| “This site contains affiliate links for which OEMDTC may be compensated” |

September 20, 2019 NHTSA CAMPAIGN NUMBER: 19V670000

Improperly Tightened Steering/Suspension Fasteners

Loose fasteners may cause a loss of vehicle control, or cause an accessory to detach from the vehicle and become a road hazard. Either of these scenarios can increase the risk of a crash or injury.

NHTSA Campaign Number: 19V670

Manufacturer Southeast Toyota Distributors, LLC

Distributors, LLC

Components STEERING, SUSPENSION

Potential Number of Units Affected 34

Summary

Southeast Toyota Distributors, LLC (SET) is recalling certain 2018-2019 Toyota

Distributors, LLC (SET) is recalling certain 2018-2019 Toyota 4Runner vehicles. During installation, certain steering and suspension components may not have been properly tightened.

4Runner vehicles. During installation, certain steering and suspension components may not have been properly tightened.

Remedy

SET will notify owners, and dealers will inspect and re-tighten the steering and suspension fasteners as necessary, free of charge. The recall is expected to begin November 19, 2019. Owners may contact SET customer service at 1-866-405-4226. SET’s number for this recall is SET19B.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Vehicle has a Recall

Attention

This is an important Safety Recall which was initiated by Southeast Toyota Distributors, LLC.

Distributors, LLC.

If you are in Florida, Georgia, Alabama, South

Carolina, or North Carolina, please refer to SET Dealer Daily to obtain instructions on how to complete this repair and submit a warranty claim.

Toyota Dealerships outside of Florida, Georgia, Alabama, South Carolina or North Carolina

SET will reimburse you for the repairs outlined in the following procedure. For repair authorization and parts ordering, please contact Southeast Toyota Distributors, LLC toll free at 1-888-851-2722, or email oordealersupport@setoyota.com.

Distributors, LLC toll free at 1-888-851-2722, or email oordealersupport@setoyota.com.

Thank you for your continued support.

Southeast Toyota Distributors, LLC

Distributors, LLC

To: All Toyota Dealer Principals, General Managers, Service Managers, and Parts Managers

Dealer Principals, General Managers, Service Managers, and Parts Managers

Subject: Safety Recall SET19B – Remedy Available

On September 20, 2019 Southeast Toyota Distributors, LLC (SET) filed a Defect Information Report (DIR) with the National Highway Traffic Safety Administration (NHTSA) initiating a Safety Recall on certain 2018 -2019 Toyota

Distributors, LLC (SET) filed a Defect Information Report (DIR) with the National Highway Traffic Safety Administration (NHTSA) initiating a Safety Recall on certain 2018 -2019 Toyota 4Runner vehicles equipped with TRD accessories installed by SET.

4Runner vehicles equipped with TRD accessories installed by SET.

Affected Vehicles:

2018 – 2019 Toyota 4Runner vehicles equipped with TRD accessories installed by SET.

4Runner vehicles equipped with TRD accessories installed by SET.

Condition:

During an audit SET found that some accessory fasteners may not have been tightened to a specified torque. If the fasteners are not properly tightened to the specified torque, the fastener could become loose, possibly causing loss of control of the vehicle or the accessory could detach from the vehicle, which could cause a crash or injury.

Remedy:

All known owners of the affected vehicles will be notified by US mail to return their vehicles to a Toyota dealer. The Toyota

dealer. The Toyota dealer will, inspect and tighten the affected fasteners with a torque wrench pursuant to instructions specified by SET, at no cost to the owner.

dealer will, inspect and tighten the affected fasteners with a torque wrench pursuant to instructions specified by SET, at no cost to the owner.

This following information is being provided to keep you informed of the filing and your degree of involvement.

1. Owner Letter Mailing Date

SET has completed remedy preparations and will begin to notify owners on or before November 19, 2019.

SET makes significant effort to obtain current customer name and address information when mailing owner letters. In the event your dealership receives a notice for a vehicle that was sold prior to the Safety Recall announcement, it is the dealership’s responsibility to forward the owner letter to the customer who purchased the vehicle.

2. New Vehicles in Dealership Inventory

Under Title 49, Section 30112(a) of the United States Code, a dealer cannot sell, offer for sale, or introduce or deliver for introduction in interstate commerce a new motor vehicle when it is aware that the vehicle does not comply with an applicable Federal Motor Vehicle Safety Standard. In addition, 49 Code of Federal Regulations §577.13 requires us to provide the following advisory: it is a violation of Federal law for a dealer to deliver a new motor vehicle or any new or used item of motor vehicle equipment (including a tire) covered by this notification under a sale or lease until the defect or noncompliance is remedied. Vehicle Safety Recall completion can be verified through TIS. Additional information will be provided as it becomes available. |

3. Inspection Reminder Mirror Hang Tags for Covered Vehicles

To easily recognize vehicles involved in this Safety Recall, each dealership should utilize Inspection Reminder Hang Tags. Please reference the VIN list provided to identify new vehicles in dealer inventory involved in this Safety Recall. Inside the vehicle’s glove box are stickers containing the VIN. Apply one of these stickers to the hang tag and install the hang tag in the vehicle. A sample copy of the Inspection Reminder Hang Tag has been included for your reference.

Note: Dealerships can order Hang Tags from the Material Distribution Center (MDC).

| Part Number | Description | Qty. |

|---|---|---|

| 00411-140003 | Inspection Mirror Hang Tag | (25 Per Pack) |

4. Pre-Owned Vehicles in Dealer Inventory

SET requests that dealers do not deliver any pre-owned vehicles in dealer inventory that is covered by a Safety Recall unless the defect has been remedied.

5. Dealer Summary Reports

Please verify eligibility by confirming through TIS and inspecting the vehicle prior to performing repairs.

6. Number and Identification of Covered Vehicles

There are approximately 34 vehicles covered by this Noncompliance Recall in the U.S. and Puerto Rico.

Please note that only owners of the covered vehicles will be notified. If a dealer is contacted by an owner who has not yet received the notification, please instruct the dealer personnel to verify coverage by confirming through TIS and inspecting the vehicle. Dealers should perform the procedure as outlined in the Technical Instructions located on TIS.

7. Parts Ordering

| Part Number | Part Name | Qty |

|---|---|---|

| N/A | N/A | N/A |

8. Technician Training Requirements

All dealership technicians performing this recall are required to successfully complete the most current version of E-Learning course “Safety Recall and Service Campaign Essentials”. To ensure that all vehicles have the repair performed correctly; technicians performing this recall are required to have successfully completed E-learning course SC18A (if you had previously completed E-learning Course SC13B, you do not have to take SC18A), in addition to “Safety Recall and Service Campaign Essentials”, and currently hold at least one of the following certification levels:

- Toyota

Expert

Expert - Master

- Master Diagnostic Technicians

9. Remedy Procedures

Please refer to TIS for Technical Instructions on repair. Conduct all applicable, non-completed Safety Recall and Service Campaigns on the vehicle during the time of appointment.

10 Warranty Reimbursement Procedure

Certain 2018 – 2019 Toyota 4Runner vehicles equipped with TRD accessories installed by SET 4Runner vehicles equipped with TRD accessories installed by SET |

|

SET vendor warranty claim should be submitted as follows:

| OP CODE | DESCRIPTION | TIME | OFP | T1 | T2 |

| AR19B1 | Accessory Torque Validation | 2.0 | 00016-SPECL | 99 | 99 |

| Additional Claim information: | |||||

| Replacement Parts: | N/A, leave blank | ||||

| Sublet: | N/A, leave blank | ||||

| Condition: | SET19B | ||||

| Cause: | SET19B | ||||

| Remedy: | Perform Torque Validation | ||||

| Claim Attachment: | SET19B Torque Validation Form must be attached to AW CPS claim. | ||||

The flat rate times include 0.1 hours for administrative cost per unit for the dealership.

If you are a dealer located outside of the Southeast Region, email oordealersupport@setoyota.com attach copy of RO invoice for payment processing.

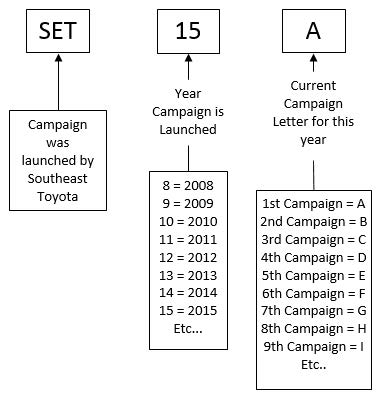

Campaign Designation Decoder

11. Repair Quality Confirmation

Not required for this Recall.

12. Technical Questions

If you are a SET dealership associate and have any questions, please contact your Field Technical Specialist. If your dealer is outside the Southeast Toyota Region and have technical questions please contact SET at 1-888-851-2722, press 6 for recall support.

Region and have technical questions please contact SET at 1-888-851-2722, press 6 for recall support.

13. Media Contacts

In the event you are contacted by the News media, it is imperative that all media contacts (local and national) receive a consistent message. In this regard, all media contacts must be directed to SET Corporate Communications 954-363-6285. (Please do not provide this number to customers.)

14. Customer Contacts

A FAQ is attached to help respond to any customer concerns. If the customer has any further questions, they are requested to contact the Southeast Toyota (SET) Customer Relations Center at 1-866-301-6859, press 1 for Southeast Toyota

(SET) Customer Relations Center at 1-866-301-6859, press 1 for Southeast Toyota and SET will return the call within 24 hours between 8:30 am and 5 pm eastern standard time.

and SET will return the call within 24 hours between 8:30 am and 5 pm eastern standard time.

Please review this entire package with your Service and Parts staff to familiarize them with the proper stepby-step procedures required to implement this Safety Recall.

Thank you for your cooperation

Southeast Toyota Distributors, LLC.

Distributors, LLC.

4RUNNER TORQUE RECALL-SET19B

QUESTIONS & ANSWERS

Certain Model Year 2018 through 2019 4Runner vehicles equipped with TRD accessories installed by SET.

Background: On September 20, 2019 Southeast Toyota Distributors, LLC. (“SET”) filed a Defect Information Report with the National Highway Traffic Safety Administration (NHTSA) informing the agency of its intent to conduct a voluntary Safety Recall on certain 2018 through 2019 4Runner vehicles equipped with TRD accessories installed by SET. There are approximately 34 vehicles covered by this recall.

Distributors, LLC. (“SET”) filed a Defect Information Report with the National Highway Traffic Safety Administration (NHTSA) informing the agency of its intent to conduct a voluntary Safety Recall on certain 2018 through 2019 4Runner vehicles equipped with TRD accessories installed by SET. There are approximately 34 vehicles covered by this recall.

Affected Vehicles: Certain 2018 through 2019 4Runner vehicles equipped with TRD accessories installed by SET.

1. What is the condition?

During an audit SET found that some accessory fasteners may not have been tightened to a specified torque. If the fasteners are not properly tightened to the specified torque, the fastener could come loose, possibly causing loss of control of the vehicle or the accessory could detach from the vehicle, which could cause a crash or injury.

2. Why are only certain vehicles covered by this Safety Recall?

SET undertook an investigation to determine the scope of the issue and the potential consequence. The investigation found that the issue was limited to the use of a specific model of torque wrench at a specific location.

The audit indicated that 34 vehicles were missing torque validation data.

3. How many vehicles are involved?

SET estimates that approximately 34 vehicles are affected by this recall.

4. Are there any other Toyota vehicles affected?

vehicles affected?

No, there are no other Toyota vehicles affected.

vehicles affected.

6. What is SET going to do?

All known owners of the affected vehicles will be notified by US mail to return their vehicles to a Toyota dealer. The Toyota

dealer. The Toyota dealer will, inspect and tighten the affected fasteners with a torque wrench pursuant to instructions specified by SET, at no cost to you.

dealer will, inspect and tighten the affected fasteners with a torque wrench pursuant to instructions specified by SET, at no cost to you.

7. Is there any cost?

These actions will be performed at no charge.

8. How long will the process take?

The corrective action will take approximately one hour or less. However, depending upon the dealer’s work schedule, it may be necessary for the owner to make the vehicle available for a longer period of time.

9. Is my vehicle covered by this Safety Recall?

Owners of the affected vehicles will receive a Safety Recall letter from Southeast Toyota Distributors, LLC informing them of this safety recall campaign. In the meantime, owners may contact any Toyota

Distributors, LLC informing them of this safety recall campaign. In the meantime, owners may contact any Toyota dealer to verify if their vehicle is covered by this campaign.

dealer to verify if their vehicle is covered by this campaign.

10. What if an owner has additional questions or concerns?

Owners with questions or additional concerns are asked to contact the Southeast Toyota Distributors, LLC. SET Customer Assistance Center toll free at 1-800-301-6859 Monday through Friday, 8:30 am to 5:00 pm Eastern Standard Time.

Distributors, LLC. SET Customer Assistance Center toll free at 1-800-301-6859 Monday through Friday, 8:30 am to 5:00 pm Eastern Standard Time.

Attention

This is an important Safety Recall which was initiated by Southeast Toyota Distributors, LLC.

Distributors, LLC.

If you are in Florida, Georgia, Alabama, South

Carolina, or North Carolina, please refer to SET Dealer Daily to obtain instructions on how to complete this repair and submit a warranty claim.

Toyota Dealerships outside of Florida, Georgia, Alabama, South Carolina or North Carolina

SET will reimburse you for the repairs outlined in the following procedure. For repair authorization and parts ordering, please contact Southeast Toyota Distributors, LLC toll free at 1-888-851-2722, or email oordealersupport@setoyota.com.

Distributors, LLC toll free at 1-888-851-2722, or email oordealersupport@setoyota.com.

Thank you for your continued support.

Southeast Toyota Distributors, LLC

Distributors, LLC

TECHNICAL INSTRUCTIONS

FOR

VOLUNTARY SAFETY RECALL CAMPAIGN SET19B

TORQUE VERIFICATION ON VARIOUS COMPONENTS

CERTAIN 2018-2019 MODEL YEAR 4RUNNER

All dealership technicians performing this recall are required to successfully complete the most current version of ELearning course “Safety Recall and Service Campaign Essentials”. To ensure that all vehicles have the repair performed correctly; technicians performing this recall are required to have successfully completed E-learning course SC18A (if you had previously completed E-learning Course SC13B, you do not have to take SC18A), in addition to “Safety Recall and Service Campaign Essentials”, and currently hold at least one of the following certification levels:

- Toyota

Expert

Expert - Master

- Master Diagnostic Technicians

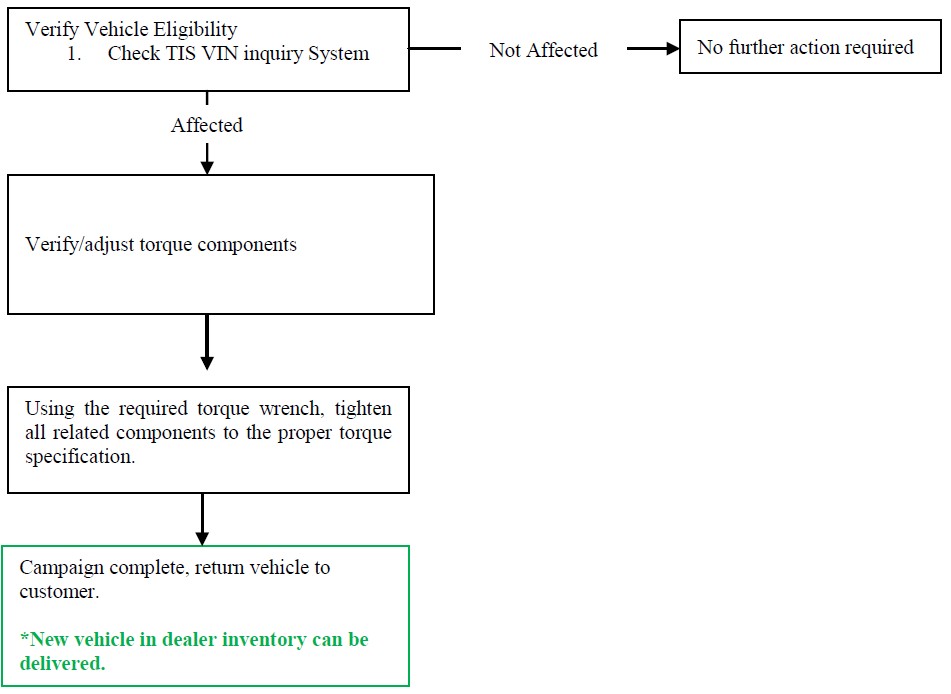

OPERATION FLOW CHART

IDENTIFICATION OF AFFECTED VEHICLES

NOTE:

- Check the TIS Vehicle Inquiry System to confirm the VIN is involved in this SSC and that the campaign has not already been completed prior to dealer shipment or by another dealer.

- Southeast Toyota

warranty will not reimburse dealers for repairs conducted on vehicles that are not affected or were completed by another dealer.

warranty will not reimburse dealers for repairs conducted on vehicles that are not affected or were completed by another dealer.

PREPARATION

A. PARTS

None required

B. TOOLS & EQUIPMENT

- Digital Torque wrench

- Standard hand tools

BACKGROUND

SET’s investigation found that a specific model of Atlas Copco Torque wrench utilized in the 4Runner accessory line was failing to consistently upload the torque data to the Atlas Copco system due to poor Wi-Fi connectivity at the Talleyrand facility. This recall is to confirm that accessories installed with this torque wrench were properly torqued to the installation specifications.

WARRANTY INFORMATION

For Dealers located in the Southeast Region, Florida, Georgia, Alabama, South Carolina, or North Carolina, Submit Warranty claim utilizing the information below.

| OP CODE | DESCRIPTION | TIME | OFP | T1 | T2 |

| AR19B1 | Accessory Torque Validation | 2.0 | 00016-SPECL | 99 | 99 |

| Additional Claim information: | |||||

| Replacement Parts: | N/A, leave blank | ||||

| Sublet: | N/A, leave blank | ||||

| Condition: | SET19B | ||||

| Cause: | SET19B | ||||

| Remedy: | Perform Torque Validation | ||||

| Claim Attachment: | SET19B Torque Validation Form must be attached to AW CPS claim. | ||||

The flat rate times include 0.1 hours for administrative cost per unit for the dealership.

If you are a dealer located outside of the Southeast Region, email oordealersupport@setoyota.com attach copy of RO invoice for payment processing.

WORK PROCEDURE

Note: SET19B Instructions outline a process which requires the SET19B Torque Validation Form located at the end of this document be completed. SET requests this form be scanned and attached to the SET warranty claim.

- Lift vehicle on suitable hoist.

- Remove Tire and Wheel assemblies from vehicle.

- Remove TRD skid plate from front of vehicle. (Fig. 1)

- Use a 14mm socket to remove the two rear bolts and loosen the two front bolts attached to the Skid Plate. Remove the Skid Plate and retain it and the bolts for reinstallation.

- Verify torque of left and right side Upper Shock Nuts, Items A1A6 on SET19B Torque form.

- Use a 14mm crowfoot to torque the nuts on the upper side of the front shock absorber with coil spring assembly (Refer to Fig. 2).

- Set torque wrench higher than upper range limit.

- Slowly apply torque until the fastener starts to rotate.

- Document reading on SET19B Torque form under initial values.

- If any measurement is out of specified range: loosen, retorque to specified value. Record values on SET19B torque form.

- Torque, with crowfoot:

- Range: 56-93 N-m (41-69 ft-lbf)

- Specified: 65 N·m (663 kgf·cm, 48 ft·lbf)

- Torque, without crowfoot:

- Range: 62-102 N-m (46-75 ft-lbf)

- Specified: 71 N·m (724 kgf·cm, 52 ft·lbf)

- Verify torque of the left and right lower ball joint attachment bolts (Fig. 3). Items B1-B4 on SET19B Torque form.

- Use a 19mm socket to torque bolts.

- Set torque wrench higher than upper range limit.

- Slowly apply torque until the fastener starts to rotate.

- Document reading on SET19B Torque form under initial values.

- If any measurement is out of specified range: loosen, retorque to specified value. Record values on SET19B torque form.

- Torque:

- Range: 139-229 N-m (103-169 ft-lbf)

- Specified: 160 N·m (1631 kgf·cm, 118 ft·lbf)

- Verify torque of left and right side front lower control arm Bolts (Fig. 4) Items C1-C4 on SET19B Torque Form.

- Use a 22mm socket to torque the front and rear lower control arm bolts (Fig. 8-2).

- Set torque wrench higher than upper range limit.

- Slowly apply torque until the fastener starts to rotate.

- Document reading on SET19B Torque form under initial values.

- If any measurement is out of specified range: loosen, retorque to specified value. Record values on SET19B torque form.

- Torque:

- Range: 152-251 N-m (112-185 ft-lbf)

- Specified: 175 N·m (1785 kgf·cm, 129 ft·lbf)

- Verify Torque of driver side and passenger side tie rod end locking nuts. (Fig. 5) Items D1 and D2 on SET19B Torque Form.

- Use a 22mm crowfoot to torque the front and rear lower control arm bolts.

- Set torque wrench higher than upper range limit.

- Slowly apply torque until the fastener starts to rotate.

- Document reading on SET19B Torque form under initial values.

- If any measurement is out of specified range: loosen, retorque to specified value. Record values on SET19B torque form.

- Torque:

- Range: 76-126 N-m (56-93 ft-lbf)

- Specified: 88 N·m (897 kgf·cm, 65 ft·lbf)

- Verify Torque of driver side and passenger side front lower shock bolts. (Fig. 6) Items E1 and E2 on torque Form.

- Use a 19mm wrench and 19mm socket to torque the front lower shock bolts.

- Set torque wrench higher than upper range limit.

- Slowly apply torque until the fastener starts to rotate.

- Document reading on SET19B Torque form under initial values.

- If any measurement is out of specified range: loosen, retorque to specified value. Record values on SET19B torque form.

- Torque:

- Range: 82-136 N-m (61-100 ft-lbf)

- Specified: 95 N·m (969 kgf·cm, 70 ft·lbf)

- Reinstall TRD skid plate and verify Torque. (Fig. 7)

- Use a 14mm wrench torque the front lower shock bolts.

- Torque: 30 N·m (306 kgf·cm, 22 ft·lbf)

- Document Torque on SET19B Torque form.

- F1-4 for skid plate

- Use a 14mm wrench torque the front lower shock bolts.

- Verify Torque of driver side and passenger Rear lower shock bolt. (Fig. 8) Items G1 and G2 on torque Form.

- Use a 19mm socket to torque the front lower shock bolts.

- Set torque wrench higher than upper range limit.

- Slowly apply torque until the fastener starts to rotate.

- Document reading on SET19B Torque form under initial values.

- If any measurement is out of specified range: loosen, retorque to specified value. Record values on SET19B torque form.

- Torque:

- Range: 82-136 N-m (61-100 ft-lbf)

- Specified: 98 N·m (1000 kgf·cm, 72 ft·lbf)

- Reinstall tire and wheel assemblies (Fig. 9)

- Review Torque form to verify completion.

- Dealer should retain a copy with the RO.

- Torque form must be attached to warranty claim submitted to SET.

APPENDIX

A. CAMPAIGN DESIGNATION DECODER

| SET19B Torque Validation Form | VIN: | ||||

| FRONT UPPER SHOCK NUTS | LEFT SIDE | RIGHT SIDE | |||

| Initial Value | Re-torque Value | Initial Value | Re-torque Value | ||

| A1: | A4: | ||||

| A2: | A5: | ||||

| A3: | A6: | ||||

Note: “Re-torque Value” is only needed if the “Initial Value” is out of the range:

| |||||

| LOWER BALL JOINT ATTACHMENT BOLTS | LEFT SIDE | RIGHT SIDE | |||

| Initial Value | Re-torque Value | Initial Value | Re-torque Value | ||

| B1: | B3: | ||||

| B2: | B4: | ||||

Note: “Re-torque Value” is only needed if the “Initial Value” is out of the range:

| |||||

| LOWER CONTROL ARM BOLTS | LEFT SIDE | RIGHT SIDE | |||

| Initial Value | Re-torque Value | Initial Value | Re-torque Value | ||

| C1: | C3: | ||||

| C2: | C4: | ||||

Note: “Re-torque Value” is only needed if the “Initial Value” is out of the range:

| |||||

| TIE ROD END LOCKING NUT | LEFT SIDE | RIGHT SIDE | |||

| Initial Value | Re-torque Value | Initial Value | Re-torque Value | ||

| D1: | D2: | ||||

Note: “Re-torque Value” is only needed if the “Initial Value” is out of the range:

| |||||

| FRONT LOWER SHOCK BOLTS | LEFT SIDE | RIGHT SIDE | |||

| Initial Value | Re-torque Value | Initial Value | Re-torque Value | ||

| E1: | E2: | ||||

Note: “Re-torque Value” is only needed if the “Initial Value” is out of the range:

| |||||

| TRD SKID PLATE | LEFT | SIDE | RIGHT SIDE | ||

| Torque | Value | Torque Value | |||

| F1: | F3: | ||||

| F2 | F4: | ||||

| REAR LOWER SHOCK BOLTS | LEFT | SIDE | RIGHT SIDE | ||

| Initial Value | Re-torque Value | Initial Value | Re-torque Value | ||

| G1: | G2: | ||||

Note: “Re-torque Value” is only needed if the “Initial Value” is out of the range:

| |||||

| WHEELS | LEFT | SIDE | RIGHT SIDE | ||

| Left Front | Left Rear | Right Front | Right Rear | ||

SEOCONTENT-START

Attention

This is an important Safety Recall which was initiated

by Southeast Toyota Distributors, LLC.

Distributors, LLC.

If you are in Florida, Georgia, Alabama, South

Carolina, or North Carolina, please refer to SET

Dealer Daily to obtain instructions on how to complete

this repair and submit a warranty claim.

Toyota Dealerships outside of Florida, Georgia,

Dealerships outside of Florida, Georgia,

Alabama, South Carolina or North Carolina

SET will reimburse you for the repairs outlined in the

following procedure. For repair authorization and

parts ordering, please contact Southeast Toyota

Distributors, LLC toll free at 1-888-851-2722, or

email oordealersupport@setoyota.com.

Thank you for your continued support.

Southeast Toyota Distributors, LLC

Distributors, LLC

To: All Toyota Dealer Principals, General Managers, Service Managers, and Parts Managers

Dealer Principals, General Managers, Service Managers, and Parts Managers

Subject: Safety Recall SET19B – Remedy Available

On September 20, 2019 Southeast Toyota Distributors, LLC (SET) filed a Defect Information Report (DIR) with the National

Distributors, LLC (SET) filed a Defect Information Report (DIR) with the National

Highway Traffic Safety Administration (NHTSA) initiating a Safety Recall on certain 2018 -2019 Toyota 4Runner vehicles

4Runner vehicles

equipped with TRD accessories installed by SET.

Affected Vehicles:

2018 – 2019 Toyota 4Runner vehicles equipped with TRD accessories installed by SET.

4Runner vehicles equipped with TRD accessories installed by SET.

Condition:

During an audit SET found that some accessory fasteners may not have been tightened to a specified torque. If the fasteners

are not properly tightened to the specified torque, the fastener could become loose, possibly causing loss of control of the

vehicle or the accessory could detach from the vehicle, which could cause a crash or injury.

Remedy:

All known owners of the affected vehicles will be notified by US mail to return their vehicles to a Toyota dealer. The Toyota

dealer. The Toyota

dealer will, inspect and tighten the affected fasteners with a torque wrench pursuant to instructions specified by SET, at no

cost to the owner.

This following information is being provided to keep you informed of the filing and your degree of involvement.

1. Owner Letter Mailing Date

SET has completed remedy preparations and will begin to notify owners on or before November 19, 2019.

SET makes significant effort to obtain current customer name and address information when mailing owner letters. In the event

your dealership receives a notice for a vehicle that was sold prior to the Safety Recall announcement, it is the dealership’s

responsibility to forward the owner letter to the customer who purchased the vehicle.

2. New Vehicles in Dealership Inventory

Under Title 49, Section 30112(a) of the United States Code, a dealer cannot sell, offer for sale, or introduce or deliver for

introduction in interstate commerce a new motor vehicle when it is aware that the vehicle does not comply with an applicable

Federal Motor Vehicle Safety Standard. In addition, 49 Code of Federal Regulations §577.13 requires us to provide the

following advisory: it is a violation of Federal law for a dealer to deliver a new motor vehicle or any new or used item of motor

vehicle equipment (including a tire) covered by this notification under a sale or lease until the defect or noncompliance is

remedied.

Vehicle Safety Recall completion can be verified through TIS. Additional information will be provided as it becomes available.

TOYOTA

Southeast Toyota Distributors, LLC

Distributors, LLC

Technical Center

9983 Pritchard Rd.

Jacksonville, FL 32219

(904) 378-4839

S a f e t y R e c a l l S E T 1 9 B P a g e | 2

3. Inspection Reminder Mirror Hang Tags for Covered Vehicles

To easily recognize vehicles involved in this Safety Recall, each dealership should utilize Inspection Reminder Hang Tags. Please

reference the VIN list provided to identify new vehicles in dealer inventory involved in this Safety Recall. Inside the vehicle’s glove box

are stickers containing the VIN. Apply one of these stickers to the hang tag and install the hang tag in the vehicle. A sample copy of the

Inspection Reminder Hang Tag has been included for your reference.

Note: Dealerships can order Hang Tags from the Material Distribution Center (MDC).

Part Number Description Qty.

00411-140003 Inspection Mirror Hang Tag (25 Per Pack)

4. Pre-Owned Vehicles in Dealer Inventory

SET requests that dealers do not deliver any pre-owned vehicles in dealer inventory that is covered by a Safety Recall unless the

defect has been remedied.

5. Dealer Summary Reports

Please verify eligibility by confirming through TIS and inspecting the vehicle prior to performing repairs.

6. Number and Identification of Covered Vehicles

There are approximately 34 vehicles covered by this Noncompliance Recall in the U.S. and Puerto Rico.

Please note that only owners of the covered vehicles will be notified. If a dealer is contacted by an owner who has not yet received

the notification, please instruct the dealer personnel to verify coverage by confirming through TIS and inspecting the vehicle.

Dealers should perform the procedure as outlined in the Technical Instructions located on TIS.

7. Parts Ordering

Part Number Part Name Qty

N/A N/A N/A

8. Technician Training Requirements

All dealership technicians performing this recall are required to successfully complete the most current version of E-Learning

course “Safety Recall and Service Campaign Essentials”. To ensure that all vehicles have the repair performed correctly;

technicians performing this recall are required to have successfully completed E-learning course SC18A (if you had previously

completed E-learning Course SC13B, you do not have to take SC18A), in addition to “Safety Recall and Service Campaign

Essentials”, and currently hold at least one of the following certification levels:

• Toyota Expert

Expert

• Master

• Master Diagnostic Technicians

9. Remedy Procedures

Please refer to TIS for Technical Instructions on repair. Conduct all applicable, non-completed Safety Recall and Service

Campaigns on the vehicle during the time of appointment.

S a f e t y R e c a l l S E T 1 9 B P a g e | 3

10. Warranty Reimbursement Procedure

Certain 2018 – 2019 Toyota 4Runner vehicles equipped with TRD accessories installed by SET

4Runner vehicles equipped with TRD accessories installed by SET

SET vendor warranty claim should be submitted as follows:

OP CODE DESCRIPTION TIME OFP T1 T2

AR19B1 Accessory Torque Validation 2.0 00016-SPECL 99 99

Additional Claim information:

Replacement Parts: N/A, leave blank

Sublet: N/A, leave blank

Condition: SET19B

Cause: SET19B

Remedy: Perform Torque Validation

Claim Attachment: SET19B Torque Validation Form must be attached to AW CPS claim.

The flat rate times include 0.1 hours for administrative cost per unit for the dealership.

If you are a dealer located outside of the Southeast Region, email oordealersupport@setoyota.com attach

copy of RO invoice for payment processing.

Verify Vehicle Eligibility

1. Check TIS VIN inquiry System Not Affected No further action required

Affected

Verify/adjust torque components

Using the required torque wrench, tighten

all related components to the proper torque

specification.

Campaign complete, return vehicle to

customer.

*New vehicle in dealer inventory can be

delivered.

S a f e t y R e c a l l S E T 1 9 B P a g e | 4

Campaign Designation Decoder

Examples:

SET14A = Launched in 2014, Remedy Phase, 1st Campaign Launched in 2014

SET14B = Launched in 2014, Remedy Phase, 2nd Campaign Launched in 2014

SET15A = Launched in 2015, Remedy Phase, 1st Campaign Launched in 2015

11. Repair Quality Confirmation

Not required for this Recall.

12. Technical Questions

If you are a SET dealership associate and have any questions, please contact your Field Technical Specialist. If your dealer is

outside the Southeast Toyota Region and have technical questions please contact SET at 1-888-851-2722, press 6 for recall

Region and have technical questions please contact SET at 1-888-851-2722, press 6 for recall

support.

13. Media Contacts

In the event you are contacted by the News media, it is imperative that all media contacts (local and national) receive a

consistent message. In this regard, all media contacts must be directed to SET Corporate Communications 954-363-6285. (Please

do not provide this number to customers.)

14. Customer Contacts

A FAQ is attached to help respond to any customer concerns. If the customer has any further questions, they are requested to

contact the Southeast Toyota (SET) Customer Relations Center at 1-866-301-6859, press 1 for Southeast Toyota

(SET) Customer Relations Center at 1-866-301-6859, press 1 for Southeast Toyota and SET will

and SET will

return the call within 24 hours between 8:30 am and 5 pm eastern standard time.

Please review this entire package with your Service and Parts staff to familiarize them with the proper stepby-

step procedures required to implement this Safety Recall.

Thank you for your cooperation

Southeast Toyota Distributors, LLC.

Distributors, LLC.

4RUNNER TORQUE RECALL-SET19B

QUESTIONS & ANSWERS

Certain Model Year 2018 through 2019 4Runner vehicles equipped with TRD accessories installed by SET.

Background: On September 20, 2019 Southeast Toyota Distributors, LLC. (“SET”) filed a Defect Information Report

Distributors, LLC. (“SET”) filed a Defect Information Report

with the National Highway Traffic Safety Administration (NHTSA) informing the agency of its intent to conduct a voluntary

Safety Recall on certain 2018 through 2019 4Runner vehicles equipped with TRD accessories installed by SET.

There are approximately 34 vehicles covered by this recall.

Affected Vehicles: Certain 2018 through 2019 4Runner vehicles equipped with TRD accessories installed by SET.

1. What is the condition?

During an audit SET found that some accessory fasteners may not have been tightened to a specified torque. If

the fasteners are not properly tightened to the specified torque, the fastener could come loose, possibly causing

loss of control of the vehicle or the accessory could detach from the vehicle, which could cause a crash or injury.

2. Why are only certain vehicles covered by this Safety Recall?

SET undertook an investigation to determine the scope of the issue and the potential consequence. The

investigation found that the issue was limited to the use of a specific model of torque wrench at a specific location.

The audit indicated that 34 vehicles were missing torque validation data.

3. How many vehicles are involved?

SET estimates that approximately 34 vehicles are affected by this recall.

4. Are there any other Toyota vehicles affected?

vehicles affected?

No, there are no other Toyota vehicles affected.

vehicles affected.

6 What is SET going to do?

All known owners of the affected vehicles will be notified by US mail to return their vehicles to a Toyota dealer.

dealer.

The Toyota dealer will, inspect and tighten the affected fasteners with a torque wrench pursuant to instructions

dealer will, inspect and tighten the affected fasteners with a torque wrench pursuant to instructions

specified by SET, at no cost to you.

7. Is there any cost?

These actions will be performed at no charge.

8. How long will the process take?

The corrective action will take approximately one hour or less. However, depending upon the dealer’s work

schedule, it may be necessary for the owner to make the vehicle available for a longer period of time.

9. Is my vehicle covered by this Safety Recall?

Owners of the affected vehicles will receive a Safety Recall letter from Southeast Toyota Distributors, LLC informing

Distributors, LLC informing

them of this safety recall campaign. In the meantime, owners may contact any Toyota dealer to verify if their

dealer to verify if their

vehicle is covered by this campaign.

10. What if an owner has additional questions or concerns?

Owners with questions or additional concerns are asked to contact the Southeast Toyota Distributors, LLC. SET

Distributors, LLC. SET

Customer Assistance Center toll free at 1-800-301-6859 Monday through Friday, 8:30 am to 5:00 pm Eastern

Standard Time.

Attention

This is an important Safety Recall which was initiated

by Southeast Toyota Distributors, LLC.

Distributors, LLC.

If you are in Florida, Georgia, Alabama, South

Carolina, or North Carolina, please refer to SET

Dealer Daily to obtain instructions on how to complete

this repair and submit a warranty claim.

Toyota Dealerships outside of Florida, Georgia,

Dealerships outside of Florida, Georgia,

Alabama, South Carolina or North Carolina

SET will reimburse you for the repairs outlined in the

following procedure. For repair authorization and

parts ordering, please contact Southeast Toyota

Distributors, LLC toll free at 1-888-851-2722, or

email oordealersupport@setoyota.com.

Thank you for your continued support.

Southeast Toyota Distributors, LLC

Distributors, LLC

S a f e t y R e c a l l S E T 1 9

1 | P a g e

Southeast Toyota Distributors September 20, 2019

Distributors September 20, 2019

TECHNICAL INSTRUCTIONS

FOR

VOLUNTARY SAFETY RECALL CAMPAIGN SET19B

TORQUE VERIFICATION ON VARIOUS COMPONENTS

CERTAIN 2018-2019 MODEL YEAR 4RUNNER

All dealership technicians performing this recall are required to successfully complete the most current version of ELearning

course “Safety Recall and Service Campaign Essentials”. To ensure that all vehicles have the repair performed

correctly; technicians performing this recall are required to have successfully completed E-learning course SC18A (if

you had previously completed E-learning Course SC13B, you do not have to take SC18A), in addition to “Safety Recall

and Service Campaign Essentials”, and currently hold at least one of the following certification levels:

● Toyota Expert

Expert

● Master

● Master Diagnostic Technicians

S a f e t y R e c a l l S E T 1 9

2 | P a g e

Southeast Toyota Distributors September 20, 2019

Distributors September 20, 2019

OPERATION FLOW CHART

Affected

Verify vehicle eligibility Not Affected No further action required

1. Check the TIS vehicle inquiry system

Campaign Complete.

Return the vehicle to the customer

New Vehicle in Dealer Inventory can now

be delivered.

Verify/adjust torque of components

Using the required torque wrench,

tighten all related compenets to the

proper torque specification

IDENTIFICATION OF AFFECTED VEHICLES

NOTE:

● Check the TIS Vehicle Inquiry System to confirm the VIN is involved in this SSC and that the campaign has

not already been completed prior to dealer shipment or by another dealer.

● Southeast Toyota warranty will not reimburse dealers for repairs conducted on vehicles that are not

warranty will not reimburse dealers for repairs conducted on vehicles that are not

affected or were completed by another dealer.

PREPARATION

A. PARTS

None required

B. TOOLS & EQUIPMENT

1. Digital Torque wrench

2. Standard hand tools

BACKGROUND

SET’s investigation found that a specific model of Atlas Copco Torque wrench utilized in the 4Runner accessory

line was failing to consistently upload the torque data to the Atlas Copco system due to poor Wi-Fi connectivity

at the Talleyrand facility. This recall is to confirm that accessories installed with this torque wrench were

properly torqued to the installation specifications.

S a f e t y R e c a l l S E T 1 9 B

WARRANTY INFORMATION

For Dealers located in the Southeast Region, Florida, Georgia, Alabama, South Carolina, or North Carolina, Submit

Warranty claim utilizing the information below.

OP CODE DESCRIPTION TIME OFP T1 T2

AR19B1 Accessory Torque Validation 2.0 00016-SPECL 99 99

Additional Claim information:

Replacement Parts: N/A, leave blank

Sublet: N/A, leave blank

Condition: SET19B

Cause: SET19B

Remedy: Perform Torque Validation

Claim Attachment: SET19B Torque Validation Form must be attached to AW CPS claim.

The flat rate times include 0.1 hours for administrative cost per unit for the dealership.

If you are a dealer located outside of the Southeast Region, email oordealersupport@setoyota.com attach

copy of RO invoice for payment processing.

WORK PROCEDURE

Note: SET19B Instructions outline a process which requires the SET19B Torque Validation Form located at the end of

this document be completed. SET requests this form be scanned and attached to the SET warranty claim.

1. Lift vehicle on suitable hoist.

2. Remove Tire and Wheel assemblies from vehicle.

3. Remove TRD skid plate from front of vehicle. (Fig. 1)

a. Use a 14mm socket to remove the two rear bolts and loosen

the two front bolts attached to the Skid Plate. Remove the

Skid Plate and retain it and the bolts for reinstallation.

Fig. 1

Southeast Toyota Distributors September 20, 2019

Distributors September 20, 2019

3 | P a g e

S a f e t y R e c a l l S E T 1 9

4 | P a g e

Southeast Toyota Distributors September 20, 2019

Distributors September 20, 2019

4. Verify torque of left and right side Upper Shock Nuts, Items A1-

A6 on SET19B Torque form.

a. Use a 14mm crowfoot to torque the nuts on the upper side

of the front shock absorber with coil spring assembly (Refer

to Fig. 2).

b. Set torque wrench higher than upper range limit.

c. Slowly apply torque until the fastener starts to rotate.

d. Document reading on SET19B Torque form under initial

values.

e. If any measurement is out of specified range: loosen, retorque

to specified value. Record values on SET19B torque

form.

Torque, with crowfoot:

Range: 56-93 N-m (41-69 ft-lbf)

Specified: 65 N·m (663 kgf·cm, 48 ft·lbf)

Torque, without crowfoot:

Range: 62-102 N-m (46-75 ft-lbf)

Specified: 71 N·m (724 kgf·cm, 52 ft·lbf)

5. Verify torque of the left and right lower ball joint attachment bolts

(Fig. 3). Items B1-B4 on SET19B Torque form.

a. Use a 19mm socket to torque bolts.

b. Set torque wrench higher than upper range limit.

c. Slowly apply torque until the fastener starts to rotate.

d. Document reading on SET19B Torque form under initial

values.

e. If any measurement is out of specified range: loosen, retorque

to specified value. Record values on SET19B torque

form.

Torque:

Range: 139-229 N-m (103-169 ft-lbf)

Specified: 160 N·m (1631 kgf·cm, 118 ft·lbf)

6. Verify torque of left and right side front lower control arm Bolts

(Fig. 4) Items C1-C4 on SET19B Torque Form.

a. Use a 22mm socket to torque the front and rear lower

control arm bolts (Fig. 8-2).

b. Set torque wrench higher than upper range limit.

c. Slowly apply torque until the fastener starts to rotate.

d. Document reading on SET19B Torque form under initial

values.

e. If any measurement is out of specified range: loosen, retorque

to specified value. Record values on SET19B torque

form.

Torque:

Range: 152-251 N-m (112-185 ft-lbf)

Specified: 175 N·m (1785 kgf·cm, 129 ft·lbf)

Fig. 2

Fig. 3

Fig. 4

S a f e t y R e c a l l S E T 1 9

5 | P a g e

Southeast Toyota Distributors September 20, 2019

Distributors September 20, 2019

7. Verify Torque of driver side and passenger side tie rod end

locking nuts. (Fig. 5) Items D1 and D2 on SET19B Torque Form.

a. Use a 22mm crowfoot to torque the front and rear lower

control arm bolts.

b. Set torque wrench higher than upper range limit.

c. Slowly apply torque until the fastener starts to rotate.

d. Document reading on SET19B Torque form under initial

values.

e. If any measurement is out of specified range: loosen, retorque

to specified value. Record values on SET19B torque

form.

Torque:

Range: 76-126 N-m (56-93 ft-lbf)

Specified: 88 N·m (897 kgf·cm, 65 ft·lbf)

8. Verify Torque of driver side and passenger side front lower

shock bolts. (Fig. 6) Items E1 and E2 on torque Form.

a. Use a 19mm wrench and 19mm socket to torque the front

lower shock bolts.

b. Set torque wrench higher than upper range limit.

c. Slowly apply torque until the fastener starts to rotate.

d. Document reading on SET19B Torque form under initial

values.

e. If any measurement is out of specified range: loosen, retorque

to specified value. Record values on SET19B torque

form.

Torque:

Range: 82-136 N-m (61-100 ft-lbf)

Specified: 95 N·m (969 kgf·cm, 70 ft·lbf)

9. Reinstall TRD skid plate and verify Torque. (Fig. 7)

a. Use a 14mm wrench torque the front lower shock bolts.

Torque: 30 N·m (306 kgf·cm, 22 ft·lbf)

b. Document Torque on SET19B Torque form.

F1-4 for skid plate

Fig. 5

Fig. 6

Fig. 7

S a f e t y R e c a l l S E T 1 9

6 | P a g e

Southeast Toyota Distributors September 20, 2019

Distributors September 20, 2019

10. Verify Torque of driver side and passenger Rear lower shock

bolt. (Fig. 8) Items G1 and G2 on torque Form.

a. Use a 19mm socket to torque the front lower shock bolts.

b. Set torque wrench higher than upper range limit.

c. Slowly apply torque until the fastener starts to rotate.

d. Document reading on SET19B Torque form under initial

values.

e. If any measurement is out of specified range: loosen, retorque

to specified value. Record values on SET19B torque

form.

Torque:

Range: 82-136 N-m (61-100 ft-lbf)

Specified: 98 N·m (1000 kgf·cm, 72 ft·lbf)

11. Reinstall tire and wheel assemblies (Fig. 9)

a. Torque lug nuts to specification

Torque: 103 N·m (76 ft·lbf)

b. Document Lug Nut Torque on Torque record form.

12. Review Torque form to verify completion.

a. Dealer should retain a copy with the RO.

b. Torque form must be attached to warranty claim submitted

to SET.

Fig. 8

Fig. 9

S a f e t y R e c a l l S E T 1 9

7 | P a g e

Southeast Toyota Distributors September 20, 2019

Distributors September 20, 2019

APPENDIX

A. CAMPAIGN DESIGNATION DECODER

Examples:

SET14A = Launched in 2014, Remedy Phase, 1st Campaign Launched in 2014

SET14B = Launched in 2014, Remedy Phase, 2nd Campaign Launched in 2014

SET15A = Launched in 2015, Remedy Phase, 1st Campaign Launched in 2015

S a f e t y R e c a l l S E T 1 9

8 | P a g e

Southeast Toyota Distributors September 20, 2019

Distributors September 20, 2019

SET19B Torque Validation Form VIN:

FRONT UPPER SHOCK NUTS LEFT SIDE RIGHT SIDE

Initial Value Re-torque Value Initial Value Re-torque Value

A1: A4:

A2: A5:

A3: A6:

Note: “Re-torque Value” is only needed if the “Initial Value” is out of the range:

With Crowfoot: 56-93 N-m (41-69 ft-lbf)

Without Crowfoot: 62-102 N-m (46-75 ft-lbf)

LOWER BALL JOINT ATTACHMENT BOLTS LEFT SIDE RIGHT SIDE

Initial Value Re-torque Value Initial Value Re-torque Value

B1: B3:

B2: B4:

Note: “Re-torque Value” is only needed if the “Initial Value” is out of the range:

139-229 N-m (103-169 ft-lbf)

LOWER CONTROL ARM BOLTS LEFT SIDE RIGHT SIDE

Initial Value Re-torque Value Initial Value Re-torque Value

C1: C3:

C2: C4:

Note: “Re-torque Value” is only needed if the “Initial Value” is out of the range:

152-251 N-m (112-185 ft-lbf)

TIE ROD END LOCKING NUT LEFT SIDE RIGHT SIDE

Initial Value Re-torque Value Initial Value Re-torque Value

D1: D2:

Note: “Re-torque Value” is only needed if the “Initial Value” is out of the range:

76-126 N-m (56-93 ft-lbf)

S a f e t y R e c a l l S E T 1 9

9 | P a g e

Southeast Toyota Distributors September 20, 2019

Distributors September 20, 2019

FRONT LOWER SHOCK BOLTS LEFT SIDE RIGHT SIDE

Initial Value Re-torque Value Initial Value Re-torque Value

E1: E2:

Note: “Re-torque Value” is only needed if the “Initial Value” is out of the range:

82-136 N-m (61-100 ft-lbf)

TRD SKID PLATE LEFT SIDE RIGHT SIDE

Torque Value Torque Value

F1: F3:

F2 F4:

REAR LOWER SHOCK BOLTS LEFT SIDE RIGHT SIDE

Initial Value Re-torque Value Initial Value Re-torque Value

G1: G2:

Note: “Re-torque Value” is only needed if the “Initial Value” is out of the range:

Range: 82-136 N-m (61-100 ft-lbf)

WHEELS LEFT SIDE RIGHT SIDE

Left Front Left Rear Right Front Right Rear

SEOCONTENT-END

2 Affected Products

Vehicle

| MAKE | MODEL | YEAR |

TOYOTA | 4RUNNER | 2018-2019 |

11 Associated Documents

Recall Quarterly Report #2, 2020-1

RCLQRT-19V670-2424.PDF 211.245KB

Loading...

Loading...

Recall Quarterly Report #1, 2019-4

RCLQRT-19V670-6245.PDF 211.15KB

Loading...

Loading...

Recall Quarterly Report #3, 2020-2

RCLQRT-19V670-3059.PDF 211.33KB

Loading...

Loading...

Part 577 Owner Notification Envelope – RONE-19V670-2730

Loading...

Loading...

Owner Notification Letter(Part 577) – SET19B- Issued Owner Notification

RCONL-19V670-8796.pdf 187.266KB

Loading...

Loading...

Defect Notice 573 Report

RCLRPT-19V670-4792.PDF 213.95KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – Subject: Safety Recall SET19B – Remedy Available

RCMN-19V670-6023.pdf 144.535KB

Loading...

Loading...

Recall Acknowledgement

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-19V670-7249.pdf 977.279KB

Loading...

Loading...

Recall 573 Report – Amendment 1

RCLRPT-19V670-2313.PDF 214.033KB

Loading...

Loading...

Recall Quarterly Report #4, 2020-3

RCLQRT-19V670-9029.PDF 211.432KB

Loading...

Loading...

Latest Recalls Documents

- PRECISION - Ships pre-calibrated to +/- 4% accuracy and ready to use. Include calibration certificate with traceable serial number.

- DURABLE - Reinforced ratchet gear head constructed from hardened, heat treated Chrome Vanadium alloy steel.

- LONG-LASTING - Rust & corrosion protection with our unique and newly invented Electro-Black finish treatment.

- PERFORMANCE - Features an easy-to-read, highlighted yellow print dual-range scale. Identify the markings even in low-light conditions.

- COMFORTABLE - Comes with a reversible ratchet head that drives in both directions and measure torque in a clockwise direction.

- Includes 1-pc. 3/8 in. drive torque wrench; Storage case; Product manual with torque conversion chart

- Wrench emits a click that can be heard and felt when the preset value is reached

- Permanently marked, high-contrast dual-range scale is easy to read, even in low light

- Reversible ratchet head drives in both directions and measures torque in clockwise direction

- Durable all-steel construction has no plastic parts to break or wear out

- High Precision and Quick Reading: 3/8 torque wrench has high contrast and dual range scale( 5-45 Ft-Lb/6.8-61 Nm),making it clear and easy to read. We have professional torque wrench production technology, and after 20000 tests, the calibration error range of the torque wrench is around 3%, making it an essential helper for you

- Safe and Reliable Operation: Equipped with a bidirectional drive ratchet head, torque can be measured clockwise or counterclockwise. When the set torque value is reached, a "click" sound will remind you to stop applying force to prevent damage to the item due to excessive torque

- Good Quality and Durable Material: Made of hardened chromium vanadium steel alloy (Cr-V). At the same time, the bottom buckle tail plug adopts a red anodizing process to improve the product's oxidation resistance during use and enhance surface wear resistance. 72 tooth ratchet head, made of chromium molybdenum steel.We use the quality materials which are resist corrosion and are durable

- Quick Torque Setting: Simple and fast torque setting, pull down the locking knob and hold it down to rotate to the torque you need. Release the hand and the locking knob will automatically rebound to lock the torque value. And the designer referred to the appearance of the flashlight handle and designed a non slip and labor-saving knurled handle, making it more comfortable and easy to hold when using

- Easy to Store and Widely Use: You will receive the 3/8-inch drive click torque wrench with a sturdy plastic shell storage box, which is very delicate and durable. Torque wrench is suitable nuts and bolts on various occasions, such as bike, motorcycle, car spark, and torque wrench is suitable for repairing cars and motorcycles, which are essential maintenance tools for car owners

- Durable Ratchet Head: Made from Hardened treated Chrome Vanadium steel alloy (Cr-V) Corrosion-Retardant: Satin Finish. Made in Taiwan

- Easy Storage: A sturdy plastic storage case is included. Non-Slip Grip: Knurled handle

- Easy to Read: High Contrast & Dual Range Scale. Accurate: Pre-Calibrated to ± 4%

- Accessories included: 1/2" Drive 5" long Extension Bar

- Simple and Reliable: “Click” sound tells the preset torque value is reached. Stop applying force when you hear and feel it.

- ±3% HIGH PRECISION AND COOL APPEARANCE: 1/2 inch drive torque wrench (10-170ft.-lb/13.6-230.5Nm)has a calibration error range of ±3%, high precision, and comes with a corresponding serial number, which is easy to trace the original data, and you can use it with confidence.Hairich torque wrench not only has superior quality but also has a superior appearance. The classic combination of black and red is fashionable and textured, allowing you to enjoy a visual feast during use.

- PREMIUM MATERIAL AND DURABLE: Experience the ultimate durability and antiskid with the torque wrench. The main body of Hairich torque wrench set is made of chrome vanadium steel alloy, which is more strong and more durable. The head of the inch-pound torque wrench adopts a ratchet design with a reversing device to improve work efficiency. The square knurled handle is made of aluminum titanium alloy, which is ergonomic and comfortable to hold for long-time use.

- DUAL SCALE AND QUICK SETTING: Laser Printed by dual-range(ft-lb and Nm). Our professional torque wrench is easy to read and provides direct unit conversion, When the set torque value is reached, the torque wrench will make an audible and felt click to remind you to stop applying force. Pull down the lock knob and hold it until the torque setting is completed. Release the hand, and the lock knob will automatically rebound back to lock the value.

- ERGONOMIC DESIGN AND POWERFUL: Every design of our industrial torque wrench conforms to ergonomic, easy to handle.72-tooth ratchet, 5° ratcheting arc head, a quick-release button for easy loading and unloading, and an aluminum non-slip handle for excellent grip and control. A recent research review that, 72-tooth ratchets are very professional tooth ratchets, you just only rotate 5 degrees to finish it. Not easy to slip and wear, can be used in small spaces, and is more durable and powerful.

- EASY OPERATION AND SAFETY: Thanks to its bidirectional drive ratchet head, our torque wrench can be measured both clockwise and counterclockwise. When the set torque value is reached, a "click" sound will remind you to stop applying force to prevent damage to the item due to excessive torque. Notice: At low Nm settings under 5 Nm the "click" sound can be too light to hear.

- Portability: durable case for portability or storage

- Added comfort: bi-material handle for comfort and grip

- Hassle free use: locking feature adjusts quick and easily for hassle free use

- Quick identification: scales stamped into housing showing inch and metric torque setting

- Meets or exceeds ASME specifications

- 🔧【𝐌𝐢𝐥𝐢𝐭𝐚𝐫𝐲-𝐠𝐫𝐚𝐝𝐞 𝐒𝐭𝐞𝐞𝐥】ETOOLAB torque wrench utilizes military-grade steel as its base material, coupled with professional surface rust protection methods tailored to usage habits. While ensuring user comfort, it enhances product strength, wear resistance, and rust resistance. offers a more comfortable experience and a longer lifespan!

- ⚙️【±𝟑% 𝐏𝐫𝐞𝐜𝐢𝐬𝐢𝐨𝐧 & 𝐒𝐢𝐦𝐩𝐥𝐞 𝐋𝐨𝐜𝐤𝐢𝐧𝐠 𝐑𝐢𝐧𝐠】Our torque wrench 3/8 drive meets the high precision standard of ±3% and comes with a traceable serial certificate. You can use it with confidence! Moreover, its graduation ring is tightly locked, with smaller incremental values, ensuring precise and consistent torque output even after multiple uses. This reduces the hassle of frequent adjustments. It is undoubtedly an excellent tool for your work!

- 👍【𝐄𝐚𝐬𝐲-𝐭𝐨-𝐑𝐞𝐚𝐝】The scale of this 3/8 drive torque wrench is laser-engraved, using a black background with white markings. dinamometrica de 3/8 ensures clear and easy readability of the scale, even in sunlight. With a dual-scale design, users can conveniently read torque values in two different units according to their preferences, without the need for conversion!

- 🔊【𝐋𝐨𝐮𝐝 𝐂𝐥𝐢𝐜𝐤 𝐒𝐨𝐮𝐧𝐝】This torque wrenches has been upgraded to have a louder "Click" sound. We conducted over 25,000 tests to ensure that each product produces a click sound volume of no less than 45dB when the torque value exceeds 34 lbf·ft. When you hear the distinct click sound, it indicates that the preset torque has been reached, signaling you to stop applying force. You no longer need to worry about damaging your mechanical components.

- 💯【𝐔𝐬𝐞𝐫-𝐅𝐫𝐢𝐞𝐧𝐝𝐥𝐲】Our torque wrench set features a 72-tooth dual-directional ratchet head, allowing for easy operation in both clockwise and counterclockwise directions. It is designed with an adjustable locking ring, making it effortless to adjust the preset torque value.

- 【8-in-1 Torque Wrench Set】 Includes 1/4, 3/8, 1/2 inch drive torque wrenches that meet your different needs. 5Pcs Adapter: 1/4"Extension bar(4''), 3/8"Extension bar(6''), 1/2"Extension bar(5''), 3/8" Universal Joint, 1/2" to 3/8" Adapter with a sturdy plastic case for storage and portability

- 【Dual range scale & High Precision】 1/4 inch 10-220in.lb/1-24.7Nm with 1 in.lb micro-adjustment, 3/8 inch 10-45ft.lb/13.6-61Nm with 0.25 ft.lb micro-adjustment, 1/2 inch 10-160ft.lb/10-227Nm with 1 ft. lb micro-adjustment. Each wrench undergoes strict and specialized instrument testing before leaving the factory to ensure accuracy within ±3% and is provided with a formal calibration certificate

- 【Safe & Reliable】 This torque wrench set has been upgraded to have a louder "Click" sound, ensuring a clear and stronger click sound when the torque value exceeds 5 Nm, subtler click at lower than 5 Nm. The distinct click sound indicates that the preset torque has been reached, signaling you to stop applying force

- 【Releasable & Dual Direction】These torque wrenches has a quick release button with which accessories can easily be installed and removed, the accessories can grip and is not easy to fall down. With 72-tooth reversible ratchet head, it can be used in both clockwise and counterclockwise directions

- 【High Quality and Durable】 The torque wrench ratchet head is made from hardened treated Cr-Mo Steel for longevity. Handle crafted from high-grade aerospace aluminum for durability, and corrosion resistance. All adapters are treated with phosphating, with stronger wear resistance and a longer lifespan

- 🎯 GOYOJO Precision Promise - Experience unmatched accuracy with the GOYOJO Digital Torque Wrench. Engineered for precise results with ±2% clockwise and ±2.5% counter-clockwise accuracy, it embodies our commitment to excellence in every turn.

- 🔧 Versatility, the GOYOJO Way - Whether it's automotive, bike repairs, or home DIY, our torque wrench adapts to your needs. GOYOJO's dedication to versatile and multifunctional tools shines through, making it an indispensable part of your toolkit.

- 🔄 GOYOJO's Innovative Touch - Stay ahead with our innovative Peak and Trace modes. These unique features, a testament to GOYOJO's forward-thinking design, provide real-time feedback for on-the-go adjustments, setting us apart in the tool industry.

- ⚙️ Durability Meets Design - Crafted from superior carbon steel, the GOYOJO Digital Torque Wrench is a beacon of durability and user-friendly design. This product highlights our ethos: to combine longevity with ease of use for every customer.

- 🌙 Ergonomic Excellence by GOYOJO - Feel the difference with our ergonomically designed handle for comfortable, prolonged use. The large, backlit LCD display, a signature GOYOJO feature, ensures visibility in all working conditions, reflecting our focus on user-centric design.

- 3Pcs Torque Wrench Set: The calibration error range is around 3%, each torque wrench has a calibration certificate. The 3-in-1 torque wrench set can meet your different needs. Including 1/4 inch 20-240 in.lb, 3/8 inch 5-45 ft.lb, 1/2 inch 20-160 ft.lb.

- Safe and Reliable: When the 1/2 torque wrench reaches the preset torque value, it makes a clear "click" sound, accompanied by an obvious hand vibration that reminds you no longer to apply force, prevent damage caused. 72-tooth reversible ratchet head, it can be used both clockwise and counterclockwise directions.

- Quick Release Button: This 3/8 torque wrench has a quick release button with which accessories can easily be installed and removed, the accessories can grip and is not easy to fall down. It is more convenient to use. The torque wrench is made of CR-MO with a higher hardness.

- Easy to Set: First pull down the locking knob and hold it down and then start setting the desired torque value. Release the hand and the locking knob will automatically rebound to lock the torque value. If you do not use, please set the torque key to the minimal torque value.

- Widely Use: The torque wrenches can satisfy you in bicycle, motorcycle, car, truck and wheel screws, wheel nuts and in the device installation, electrical engineering, etc. We insist on bringing customers a good shopping experience.

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.