFETY RECALL

This is an important Safety Recall. The remedy will be performed FREE OF CHARGE to you.

This notice applies to your vehicle:

VIN ABCDEFGH987654321

IMPORTANT SAFETY RECALL (Remedy Notice)

Certain 2011–2019 Model Year Corolla

Certain 2011–2013 Model Year Matrix

Certain 2012–2018 Model Year Avalon

Certain 2013–2018 Model Year Avalon Hybrid

Incomplete or Nondeployment of Airbags and/or Seat Belt Pretensioners May Occur

NHTSA Recall No. 20V-024

Dear <FirstName/LastName>:

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act. Toyota has decided that a defect, which relates to motor vehicle safety, exists in certain 2011–2019 model year Corolla, certain 2011–2013 model year Matrix, certain 2012–2018 model year Avalon and certain 2013–2018 Avalon Hybrid vehicles.

has decided that a defect, which relates to motor vehicle safety, exists in certain 2011–2019 model year Corolla, certain 2011–2013 model year Matrix, certain 2012–2018 model year Avalon and certain 2013–2018 Avalon Hybrid vehicles.

You received this notice because our records, which are based primarily on state registration and title data, indicate that you are the current owner.

What is the condition?

The subject vehicles are equipped with an electronic control unit (ECU) from a specific supplier that is designed to receive signals from crash sensors and deploy the airbags and seat belt pretensioners. The ECU may not have adequate protection against certain electrical noise that can occur in certain crashes, such as severe underride crashes. This can lead to incomplete or nondeployment of the airbags and/or seat belt pretensioners. Airbag and seat belt pretensioners that do not deploy as intended can increase the risk of injury in a crash.

What Should You Do?

Please contact any authorized Toyota dealer to schedule an appointment to have the remedy performed as soon as possible. The remedy will require a new part to be installed. We recommend you contact your dealer to schedule an appointment in advance to confirm parts availability and minimize your inconvenience.

dealer to schedule an appointment to have the remedy performed as soon as possible. The remedy will require a new part to be installed. We recommend you contact your dealer to schedule an appointment in advance to confirm parts availability and minimize your inconvenience.

Your local Toyota dealer will be more than happy to answer any of your questions.

dealer will be more than happy to answer any of your questions.

To find a dealer near you, visit www.toyota.com/dealers.

For more information on this and other Safety Recalls, including Frequently Asked Questions, visit www.toyota.com/recall. Input your full 17-digit Vehicle Identification Number (VIN) noted above to review information specific to your vehicle.

If you require further assistance, you may contact the Toyota Customer Experience Center at 1-888-270-9371 Monday through Friday, 7:00 a.m. to 7:00 p.m., Saturday 7:00 a.m. to 4:30 p.m., Central Time.

Customer Experience Center at 1-888-270-9371 Monday through Friday, 7:00 a.m. to 7:00 p.m., Saturday 7:00 a.m. to 4:30 p.m., Central Time.

What will Toyota do?

do?

Any authorized Toyota dealer will install a noise filter between the airbag control module and its wire harness FREE OF CHARGE to you.

dealer will install a noise filter between the airbag control module and its wire harness FREE OF CHARGE to you.

This is an important Safety Recall.

The remedy will take approximately between one and one- and three-quarter hours. However, depending on the dealer’s work schedule, it may be necessary to make your vehicle available for a longer period of time.

What if you have previously paid for repairs to your vehicle for this specific condition?

If you have previously paid for repair(s) to your vehicle for this specific condition prior to receiving this letter, you may be eligible for reimbursement. For reimbursement consideration, please submit a copy of your repair details (for example: a repair order), proof-of-payment, and ownership information to Toyota ’s online, self-service portal. Log-in to your Toyota

’s online, self-service portal. Log-in to your Toyota Owners account at https:/www.toyota.com/owners/, click on the “Resources” tab, select “Safety Recalls and Service Campaigns,” and click on “Submit Reimbursement Request.”

Owners account at https:/www.toyota.com/owners/, click on the “Resources” tab, select “Safety Recalls and Service Campaigns,” and click on “Submit Reimbursement Request.”

Alternatively, if you prefer to mail or fax this information for reimbursement consideration, please use the address or fax number shown below:

Toyota Customer Experience Center – TSR

Customer Experience Center – TSR

Toyota Motor Sales, USA, Inc.

Motor Sales, USA, Inc.

c/o Toyota Motor North America, Inc.

Motor North America, Inc.

P O Box 259001 – SSC/CSP Reimbursements

Plano, Texas 75025-9001

FAX: 310-381-7756

Please refer to the attached Reimbursement Checklist for required documentation details.

What if you are not the owner or operator of this vehicle?

If you are a vehicle lessor, Federal Law requires that any vehicle lessor receiving this recall notice must forward a copy of this notice to the lessee within ten days.

If you know the current owner or operator, please forward this letter to them.

If you would like to update your vehicle ownership or contact information, please visit https://www.toyota.com/recall/update-info-toyota. You will need your full 17-digit Vehicle Identification Number (VIN) to input the new information.

If you believe that the dealer or Toyota has failed or is unable to remedy the defect within a reasonable time or without charge, you may submit a complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Avenue S.E., Washington, D.C. 20590, or call the toll free Vehicle Safety Hot Line at 1-888-327-4236 (TTY: 1-800-424-9153), or go to https://www.safercar.gov.

has failed or is unable to remedy the defect within a reasonable time or without charge, you may submit a complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Avenue S.E., Washington, D.C. 20590, or call the toll free Vehicle Safety Hot Line at 1-888-327-4236 (TTY: 1-800-424-9153), or go to https://www.safercar.gov.

We have sent this notice in the interest of your continued satisfaction with our products. We sincerely regret any inconvenience this condition may have caused you.

Thank you for driving a Toyota .

.

Sincerely,

Toyota Motor Sales, USA

Motor Sales, USA

20TA03

RETIRO DE SEGURIDAD URGENTE

Este es un Retiro de Seguridad importante.

El remedio se realizará SIN CARGO para usted.

Este aviso aplica a su vehículo:

VIN ABCDEFGH987654321

RETIRO DE SEGURIDAD IMPORTANTE (Aviso de Remedio)

Ciertos modelo Corolla de año 2011–2019, Ciertos modelo Matrix de año 2011–2013

Ciertos modelo Avalon de año 2012–2018, Ciertos modelo Avalon Hybrid de año 2013–2018

Puede ocurrir que las bolsas de aire y/o los pretensionadores del cinturón de seguridad no se activen o se activen de forma incompleta

Retiro de Seguridad de NHTSA No. 20V-024

Estimado (nombre/apellido del cliente):

Se le envía esta notificación de acuerdo con la Ley Nacional de la oficina de Administración Nacional de Seguridad del Tráfico en las Carreteras (National Highway Traffic Safety Administration o NHTSA por sus siglas en inglés). Toyota ha decidido que existe un defecto, que se relaciona con la seguridad de los vehículos de motor en ciertos vehículos modelo Corolla de año 2011–2019, ciertos modelo Matrix de año 2011–2013, ciertos modelo Avalon de año 2012–2018 y ciertos modelo Avalon Hybrid de año 2013–2018.

ha decidido que existe un defecto, que se relaciona con la seguridad de los vehículos de motor en ciertos vehículos modelo Corolla de año 2011–2019, ciertos modelo Matrix de año 2011–2013, ciertos modelo Avalon de año 2012–2018 y ciertos modelo Avalon Hybrid de año 2013–2018.

Usted recibió esta notificación porque nuestros registros, que se basan principalmente en los datos del estado de registro y de título, indican que usted es el propietario actual.

¿Cuál es la condición?

Los vehículos sujetos están equipados con una unidad de control electrónica (ECU) de un proveedor específico que está diseñada para recibir señales de los sensores de colisión y activar las bolsas de aire y los pretensionadores de los cinturones de seguridad. La ECU pudiera no tener la protección adecuada contra cierto ruido eléctrico que pudiera ocurrir en ciertas colisiones, tales como en colisiones severos donde los automóviles embisten por atrás o por debajo a un camión de carga o un vehículo de gran tamaño. Esto puede conllevar a que las bolsas de aire y/o los pretensionadores del cinturón de seguridad no se activen o se activen de forma incompleta. La bolsa de aire y los pretensionadores de los cinturones de seguridad que no se activen como está planeado puede aumentar el riesgo de una lesión en una colisión.

¿Qué Debe Hacer?

Comuníquese con cualquier concesionario Toyota autorizado para programar una cita para que realicen el remedio tan pronto como sea posible. El remedio requerirá que se instale un nuevo repuesto. Le recomendamos que se comunique con su concesionario para programar una cita con anticipación para confirmar la disponibilidad de las piezas y reducir al mínimo sus inconvenientes.

autorizado para programar una cita para que realicen el remedio tan pronto como sea posible. El remedio requerirá que se instale un nuevo repuesto. Le recomendamos que se comunique con su concesionario para programar una cita con anticipación para confirmar la disponibilidad de las piezas y reducir al mínimo sus inconvenientes.

Su concesionario Toyota local responderá con gusto todas sus preguntas.

local responderá con gusto todas sus preguntas.

Para encontrar un concesionario cerca de usted, visite www.toyota.com/dealers.

Si desea más información sobre este y otros Retiros de Seguridad, incluyendo las preguntas frecuentes, visite www.toyota.com/recall. Ingrese el número de identificación de su vehículo de 17 dígitos (VIN) indicado arriba para revisar la información específica de su vehículo.

Si requiere más asistencia, puede comunicarse con el Centro de Experiencias del Cliente Toyota llamando al 1-888-270-9371, de lunes a viernes, de 7:00 a.m. a 7:00 p.m. y los sábados de 7:00 a.m. a 4:30 p.m., Horario del Centro.

llamando al 1-888-270-9371, de lunes a viernes, de 7:00 a.m. a 7:00 p.m. y los sábados de 7:00 a.m. a 4:30 p.m., Horario del Centro.

English version on front side

Versión en inglés en el frente

20TA03

¿Qué hará Toyota ?

?

Cualquier concesionario Toyota instalará un filtro de ruido entre el módulo de control de la bolsa de aire y su arnés de cables SIN COSTO para usted.

instalará un filtro de ruido entre el módulo de control de la bolsa de aire y su arnés de cables SIN COSTO para usted.

Este es un Retiro de Seguridad importante.

El remedio tardará aproximadamente entre una hora y una y tres cuartos de hora. Sin embargo, dependiendo de la programación de trabajo del concesionario, tal vez sea necesario tener disponible su vehículo por un plazo más largo.

¿Qué pasa si anteriormente pagó reparaciones a su vehículo por esta condición específica?

Si anteriormente pagó reparaciones a su vehículo por esta condición específica antes de recibir esta carta, usted puede ser elegible para el reembolso. Para que se considere su reembolso, envíe una copia de los detalles de su reparación (por ejemplo, una orden de reparación), comprobante de pago e información de propiedad al portal de autoservicio en línea de Toyota . Ingrese en su cuenta de propietarios de Toyota

. Ingrese en su cuenta de propietarios de Toyota en https:/www.toyota.com/owners/, haga clic en la pestaña “Resources” (Recursos), seleccione “Safety Recalls and Service Campaigns” (Retiros de seguridad y servicio) y haga clic en “Submit Reimbursement Request” (Enviar solicitud de reembolso).

en https:/www.toyota.com/owners/, haga clic en la pestaña “Resources” (Recursos), seleccione “Safety Recalls and Service Campaigns” (Retiros de seguridad y servicio) y haga clic en “Submit Reimbursement Request” (Enviar solicitud de reembolso).

Como alternativa, si prefiere enviar esta información por correo postal o por fax para que le consideren el reembolso, utilice el domicilio o número de fax que aparece a continuación:

Toyota Customer Experience Center – TSR

Customer Experience Center – TSR

Toyota Motor Sales, USA, Inc.

Motor Sales, USA, Inc.

c/o Toyota Motor North America, Inc.

Motor North America, Inc.

P O Box 259001 – SSC/CSP Reimbursements

Plano, Texas 75025-9001

FAX: 310-381-7756

Remítase a la lista de verificación de reembolsos anexa para conocer los detalles de los documentos requeridos.

¿Qué pasa si usted no es el propietario o el operador de este vehículo?

Si usted arrienda el vehículo, la ley federal requiere que todo arrendador de vehículo que reciba esta notificación del Retiro de Seguridad debe enviar una copia del aviso al arrendatario en menos de diez días.

Si conoce al propietario u operador actual, sea tan amable de enviarle esta carta.

Si quisiera actualizar la información de propiedad o de contacto de su vehículo, por favor visite https://www.toyota.com/recall/update-info-toyota. Necesitará el número de identificación del vehículo (VIN) completo de 17 dígitos para ingresar la nueva información.

Si cree que el concesionario o Toyota no ha cumplido o no ha podido arreglar el defecto en un plazo razonable o sin cargo, puede enviar una queja al Administrador, National Highway Traffic Safety Administration, 1200 New Jersey Avenue S.E., Washington, D.C. 20590, o llamar a la línea directa sin costo de los vehículos al 1-888-327-4236 (TTY: 1-800-424-9153), o visite https://www.safercar.gov.

no ha cumplido o no ha podido arreglar el defecto en un plazo razonable o sin cargo, puede enviar una queja al Administrador, National Highway Traffic Safety Administration, 1200 New Jersey Avenue S.E., Washington, D.C. 20590, o llamar a la línea directa sin costo de los vehículos al 1-888-327-4236 (TTY: 1-800-424-9153), o visite https://www.safercar.gov.

Hemos enviado esta notificación con el interés de que usted esté continuamente satisfecho con nuestros productos.

Lamentamos sinceramente cualquier inconveniente que este problema le puede haber ocasionado.

Muchas gracias por conducir un Toyota .

.

Atentamente,

Toyota Motor Sales, USA

Motor Sales, USA

◄ IMPORTANT UPDATE ►

The attached Dealer Letter has been updated. Refer to the details below.

| DATE | TOPIC |

| 02/10/2020 | Interim rental opcodes now available.

Toyota |

The most recent update in the attached Dealer Letter will be highlighted with a red box.

Please review this notification with your staff to assure that all relevant personnel have been briefed regarding this subject.

Thank you for your cooperation.

Original Publication Date: January 21, 2020

To: All Toyota Dealer Principals, General Managers, Service Managers, and Parts Managers

Dealer Principals, General Managers, Service Managers, and Parts Managers

SAFETY RECALL 20TA03 (Interim Notice 20TB03)

Certain 2011 – 2019 Model Year Corolla

Certain 2011 – 2013 Model Year Matrix

Certain 2012 – 2018 Model Year Avalon

Certain 2013 – 2018 Model Year Avalon Hybrid

Incomplete or Nondeployment of Airbags and/or Seat Belt Pretensioners May Occur

| Model / Years | Production Period | Approximate Total Vehicles | Approximate Stop Sale Dealer Inventory |

| Corolla 2011 – 2019 | Late November 2010 – Late February 2019 | 2,577,000 | 30 |

| Matrix 2011 – 2013 | Early December 2010 – Mid-June 2013 | 10,200 | 0 |

| Avalon 2012 – 2018 | Mid-May 2012 – Mid-April 2018 | 241,900 | 0 |

| Avalon HV 2013 – 2018 | Late May 2012 – Late March 2018 | 63,800 | 3 |

|

STOP! DO NOT SELL NEW VEHICLES IN DEALER INVENTORY.Refer to Dealer Inventory Procedures section for more details. |  |

On January 17, 2020, Toyota filed a Defect Information Report (DIR) with the National Highway Traffic Safety Administration (NHTSA) informing the agency of our intent to conduct a voluntary Safety Recall on certain 2011 – 2019 model year Corolla, 2011 – 2013 model year Matrix, 2012 – 2018 model year Avalon and 2013 – 2018 Avalon Hybrid vehicles.

Condition

The subject vehicles may be equipped with an electronic control unit (ECU) from a specific supplier designed to receive signals from crash sensors and deploy the airbags and seat belt pretensioners. The ECU may not have adequate protection against certain electrical noise that can occur in certain crashes, such as severe underride crashes. This can lead to incomplete or nondeployment of the airbags and/or seat belt pretensioners. Airbag non-deployment and/or lack of seat belt pretensioner operation can increase the risk or severity of injury in a crash.

Remedy

Toyota is currently preparing the remedy. When the remedy becomes available, in most cases, Toyota

is currently preparing the remedy. When the remedy becomes available, in most cases, Toyota dealers will install a noise filter between the airbag control module and its wire harness. In some cases, Toyota

dealers will install a noise filter between the airbag control module and its wire harness. In some cases, Toyota dealers may inspect the ECU to determine if the noise filter is necessary before installing it. The remedy will be at no cost to vehicle owners.

dealers may inspect the ECU to determine if the noise filter is necessary before installing it. The remedy will be at no cost to vehicle owners.

Covered Vehicles

There are approximately 2,892,900 vehicles covered by this Safety Recall. Approximately 50,000 vehicles involved in this Safety Recall were distributed to Puerto Rico.

Owner Letter Mailing Date

Toyota will notify owners by mid-March 2020.

will notify owners by mid-March 2020.

Toyota makes significant effort to obtain current customer name and address information from each state through industry resources when mailing owner letters. In the event your dealership receives a notice for a vehicle that was sold prior to the Safety Recall announcement, it is the dealership’s responsibility to forward the owner letter to the customer who purchased the vehicle.

makes significant effort to obtain current customer name and address information from each state through industry resources when mailing owner letters. In the event your dealership receives a notice for a vehicle that was sold prior to the Safety Recall announcement, it is the dealership’s responsibility to forward the owner letter to the customer who purchased the vehicle.

Please note that only owners of the covered vehicles will be notified. If you are contacted by an owner who has not yet received a notification, please verify eligibility by confirming through TIS prior to performing repairs. Dealers should perform the repair as outlined in the Technical Instructions found on TIS.

Dealer Inventory Procedures

New Vehicles in Dealership Inventory

There are approximately 33 vehicles in new dealer inventory as of January 21, 2020.

| Under Title 49, Section 30112 of the United States Code, a dealer cannot sell, offer for sale, or introduce or deliver for introduction in interstate commerce a new motor vehicle when it is aware that the vehicle does not comply with an applicable Federal Motor Vehicle Safety Standard or contains a defect related to motor vehicle safety. Further, 49 Code of Federal Regulations §577.13 requires us to provide the following advisory: It is a violation of Federal law for a dealer to deliver a new motor vehicle or any new or used item of motor vehicle equipment (including a tire) covered by this notification under a sale or lease until the defect or noncompliance is remedied.

Toyota |

| Vehicle Safety Recall completion should always be verified through TIS. We request your assistance to ensure involved vehicles are identified and not delivered prior to performing the remedy. | |

NOTE:

- New vehicles in dealer inventory subject to a Safety Recall must be remedied before delivery into commerce under a sale or lease. Dealer-to-dealer trades as well as vehicle sales between dealers should not be made until a vehicle is remedied.

- Dealers can identify if any of their new and used inventory has any open campaigns in the Vehicle Inventory Summary available in Dealer Daily (Non SET and GST dealers: https://dealerdaily.toyota.com/). The Vehicle Inventory Summary may take up to 4 hours to populate information for newly launched campaigns.

Inspection Reminder Mirror Hang Tags for Covered Vehicles in New Dealer Stock

To easily recognize vehicles involved in this Safety Recall, each dealership should utilize Inspection Reminder Hang Tags. Inside the vehicle’s glove box are stickers containing the VIN. Apply one of these stickers to the hang tag and install the hang tag in the vehicle. A sample copy of the Inspection Reminder Hang Tag has been included for your reference.

| Part Number | Description | Quantity |

| 00411-140003 | Inspection Mirror Hang Tag | 25 Per Pack |

NOTE: Dealerships can order hang tags from the Material Distribution Center (MDC).

Pre-Owned Vehicles in Dealer Inventory

Toyota typically requests that dealers NOT deliver any pre-owned vehicles in dealer inventory that are covered by a Safety Recall unless the defect has been remedied. In this case, until remedy parts are available, delivery of a pre-owned vehicle is acceptable if disclosed to the customer that the vehicle is involved in this Safety Recall and that the remedy is currently being prepared by Toyota

typically requests that dealers NOT deliver any pre-owned vehicles in dealer inventory that are covered by a Safety Recall unless the defect has been remedied. In this case, until remedy parts are available, delivery of a pre-owned vehicle is acceptable if disclosed to the customer that the vehicle is involved in this Safety Recall and that the remedy is currently being prepared by Toyota .

.

Toyota expects dealers to use the attached Customer Contact and Vehicle Disclosure Form to obtain vehicle buyer information. Dealers are expected to provide a copy of the completed form, along with the most current FAQ, to the vehicle buyer. Toyota

expects dealers to use the attached Customer Contact and Vehicle Disclosure Form to obtain vehicle buyer information. Dealers are expected to provide a copy of the completed form, along with the most current FAQ, to the vehicle buyer. Toyota and the dealer may use this information to contact the customer when the remedy becomes available.

and the dealer may use this information to contact the customer when the remedy becomes available.

Keep the completed form on file at the dealership and send a copy to quality_compliance@toyota .com. In the subject line of the email, state “Disclosure Form 20TA03/20TB03” and include the VIN.

.com. In the subject line of the email, state “Disclosure Form 20TA03/20TB03” and include the VIN.

NOTE: Dealers can identify if any of their new and used inventory has any open campaigns in the Vehicle Inventory Summary available in Dealer Daily (Non SET and GST dealers: https://dealerdaily.toyota.com/). The Vehicle Inventory Summary may take up to 4 hours to populate information for newly launched campaigns.

Toyota Certified Used Vehicle (TCUV)

Certified Used Vehicle (TCUV)

The TCUV policy prohibits the certification of any vehicle with an outstanding Safety Recall, Special Service Campaign, or Limited Service Campaign. Thus, no affected units are to be designated, sold, or delivered as a TCUV until all applicable Safety Recalls, Special Service Campaigns, and Limited Service Campaigns have been completed on that vehicle.

–

Toyota Rent-A-Car (TRAC) & Service Loaners

Rent-A-Car (TRAC) & Service Loaners

Toyota requests that dealers remove all TRAC and Service Loaner vehicles from service that are covered by a Safety Recall unless the defect has been remedied.

requests that dealers remove all TRAC and Service Loaner vehicles from service that are covered by a Safety Recall unless the defect has been remedied.

Customer Handling, Parts Ordering, and Remedy Procedures

Customer Contacts

Customers who receive the owner letter may contact your dealership with questions regarding the letter and/or the Safety Recall. Please welcome them to your dealership and answer any questions that they may have. A Q&A is provided to assure a consistent message is communicated.

Customers with additional questions or concerns are asked to please contact the Toyota Customer Experience Center (1-888-270-9371) – Monday through Friday, 7:00 am to 7:00 pm, Saturday 7:00 am to 4:30 pm Central Time.

Customer Experience Center (1-888-270-9371) – Monday through Friday, 7:00 am to 7:00 pm, Saturday 7:00 am to 4:30 pm Central Time.

Media Contacts

It is imperative that all media contacts (local and national) receive a consistent message. In this regard, all media contacts must be directed to Tania Saldana (859) 815-9968 in Toyota Corporate Communications. Please do not provide this number to customers. Please provide this contact only to media.

Corporate Communications. Please do not provide this number to customers. Please provide this contact only to media.

Warranty Reimbursement Procedures

Loaner Vehicle or Alternative Transportation Reimbursement Procedure

Until the remedy is available, customers who are uncomfortable driving their vehicle during the interim phase may receive a loaner vehicle or alternative transportation through Toyota Rent-A-CAR (TRAC) which can be claimed for $35 per day.

Rent-A-CAR (TRAC) which can be claimed for $35 per day.

| Op Code | Description |

| TB03R1 | Vehicle Rental 1-30 Days |

| TB03R2 | Vehicle Rental 31-60 Days |

NOTE:

- Rental invoice MUST be attached to all rental claims. These claims may be subject to debit if rental invoice is not attached.

- Rentals that exceed the maximum allowable daily rate will require DSPM authorization per the Toyota Transportation Assistance Policy (TTAP).

- Dealers will be allowed to file these Op Codes up to 90 days after the final phase has launched into remedy. After that time, no claims for alternative transportation reimbursement will be accepted.

Campaign Designation / Phase Decoder

|

| Examples:

19TA01 = Launched in 2019, Toyota 20TC02 = Launched in 2020, Special Service Campaign, 2nd Special Service Campaign Launched in 2020 21TE05 = Launched in 2021, Customer Support Program, 5th Customer Support Program Launched in 2021 |

Please review this entire package with your Service and Parts staff to familiarize them with the proper step-by-step procedures required to implement this Safety Recall.

Thank you for your cooperation.

TOYOTA MOTOR SALES, U.S.A., INC.

MOTOR SALES, U.S.A., INC.

SAFETY RECALL 20TA03 (Interim Notice 20TB03)

Certain 2011 – 2019 Model Year Corolla

Certain 2011 – 2013 Model Year Matrix

Certain 2012 – 2018 Model Year Avalon

Certain 2013 – 2018 Model Year Avalon Hybrid

Incomplete or Nondeployment of Airbags and/or Seat Belt Pretensioners May Occur

Frequently Asked Questions

Original Publication Date: January 21, 2020

| Q1: | What is the condition? | ||||||||||||||||||||||||

| A1: | The subject vehicles may be equipped with an electronic control unit (ECU) from a specific supplier designed to receive signals from crash sensors and deploy the airbags and seat belt pretensioners. The ECU may not have adequate protection against certain electrical noise that can occur in certain crashes, such as severe underride crashes. This can lead to incomplete or nondeployment of the airbags and/or seat belt pretensioners. Airbag non-deployment and/or lack of seat belt pretensioner operation can increase the risk or severity of injury in a crash.

| ||||||||||||||||||||||||

| Q2: | What is Toyota going to do? | ||||||||||||||||||||||||

| A2: | Toyota is currently preparing the remedy. When the remedy becomes available, in most cases, Toyota dealers will install a noise filter between the airbag control module and its wire harness. In some cases, Toyota dealers may inspect the ECU to determine if the noise filter is necessary before installing it. The remedy will be at no cost to vehicle owners.

| ||||||||||||||||||||||||

| Q3: | Which and how many vehicles are covered by this Safety Recall? | ||||||||||||||||||||||||

| A3: | There are approximately 2,892,900 vehicles covered by this Safety Recall.

| ||||||||||||||||||||||||

| Q4: | What if I previously paid for repairs related to this Safety Recall? | ||||||||||||||||||||||||

| A4: | Reimbursement consideration instructions will be provided in the owner letter.

| ||||||||||||||||||||||||

| Q5: | How does Toyota obtain my mailing information? | ||||||||||||||||||||||||

| A5: | Toyota uses an industry provider who works with each state’s Department of Motor Vehicles (DMV) to receive registration or title information, based upon the DMV records. Please make sure your registration or title information is correct.

| ||||||||||||||||||||||||

| Q6: | What if I have additional questions or concerns? | ||||||||||||||||||||||||

| A6: | If you have additional questions or concerns, please contact the Toyota Customer Experience Center at 1-888-270-9371 Monday through Friday, 7:00 am to 7:00 pm, Saturday 7:00 am to 4:30 pm Central Time.

|

INTERIM NOTICE

We are currently preparing the remedy. We will notify you again when the remedy is available.

This notice applies to your vehicle:

VIN ABCDEFGH987654321

IMPORTANT SAFETY RECALL (Interim Notice)

Certain 2011-2019 Model Year Corolla

Certain 2011–2013 Model Year Matrix

Certain 2012–2018 Model Year Avalon

Certain 2013–2018 Model Year Avalon Hybrid

Incomplete or Nondeployment of Airbags and/or Seat Belt Pretensioners May Occur NHTSA Recall No. 20V-024

Dear <FirstName/LastName>:

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act. Toyota has decided that a defect, which relates to motor vehicle safety, exists in certain 2011–2019 model year Corolla, certain 2011–2013 model year Matrix, certain 2012–2018 model year Avalon and certain 2013–2018 Avalon Hybrid vehicles.

You received this notice because our records, which are based primarily on state registration and title data, indicate that you are the current owner.

What is the condition?

The subject vehicles may be equipped with an electronic control unit (ECU) from a specific supplier that is designed to receive signals from crash sensors and deploy the airbags and seat belt pretensioners. The ECU may not have adequate protection against certain electrical noise that can occur in certain crashes, such as severe underride crashes. This can lead to incomplete or nondeployment of the airbags and/or seat belt pretensioners. Airbags and seat belt pretensioners that do not deploy as intended can increase the risk of injury in a crash.

What Should You Do?

We appreciate your patience while we prepare the remedy.

We will notify you again when the remedy is available. At this time, we expect that the remedy will be available in a few months.

Your local Toyota dealer will be more than happy to answer any of your questions.

To find a dealer near you, visit www.toyota.com/dealers

For more information on this and other Safety Recalls, including Frequently Asked Questions, visit www.toyota.com/recall. Input your full 17-digit Vehicle Identification Number (VIN) noted above to review information specific to your vehicle.

If you require further assistance, you may contact the Toyota Customer Experience Center at 1-888-270-9371 Monday through Friday, 7:00 a.m. to 7:00 p.m., Saturday 7:00 a.m. to 4:30 p.m., Central Time.

Spanish translation on back side

Traducción en español en el lado inverso

What will Toyota do?

Toyota is currently preparing the remedy. When the remedy becomes available, in most cases, Toyota dealers will install a noise filter between the airbag control module and its wire harness. In some cases, Toyota dealers may inspect the ECU to determine if the noise filter is necessary before installing it. The remedy will be FREE OF CHARGE to you.

This is an important Safety Recall.

We appreciate your patience while we prepare the remedy.

You will receive a second notification when the remedy is available.

If you have any questions or concerns while the remedy is being prepared, please contact your local authorized Toyota dealer or the Toyota Customer Experience Center at 1-888-270-9371 Monday through Friday, 7:00 a.m. to 7:00 p.m., Saturday 7:00 a.m. to 4:30 p.m., Central Time.

What if you have previously paid for repairs to your vehicle for this specific condition?

If you have previously paid for repair(s) to your vehicle for this specific condition prior to receiving this letter, you may be eligible for reimbursement. For reimbursement consideration, please submit a copy of your repair details (for example: a repair order), proof-of-payment, and ownership information to Toyota’s online, self-service portal. Log-in to your Toyota Owners account at https:/www.toyota.com/owners/, click on the “Resources” tab, select “Safety Recalls and Service Campaigns,” and click on “Submit Reimbursement Request.”

Alternatively, if you prefer to mail or fax this information for reimbursement consideration, please use the address or fax number shown below:

Toyota Customer Experience Center – TSR

Toyota Motor Sales, USA, Inc.

c/o Toyota Motor North America, Inc.

P O Box 259001 – SSC/CSP Reimbursements Plano, Texas 75025-9001

FAX: 310-381-7756

Please refer to the attached Reimbursement Checklist for required documentation details.

What if you are not the owner or operator of this vehicle?

If you are a vehicle lessor, Federal Law requires that any vehicle lessor receiving this recall notice must forward a copy of this notice to the lessee within ten days.

If you know the current owner or operator, please forward this letter to them.

If you would like to update your vehicle ownership or contact information, please visit https://www.toyota.com/recall/update-info-toyota. You will need your full 17-digit Vehicle Identification Number (VIN) to input the new information.

If you believe that the dealer or Toyota has failed or is unable to remedy the defect within a reasonable time or without charge, you may submit a complaint to the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Avenue S.E., Washington, D.C. 20590, or call the toll free Vehicle Safety Hot Line at 1-888-327-4236 (TTY: 1-800-424-9153), or go to https://www.safercar.gov.

We have sent this notice in the interest of your continued satisfaction with our products. We sincerely regret any inconvenience this condition may have caused you.

Thank you for driving a Toyota.

Sincerely,

Toyota Motor Sales, USA

20TB03 Interim

NOTIFICACIÓN TEMPORAL

Actualmente estamos preparando el remedio. Nosotros le notificaremos de nuevo cuando el remedio esté disponible.

Este aviso aplica a su vehículo:

VIN ABCDEFGH987654321

RETIRO DE SEGURIDAD IMPORTANTE (Notificación temporal)

Ciertos modelo Corolla de año 201-2019, Ciertos modelo Matrix de año 2011–2013,

Ciertos modelo Avalon de año 2012–2018, Ciertos modelo Avalon Hybrid de año 2013–2018

Puede ocurrir que las bolsas de aire y/o los pretensionadores del cinturón de seguridad no se activen o se activen de forma incompleta

Retiro de Seguridad de NHTSA No. 20V-024

Estimado (nombre/apellido del cliente):

Se le envía esta notificación de acuerdo con la Ley Nacional de la oficina de Administración Nacional de Seguridad del Tráfico en las Carreteras (National Highway Traffic Safety Administration o NHTSA por sus siglas en inglés) Toyota ha decidido que existe un defecto, que se relaciona con la seguridad de los vehículos de motor en ciertos vehículos modelo Corolla de año 2011–2019, ciertos modelo Matrix de año 2011–2013, ciertos modelo Avalon de año 2012–2018 y ciertos modelo Avalon Hybrid de año 2013–2018.

Usted recibió esta notificación porque nuestros registros, que se basan principalmente en los datos del estado de registro y de título, indican que usted es el propietario actual.

¿Cuál es la condición?

Los vehículos cuestionables pueden estar están equipados con una unidad de control electrónica (ECU) de un proveedor específico diseñada para recibir señales de los sensores de colisión y activar las bolsas de aire y los pretensionadores de los cinturones de seguridad. La ECU pudiera no tener la protección adecuada contra cierto ruido eléctrico que pudiera ocurrir en ciertas colisiones, tales como en colisiones severos donde los automóviles embisten por atrás o por debajo a un camión de carga o un vehículo de gran tamaño. Esto puede conllevar a que las bolsas de aire y/o los pretensionadores del cinturón de seguridad no se activen o se activen de forma incompleta. Bolsas de aire y pretensores del cinturón de seguridad que no se despliegan según lo previsto pueden aumentar el riesgo de lesiones en una colisión.

¿Qué Debe Hacer?

Nosotros apreciamos su paciencia mientras preparamos el remedio.

Nosotros le notificaremos de nuevo cuando el remedio esté disponible. En este momento, nosotros esperamos que el remedio esté disponible en unos pocos meses.

Su concesionario Toyota local responderá con gusto todas sus preguntas.

Para encontrar un concesionario cerca de usted, visite www.toyota.com/dealers.

Si desea más información sobre este y otros Retiros de seguridad, incluyendo las preguntas frecuentes, visite www.toyota.com/recall. Ingrese el número de identificación de su vehículo de 17 dígitos (VIN) indicado arriba para revisar la información específica de su vehículo.

Si requiere más asistencia, puede comunicarse con el Centro de Experiencias del Cliente Toyota llamando al 1-888-270-9371, de lunes a viernes, de 7:00 a.m. a 7:00 p.m., y los sábados de 7:00 a.m. a 4:30 p.m., Horario del Centro.

English version on front side

Versión en inglés en el frente

20TB03 Interim

¿Qué hará Toyota?

Toyota actualmente está preparando el remedio. Cuando el remedio esté disponible, en la mayoría de los casos, los concesionarios Toyota instalarán un filtro de ruido entre el módulo de control de la bolsa de aire y su arnés de cables. En algunos casos, los concesionarios Toyota pueden inspeccionar la ECU para determinar si el filtro de ruido es necesario antes de instalarlo. El remedio será SIN CARGO para usted.

Este es un Retiro de Seguridad importante.

Nosotros apreciamos su paciencia mientras preparamos el remedio.

Usted recibirá una segunda notificación cuando el remedio esté disponible.

Si usted tiene preguntas o inquietudes mientras se prepara el remedio, por favor comuníquese con el Centro de Experiencias del Cliente Toyota llamando al 1-888-270-9371, de lunes a viernes, de 7:00 a.m. a 7:00 p.m. y los sábados de 7:00 a.m. a 4:30 p.m., Horario del Centro.

¿Qué pasa si anteriormente pagó reparaciones a su vehículo por esta condición específica?

Si anteriormente pagó reparaciones a su vehículo por esta condición específica antes de recibir esta carta, usted puede ser elegible para el reembolso. Para que se considere su reembolso, envíe una copia de los detalles de su reparación (por ejemplo, una orden de reparación), comprobante de pago e información de propiedad al portal de autoservicio en línea de Toyota. Ingrese en su cuenta de propietarios de Toyota en https:/www.toyota.com/owners/, haga clic en la pestaña “Resources” (Recursos), seleccione “Safety Recalls and Service Campaigns” (Retiros de seguridad y servicio) y haga clic en “Submit Reimbursement Request” (Enviar solicitud de reembolso).

Como alternativa, si prefiere enviar esta información por correo postal o por fax para que le consideren el reembolso, utilice el domicilio o número de fax que aparece a continuación:

Toyota Customer Experience Center – TSR

Toyota Motor Sales, USA, Inc., c/o Toyota Motor North America, Inc.

P O Box 259001 – SSC/CSP Reimbursements, Plano, Texas 75025-9001

FAX: 310-381-7756

Remítase a la lista de verificación de reembolsos anexa para conocer los detalles de los documentos requeridos.

¿Qué pasa si usted no es el propietario o el operador de este vehículo?

Si usted arrienda el vehículo, la ley federal requiere que todo arrendador de vehículo que reciba esta notificación del Retiro de Seguridad debe enviar una copia del aviso al arrendatario en menos de diez días.

Si conoce al propietario u operador actual, sea tan amable de enviarle esta carta.

Si quisiera actualizar la información de propiedad o de contacto de su vehículo, por favor visite https://www.toyota.com/recall/update-info-toyota. Necesitará el número de identificación del vehículo (VIN) completo de 17 dígitos para ingresar la nueva información.

Si cree que el concesionario o Toyota no ha cumplido o no ha podido remediar el defecto en un plazo razonable o sin cargo, puede enviar una queja al Administrador, National Highway Traffic Safety Administration, 1200 New Jersey Avenue S.E., Washington, D.C. 20590, o llamar a la línea directa sin costo de los vehículos al 1-888-327-4236 (TTY: 1-800-424-9153), o visite https://www.safercar.gov.

Hemos enviado esta notificación con el interés de que usted esté continuamente satisfecho con nuestros productos.

Lamentamos sinceramente cualquier inconveniente que este problema le puede haber ocasionado.

Muchas gracias por conducir un Toyota.

Atentamente,

Toyota Motor Sales, USA

March 19, 2020

AMENDED DEFECT INFORMATION REPORT

(20V-024)

This supplements Toyota’s Part 573 Report of January 17, 2020 (20V-024) concerning the ZF-TRW supplemental restraint system (SRS ECU) issue on certain Toyota vehicles.

As described in Toyota’s description of corrective repair action, in some cases, Toyota may inspect the ECU to determine if the noise filter is necessary before installing it.

Toyota has determined that certain 2011-2012MY Toyota Corolla vehicles will require an inspection before installing the noise filter to determine if the ECU was manufactured by ZF-TRW and requires the noise filter remedy. As a result, those vehicles will be assigned a separate manufacturer campaign number. The other vehicles involved in the recall will remain under the original manufacturer campaign number.

The manufacturer’s campaign number are revised as noted below:

Manufacturer’s Campaign Number:

2011 – 2012MY Toyota Corolla: 20TA05

All other vehicles involved in 20V-024: [Interim / Remedy] 20TB03 / 20TA03

March 11, 2020

AMENDED DEFECT INFORMATION REPORT

(20V-024)

This supplements Toyota’s Part 573 Report of January 17, 2020 (20V-024) concerning the ZF-TRW supplemental restraint system (SRS ECU) issue on certain Toyota vehicles.

As described in Toyota’s description of corrective repair action, in some cases, Toyota may inspect the ECU to determine if the noise filter is necessary before installing it.

Toyota has determined that certain 2011-2013MY Toyota Corolla vehicles will require an inspection before installing the noise filter to determine if the ECU was manufactured by ZF-TRW and requires the noise filter remedy. As a result, those vehicles will be assigned a separate manufacturer campaign number. The other vehicles involved in the recall will remain under the original manufacturer campaign number.

The manufacturer’s campaign number are revised as noted below:

Manufacturer’s Campaign Number:

2011 – 2013MY Toyota Corolla: 20TA05

All other vehicles involved in 20V-024: [Interim / Remedy] 20TB03 / 20TA03

January 17, 2020

DEFECT INFORMATION REPORT

- Vehicle Manufacturer Name:

Toyota Motor Corporation [“TMC”]

1, Toyota-cho, Toyota-city, Aichi-pref., 471-8571, Japan

Toyota Motor Manufacturing Canada Inc. [“TMMC”]

1055 Fountain Street North, Cambridge, Ontario, Canada N3H 5K2

Toyota Motor Manufacturing, Kentucky, Inc. [“TMMK”]

1001 Cherry Blossom Way Georgetown, KY 40324

Toyota Motor Manufacturing, Mississippi, Inc. [“TMMMS”]

1200 Magnolia Way, Blue Springs, MS 38828

Affiliated U.S. Sales Company:

Toyota Motor North America, Inc. [“TMNA”]

6565 Headquarters Drive, Plano, TX 75024

Manufacturer of Airbag Control Module:

ZF Friedrichshafen AG

Löwentaler Straße 20

ZF Forum 88046 Friedrichshafen, Germany

Phone: +49 7541 77 0

Country of origin: U.S.A., UK

- Identification of Involved Vehicles and Affected Components:

Based on production records, we have determined the involved vehicle population as in the table below.

| Make/Car Line | Model Year | Manufacturer | Production Period |

| Toyota / Corolla | 2011-2019 | TMC, TMMC, TMMMS | November 23, 2010 through February 25, 2019 |

| Toyota / Corolla Matrix | 2011-2013 | TMMC | December 6, 2010 through June 18, 2013 |

| Toyota / Avalon | 2012-2018 | TMMK | May 10, 2012 through April 13, 2018 |

| Toyota / Avalon HV | 2013-2018 | TMMK | May 22, 2012 through March 29, 2018 |

| Applicability | Part Number | Part Name | Component Description |

| MY2011-2019 Toyota Corolla | 89170-02D51

89170-02D52 89170-02D53 89170-02A60 89170-02C60 89170-02G60 89170-02K90 89170-02F10 | Sensor Assy, Air Bag | Airbag Control Module |

| MY2011-2013 Toyota Corolla Matrix | 89170-02C50

89170-02C51 89170-02C52 89170-02C53 89170-02A70 | ||

| MY2012-2018 Toyota Avalon | 89170-07250

89170-07280 89170-07290 89170-07350 89170-07310 | ||

| MY2013-2018 Toyota Avalon HV | 89170-07260

89170-07300 89170-07360 89170-07320 |

Note:

(1) Although the involved vehicles are within the above production period range, not all vehicles in this range were sold in the U.S.

(2) Other Toyota or Lexus vehicles sold in the U.S. are equipped with an SRS ECU of a different design, not containing the DS84 ASIC, or are equipped with an SRS ECU containing the DS84 ASIC, but, due to different body construction and other factors, Toyota believes at this time that an occurrence of a sufficient negative transient at a timing that can affect airbag deployment in a crash is unlikely.

- Total Number of Vehicles Potentially Involved:

| Toyota Avalon: | 241,845 |

| Toyota Avalon HV: | 63,785 |

| Toyota Corolla: | 2,576,108 |

| Toyota Corolla Matrix: | 10,238 |

| Total: | 2,891,976 |

- Percentage of Vehicles Estimated to Actually Contain the Defect:

Toyota is unable to provide an estimate. Although the involved vehicles potentially are equipped with the subject ECU, damage to the application-specific integrated circuit (ASIC) that will affect airbag deployment can occur only under a very narrow set of factors and circumstances in a crash that Toyota believes to be rare. However, Toyota is unable to estimate the likelihood for this to occur in the real world.

- Description of Problem:

The subject vehicles may be equipped with an airbag control module for the supplemental restraint system (SRS ECU) manufactured by ZF-TRW. The ECU receives signals from crash sensors and deploys the airbags and seat belt pretensioners in accordance with design specifications. This ECU contains a model DS84 application-specific integrated circuit (ASIC) which controls the communication of the crash sensor signals, firing commands (i.e., when to deploy the airbag(s) and/or pretensioners), and fault information (e.g., diagnostic trouble codes).

This ASIC does not have sufficient protection against negative electrical transients that can be generated in certain severe crashes, such as an underride frontal crash where there is a large engine compartment intrusion before a significant deceleration. In these cases, the crash sensor and other powered wiring can be damaged and shorted so as to create a negative electrical transient of sufficient strength and duration to damage the ASIC before the deployment signal is received in the SRS ECU. This can lead to incomplete or nondeployment of the airbags and/or pretensioners. In model year 2014-2019 Corollas, one potential mechanism contributing to the short circuit appears to be the headlight mounting bracket engagement with the crash sensor wiring along with damage to powered wiring. In the other involved vehicles, the mechanism which could create a sufficient negative electrical transient in a crash is not fully understood and is under investigation. Airbag non-deployment and/or lack of pretensioner operation can increase the risk or severity of injury in a crash.

- Chronology of Principal Events:

2016 – Early May 2018

In early 2016, ZF-TRW met with Toyota to review a presentation it had made to NHTSA about SRS ECUs supplied to other manufacturers containing the DS84 ASIC where the ASIC sustained Electrical Overstress (EOS) damage. ZF-TRW indicated that it was not aware of such an issue with ECUs supplied to Toyota.

In September 2016, FCA filed a Part 573 report with the National Highway Traffic Safety Administration (NHTSA) describing that certain vehicles may experience a loss of airbag and seat belt pretensioner deployment capability in certain crash events due to a shorting condition resulting in a negative voltage transient that travels to the Occupant Restraint Controller (ORC) produced by ZF-TRW.

Thereafter, ZF-TRW contacted Toyota and shared information regarding FCA’s recall filing, explaining that it was related to the wire harness routing in certain FCA vehicle models and that Toyota vehicles were not affected.